6

MN-751

WirelessONE

RECOMMENDED COMPRESSOR LOCATIONS

Important

LOCATE COMPRESSOR IN DRY, PROTECTED AREA ON VEHICLE.

DIRECT SPLASH OR EXCESSIVE MOISTURE CAN DAMAGE

THE COMPRESSOR AND CAUSE SYSTEM FAILURE.

Disclaimer: If you choose to mount the compressor outside the vehicle please keep in mind

the compressor body must be shielded from direct splash.

Please also remember . . .

• To avoid high heat environments.

• To avoid mounting the compressor under the hood.

• To check to be sure the compressor harness #2 will reach the compressor and

connect to harness #1.

• The compressor can be mounted in any position — vertical, upside down, sideways,

etc. (Please refer to the instruction manual).

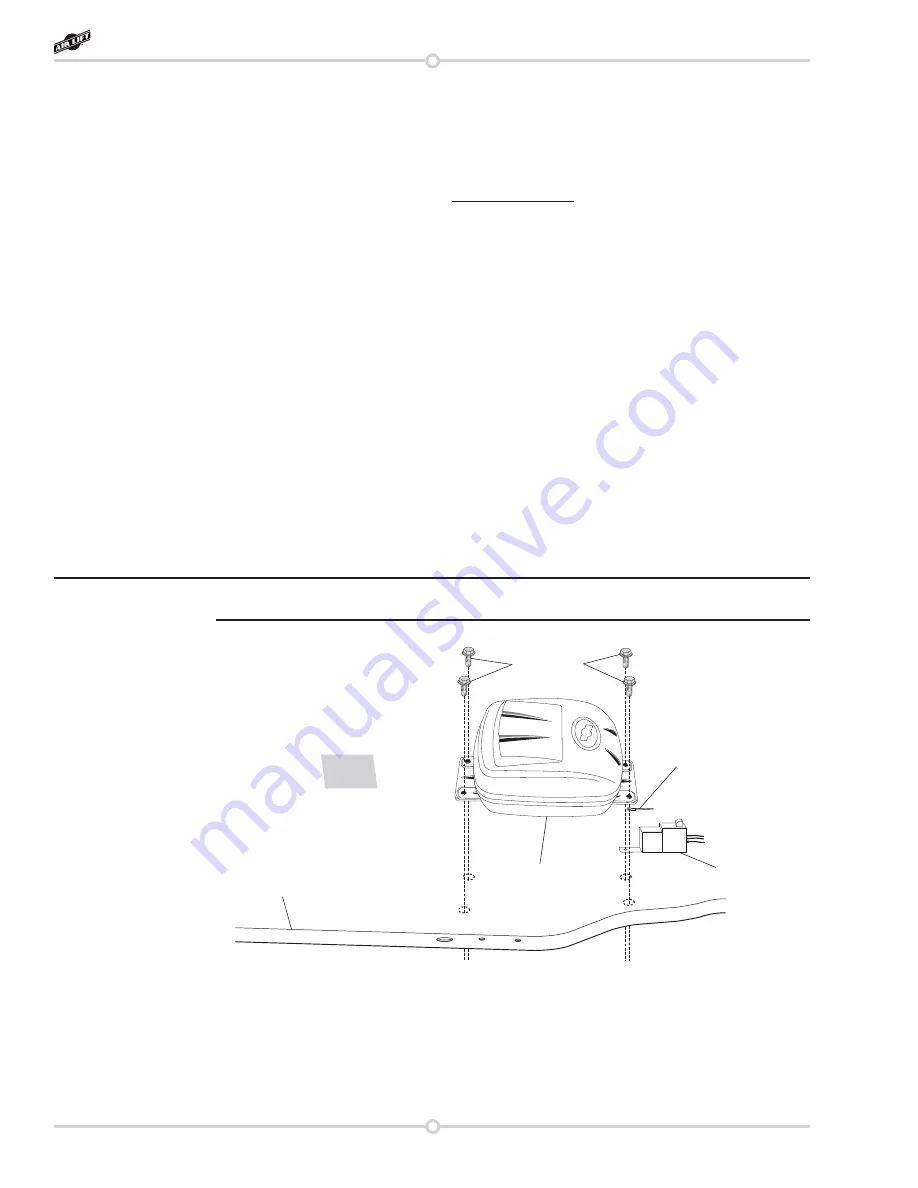

INSTALLING THE COMPRESSOR

1. Select a rigid mounting location for the compressor on the vehicles frame or crossmember

(fig. 3) that shields the compressor from the elements and heat sources.

The electrical harness will force the compressor to be within 24” of the manifold in order to

make electrical connections.

2. Use the supplied self tapping fasteners to fasten the compressor to the frame or cross

member.

• One of the self tapping screws will be used as an electrical ground for the

compressor ring terminal.

• Another of the self tapping screws can be used to mount the compressor relay.

Compressor

Frame

Relay

Compressor Ground

Self-tapping

Screws

fig. 3

Installing the WirelessONE System

NOTE