8

HS9385-2 Housings

These housings are to be connected to 24VAC, and

are designed for use where site power is 24volts. The

HS9385-2 housings should only be used with 24volt

cameras. The integral heater/defogger requires 24volts.

The housing is shipped with the heater/ defogger

connected to the terminal block.

Installing a 24 volt camera

into the HS9385-2 housing

simply requires the two flying leads be attached to the

camera's terminal block. See FIGURE 10.

HS9385-5 Housings

These housings are to be connected to 230VAC, and

are designed for use where site power is 230volts. The

HS9385-5 housings should only be used with 230volt

cameras. The integral heater/defogger requires

230volts. The housing is shipped with the

heater/defogger connected to the terminal block.

Installing a 230 volt camera

into the HS9385-5

housing simply requires the camera's line cord to be

plugged into the Schuko inline receptacle provided.

See FIGURE 10.

FIGURE 10 Camera Connections

5.9

Video Coax Connection

WARNING: Only use the cables specified

under INSTALLATION, Cable Requirements for

wiring of the video coax connection.

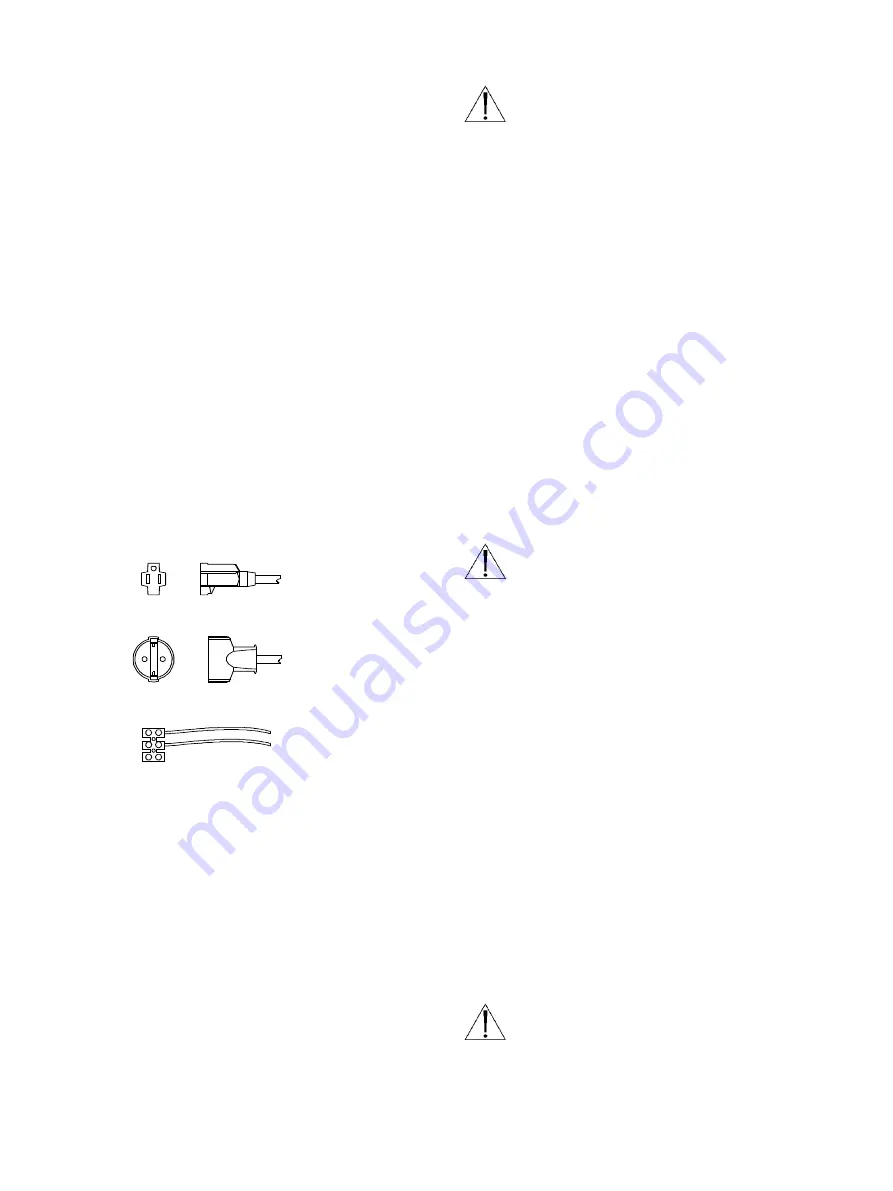

If lens control or feed-through wires will be used:

1. Install the long flexible portion of the small

liquid-tight fitting on the video coax cable and

pull the cable through the small fitting on the

rear end of the base assembly. The fitting will

accept cables with diameters from 4.6mm

(0.181in.) to 7.9mm (0.312in.). See FIGURE 11.

2. Attach a BNC connector to the coax and connect

it to the camera. Pull any excess cable through

the liquid-tight fitting and tighten the flex fitting

to 4.0N-m to 4.5N-m (35in. lb to 40in. lb). This

torque rating is approximately 1 to 1 1/2 turns

past the point that the fitting starts to grip the

cable. Failure to do so will result in water

damage to all electronic parts. Use a tie wrap

(included) to provide strain relief on the video

cable at the exit point (inside the unit).

Be sure to securely tighten all fittings to ensure

a liquid-tight seal. Not doing so could damage

the camera, the housing, or both.

If no lens control or feed-through wires will be used:

1. Install the long flexible portion of a large

liquid-tight fitting on the video coax cable and

pull the cable through the large right fitting on

the rear end of the base assembly. Refer to

FIGURES 11 and 12.

2. Attach a BNC connector to the coax and

connect it to the camera. Pull any excess cable

through the liquid tight fitting and tighten the

flex fitting to 8.5N-m to 9.0N-m (75in. lb to

80in. lb). This torque rating is approximately

1 to 1 1/2 turns past the point that the fitting

starts to grip the wire. Failure to do so will

result in water damage to all electronic parts.

Use a tie wrap (included) to provide strain relief

on the video cable at the exit point (inside the

unit).

Be sure to securely tighten all fittings to ensure

a liquid-tight seal. Not doing so could damage

the camera, the housing, or both.

24 VAC (-2)

Flying Leads

115 VAC (-1)

Nema 5-15R

Receptacle

230 VAC (-4)

Schuko Inline Socket

Receptacle