30

WIRING

DIAGNOSIS(

Terminal Block Wiring Diagnosis

)

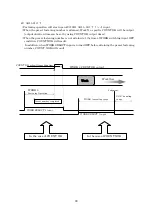

Wiring diagnosis will be performed through monitoring input status of external wires mated to

UTM-1500 Input Terminal Block and through Output Terminal Block forced output.

(1)

Input Wiring Diagnosis

・○

indicate the absence of Terminal Block input

・●

indicate the presence of Terminal Block input

(2)

Output Wiring Diagnosis

・

Select any of the terminals by touching

. The selected terminal will accompany “_“ at

the bottom.

・

Press

key to switch between the selected output terminal’s ON/OFF.

・

At the start of WIRING DIAGNOSIS screen, OUT 1~5 will be under OFF “

○

” state and VALVE

will be under ON “

●

” status.

WIRING DIAGNOSIS

1 2 3 4 5 6 V

IN : ○ ○ ● ● ○ ○

OUT: ● ○ ● ○ ● ●

Display Layout

1~6:

Terminal Block No.

(IN1~6・OUT1~5)

V:VALVE

Terminal

○:

Terminal’s input or output is OFF condition.

●:

Terminal’s input or output is ON condition.