SPECIFICATIONS

Important Warnings - Sanders & Polishers

1. Eye protection, safety gloves and safety aprons must always we worn when operating a sander or

polisher.

2. Never adjust the sander or polisher or change the backing pad, sanding disc, sanding belt or

polishing bonnet unless the air supply and air hose is disconnected from the tool

3. Only use backing pads and polishing backing pads that have a rated speed then same as the sander

or polisher or higher.

4. Never attempt to modify or adapt a sander or polisher for use with a grinding wheel or cut-off wheel

or wire brush.

5. Only personnel trained in the correct methods to change pads, sanding discs, sanding belts and

polishing bonnets should conduct these operations.

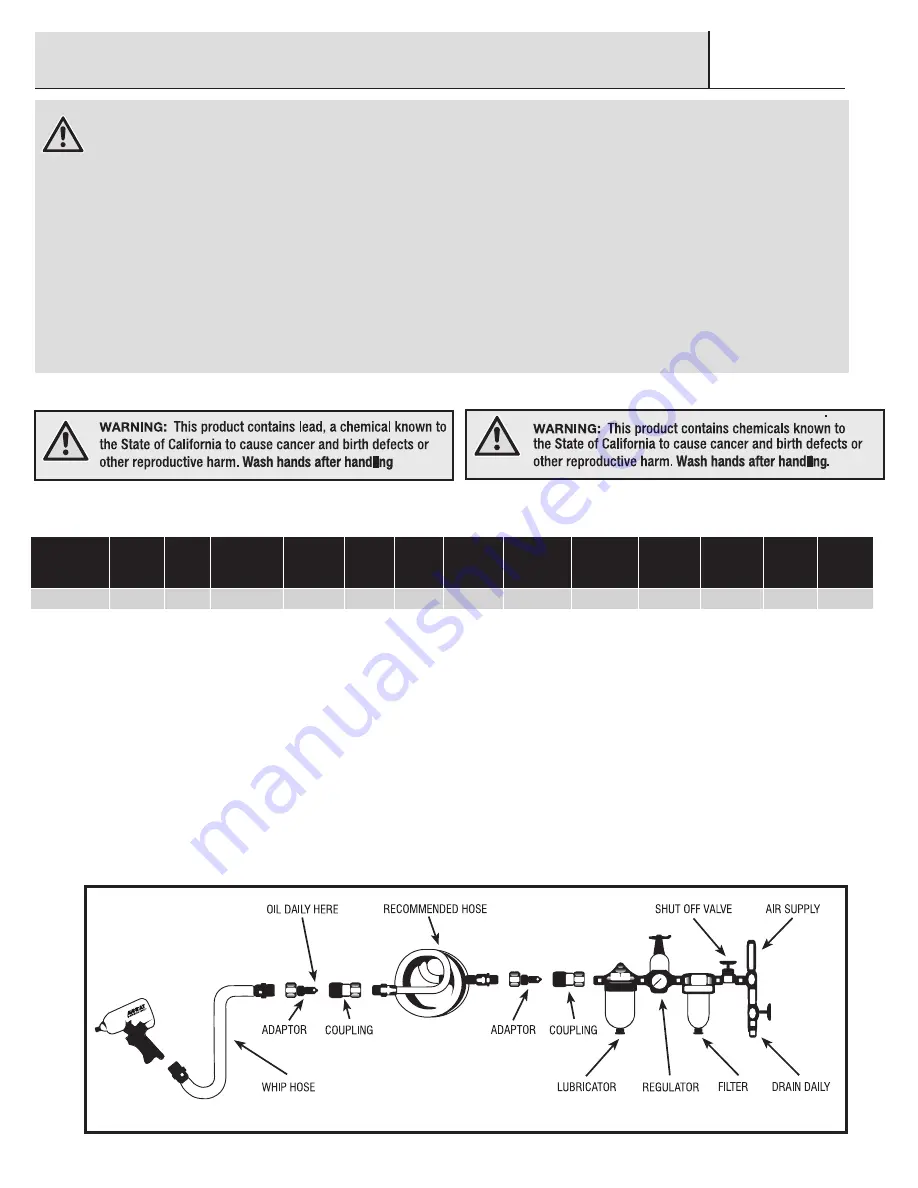

Tools of this class operate on a wide range of air pressure. It is recommended that air pressure of these tools measures 90 PSI at the tool while running free. Higher

pressure and unclean air will shorten the tool’s life because of faster wear and may create a hazardous condition and void the warranty. Water in the air line will

cause damage to the tool. Drain the air tank daily. Clean the air inlet filter screen on at least a weekly schedule. The recommended hookup procedure can be viewed

in the illustration below. The air inlet, used for connecting air supply, has standard 1/4” NPT American Thread. Line pressure should be increased to compensate for

unusually long air hoses (over 25 feet). Minimum hose diameter should be 3/8” I.D. and fittings should have the same inside dimensions.

Air Supply

Model No.

Pad Size

(in)

Orbit

(in)

Pad Type

No.

Vacuum

Pad Holes

Free

Speed

(RPM)

Weight

(lbs)

Length w/

Pad Fitted

(in)

Width w/

Pad Fitted

(in)

Height w/

Pad Fitted

(in)

Noise Level

d(B)A

Vibration

m/sec2

Average

Air (CFM)

Air Inlet

(in.) NPT/

BSP

6700-5-336

5

3/16

Hook & Loop

0

11,000

2.0

6.7

5.0

4.3

75

0.8

1.6

1/4

Summary of Contents for 6700-5-336

Page 1: ...MODEL 6700 5 336 5 Orbital Palm Sander...

Page 4: ......