AIR TORQUE

AIR TORQUE

AIR TORQUE

The 4th Generation

Maintenance

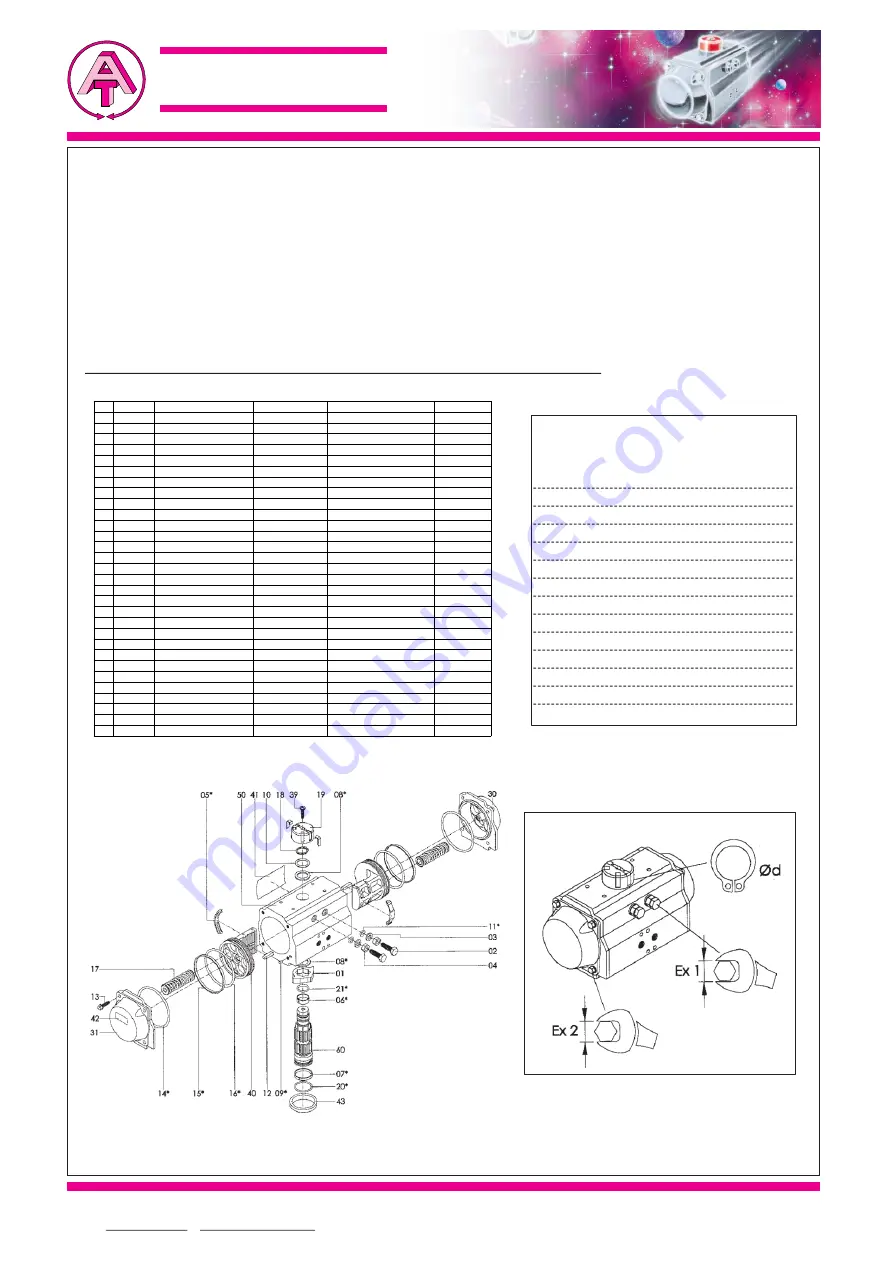

*Spare Part

(1)

AlSi420 Type DR/DL, SC/SO 15-150; GS400-15 Type DR/DL, SC/SO 220-4000

(2)

8 pcs. Type DR/DL, SC/SO 15-1200; 12 pcs. Typ DR/DL, SC/SO 3000

(3)

Type DR/DL, SC/SO 600-3000 End Caps are symmetric

Pos.

Pcs

Part Description

Material

Specification

Protection

01

1

Octi-Cam

(Stop Arrangement)

1.4021/GS400-15

(1)

EN 10088-3/ISO 1083

(1)

02

2

Stop Cap Screw

B8 CI.2

ASTMA193

03

2

Washer

(Stop Cap Screw)

A2

ISO 3506

04

2

Nut

(Stop Cap Screw)

A2-70

ISO 3506

05*

2

Bearing

(Piston Back)

PPA

Amodel ET1001HS

06*

1

Bearing

(Pinion Top)

PA46

Stanyl TW300

07*

1

Bearing

(Pinion Bottom)

PA46

Stanyl TW300

08*

2

Thrust Bearing

(Pinion)

PPA

Amodel ET1001HS

09*

2

Plug

(Transfer Port)

NBR

NBR 70Shore

10

1

Thrust Washer

(Pinion)

1.4301

EN 10088-3

11*

2

O' Ring

(Stop Cap Screw Seal)

NBR

NBR 70Shore

12

2

Piston Guide

PPA+45%GF

Amodel AS1145

13

8/12/16

(2)

Cap Screw

(End Cap)

A"-70

ISO 3506

14*

2

O' Ring

(End Cap)

NBR

NBR 70Shore

15*

2

Bearing

(Piston Head)

PPA

Amodel ET1001HS

16*

2

O' Ring

(Piston)

NBR

NBR 70Shore

17

min.4/max.12

Spring

(Cartridge)

SiCr

Spring Alloy Steel

DIN 17223 Part 2

Epoxy coated

18

1

Spring Clip

(Pinion)

C75

DIN 17223

ENP

19

1

Position Indicator

PP+30%GF

Hostalen PPN VP7790 GV 2/30

20*

1

O' Ring

(Pinion Bottom)

NBR

NBR 70Shore

21*

1

O' Ring

(Pinion Top)

NBR

NBR 70Shore

30

1

(3)

Right End Cap

GD-AlSi8.5Cu3.5Fe

UNI 5075

A, B, C, D, E, P

31

1

(3)

Left End Cap

GD-AlSi8.5Cu3.5Fe

UNI 5075

A, B, C, D, E, P

39

1

Cap Screw

(Indicator)

A2-70

ISO 3506

40

2

Pistons

GD-AlSi8.5Cu3.5Fe

UNI 5075

anodized

41

1

Identification Label

Polyester Aluminium

42

2

Label

(End Cap)

Polyester Aluminium

43

1

Spigot

Alloy 6082

ASTM B221

Alodur

50

1

Body

Alloy6083

ASTM B221

A, B, C, D, E, P

60

1

Drive Shaft

A105

ASTMA105

ENP

6) MAINTENANCE INSTRUCTION

With the information given below, AIR TORQUE provides the end user with all the required infor-

mation necessary for maintenance. Under normal operating conditions the actuator requires only

periodic observation to ensure proper adjustment.

Rebuilding of the AIR TORQUE actuators is allowed only to the personnel of AIR TORQUE or to

personnel which are properly instructed. By contravention the guarantees expires!

Spare kits for maintenance are available to replace all seals and bearings (Soft components listed

in table) that may be necessary between 500,000 and 1,000,000 cycles depending on ope-

rating and/or environmental conditions.

6.1) Drawing with itemised component and recommended spare parts

EX1

EX2

ø d

mm

mm

mm

AT 051/054

10

8

14

AT 101/104

10

10

16

AT 201/204

13

10

22

AT 251/254

13

10

25

AT 301/304

17

13

26

AT 351/354

19

13

36

AT 401/404

19

17

38

AT 451/454

22

17

45

AT 501/504

22

19

48

AT 551/554

24

19

52

AT 601/604

30

22

58

AT 651/654

30

24

68

AT 701/704

36

22

80

AT 801/804

Via Alla Campagna n.1 * I - 24060 Costa di Mezzate (BG)

Phone: 0039-035-682299 * Fax: 0039-035-687791

e-mail: info@airtorque.it * http://www.airtorque.it

Modifications reserved. Date 01.2005.

No guarantee for accuracy.

Older data sheets are invalid.

Maintenance

906e