AIR TORQUE

The 4th Generation

Maintenance

4)

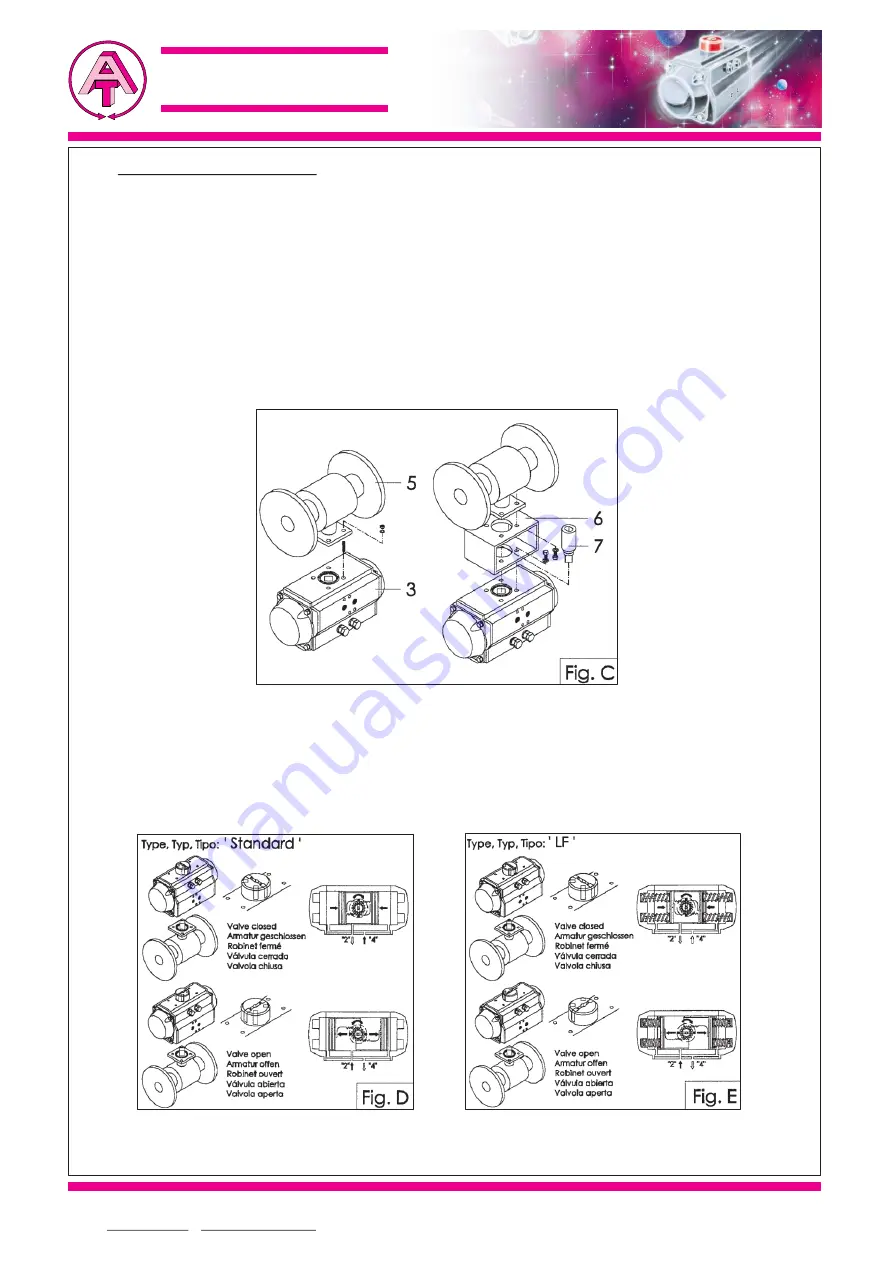

Assembly of Valve Figure C:

Before proceeding with the assembly of a valve onto an actuator be sure that the actuator

operates in the desired direction of rotation and both actuator / valve are correctly orientated.

Important : When using a spring return actuator for a fail safe operation, ensure that when air or

electricity failure occurs the direction of rotation is correct for your application.

Fit the valve 5 onto the actuator 3. Ensure that the actuator is in normal position (closed posi-

tion). There are two types of valve assembly onto the actuator :

-Direct-mount : Fit the square of the valve 5 directly into the square of the actuator 3 and bolt

together through the valve ISO pad (max. tightening torque see table above).

-Bracket-mount : Mounting with a bracket 6 and coupling 7, the bracket is bolted to the actua-

tor / valve to join them together and the coupling is used to connect the actuator output drive

to the valve stem (max. tightening torque see table).

1)Mounting alternatives :

2)Valve mounting with Actuator Type STANDARD (Clockwise to close) Figure D :

5.4.3) Valve mounting with Actuator Type LF (Clockwise to open) Figure E :

Via Alla Campagna n.1 * I - 24060 Costa di Mezzate (BG)

Phone: 0039-035-682299 * Fax: 0039-035-687791

e-mail: info@airtorque.it * http://www.airtorque.it

Modifications reserved. Date 02.2000.

No guarantee for accuracy.

Older data sheets are invalid.

Maintenance

905e