6

MN-282

If the upper bracket cannot be positioned in the middle of the frame, when the assembly is

set onto the axle, using the threaded portion of the tool (ie. bracket falls short but is at the

top of the threads) use the optional spacers noted in fig. 1 to raise the assembly back up so

the threaded usable portion of the tool can be used to position the bracket correctly on the

frame. Be sure to leave 1.50” above the bracket for valve clearance as stated.

CAUTION

NOTE

3.

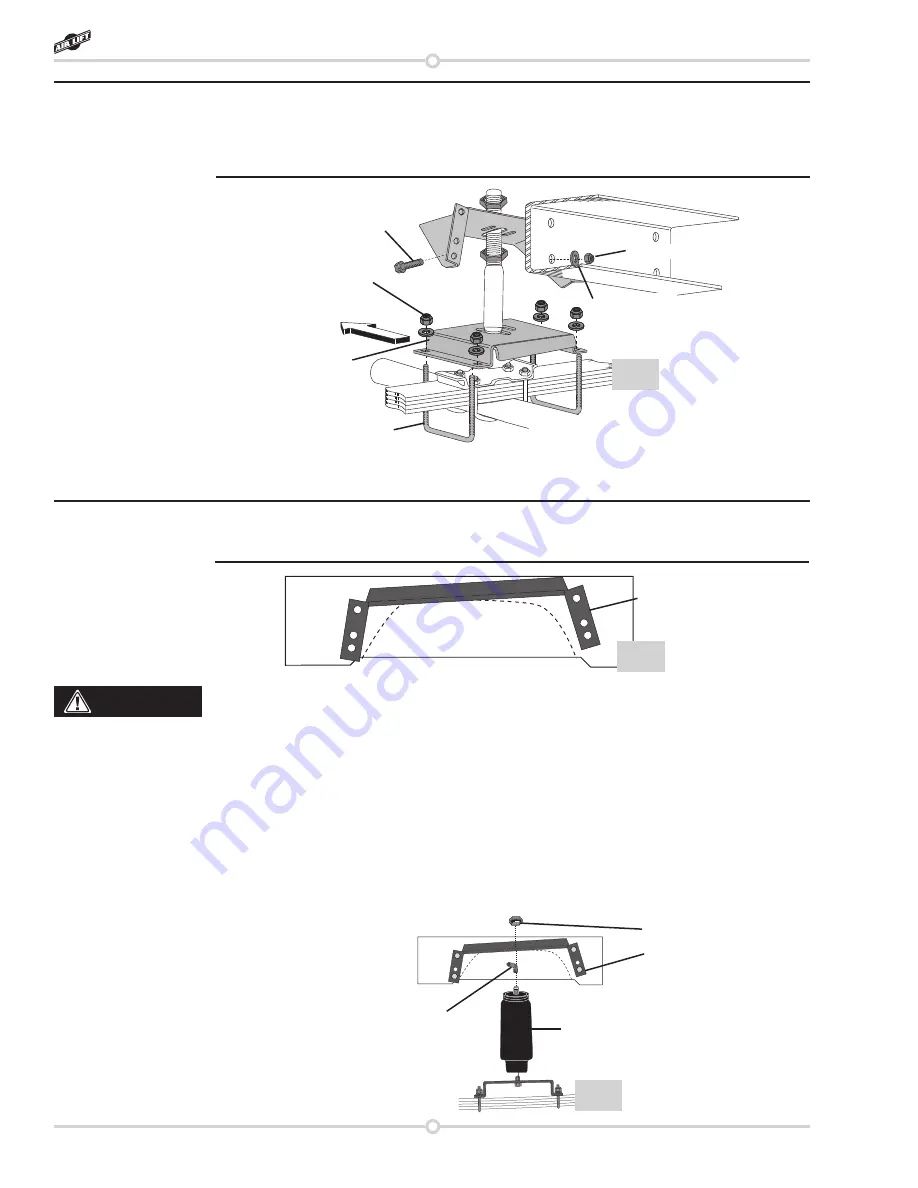

Attach the lower bracket as shown in fig. 4 using the u-bolts, flat washers and lock nuts.

Tighten nuts to 20 ft/lbs.

The frame has an indented area directly over the axle. Normally the upper bracket will span

this indented area. If the flange of the upper bracket falls onto or just inside the radiused

edges of the indent, it is ok. Drill and fasten tight to that rounded surface (fig. 5).

DO NOT DRILL HOLES INTO THE FRAME UNTIL ANY HYDRAULIC LINES, GAS LINE AND

ELECTRICAL WIRES HAVE BEEN MOVED ASIDE ON BOTH SIDES OF FRAME RAIL.

4.

Using the upper bracket as a template, centerpunch one of the lower mounting holes

and drill a 3/8” hole through the frame. Install one of the mounting bolts and LOOSELY

attach the oversized flat washer and locknut. Now centerpunch and drill a 3/8” hole at the

other lower mounting hole location. DO NOT insert the mounting bolt at this time (fig. 4).

5.

You can now remove the installation tool by removing the upper nylon nut, loosening and

removing the tool from the bottom bolt (leave in place), and slightly rotating the upper

bracket to give you enough room to completely remove the tool.

6.

Rotate the upper bracket back to the original location and install the frame bolt, oversized

flat washer and locknut through the second hole you drilled. Now tighten both of the

installed fasteners to 20 ft/lbs. Drill the other two holes and install the fasteners. Torque

to 20 ft/lbs (fig. 6).

OUTBOARD

fig. 4

U-bolt

Nyloc nut

Flat washer

3/8” Frame bolt

Nyloc nut

Flat washer

fig. 5

Upper bracket

Indented area

NOTE

fig. 6

Elbow fitting

Air spring

3/8” Frame bolt

Nylon nut

RideControl