SPECIFICATIONS

Important Warnings - Impacts

1. Eye protection and hearing protection and safety gloves must always be worn when operating an impact wrench or impact

driver.

2. When using heavy impact sockets or sockets on impact wrenches with 3/4” drive anvils or larger, a socket retaining ring

and pin should be used to prevent the socket falling off and causing injury.

3. Use only impact sockets and accessories. Only use sockets designated “FOR USE WITH IMPACT WRENCHES”, hand tool

damage and replace when necessary.

Accessory Hazards

4. Disconnect the assembly power tool for threaded fasteners from the energy supply before changing the inserted tool or

accessory.

5. Do not touch sockets or accessories during impacting as this increases the risk of cuts, burns or vibration injuries.

6. Use only sizes and types of accessories and consumables that are recommended by the assembly power tool for threaded

fasteners manufacturer; do not use other types or sizes of accessories and consumables.

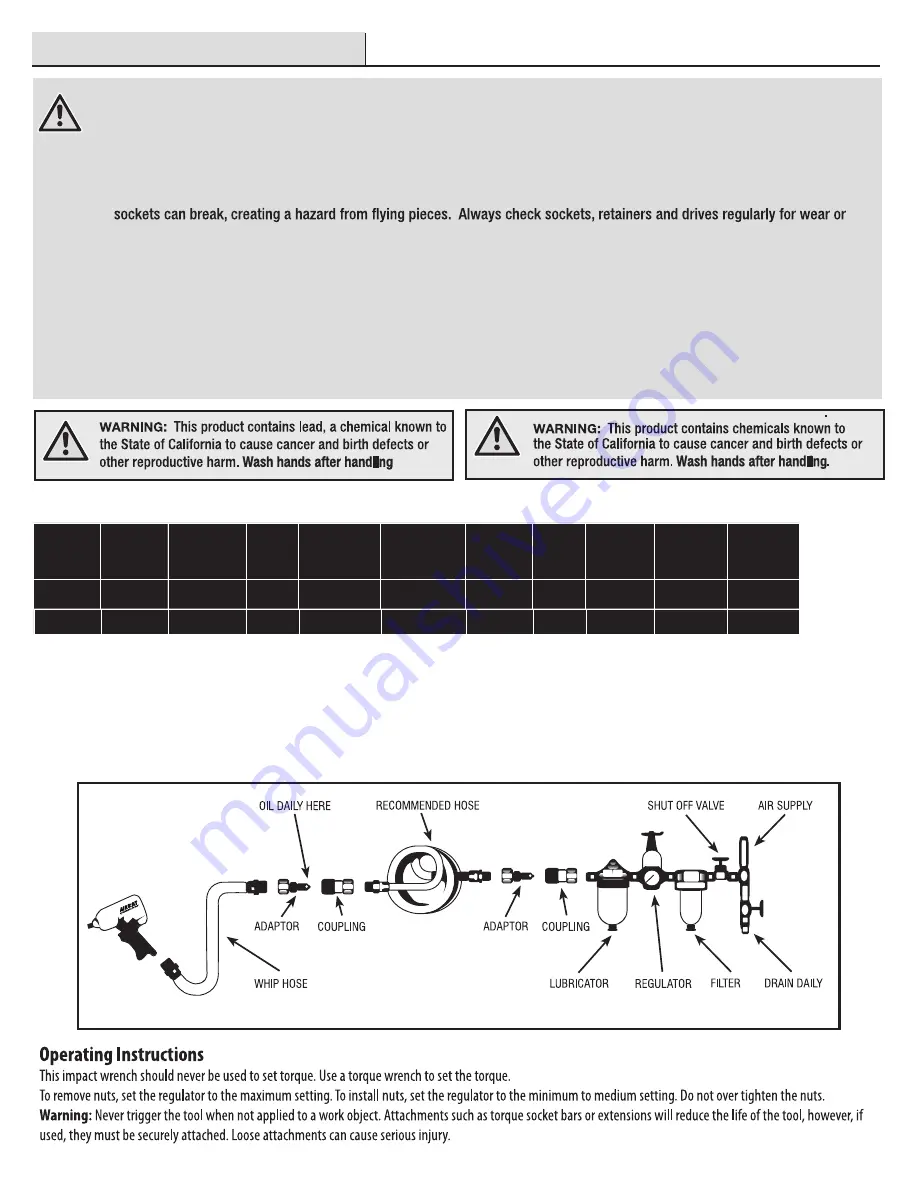

Tools of this class operate on a wide range of air pressure. It is recommended that air pressure of these tools measures 90 PSI at the tool while running free. Higher

pressure and unclean air will shorten the tool’s life because of faster wear and may create a hazardous condition and void the warranty. Water in the air line will

cause damage to the tool. Drain the air tank daily. Clean the air inlet filter screen on at least a weekly schedule. The recommended hookup procedure can be viewed

in the illustration below. The air inlet, used for connecting air supply, has standard 1/4” NPT (US) or BSP (UK). Line pressure should be increased to compensate for

unusually long air hoses (over 25 feet). Minimum hose diameter should be 3/8” I.D. and fittings should have the same inside dimensions.

Air Supply

Model No. Free Speed

(RPM)

Bolt Capacity

(in.)

Square

Drive

(in.)

Impacts Per

Minute

Max. Torque

(ft-lb) @90 psi

Weight

(lbs.)

Length

(in)

Air Cons.

(CFM)

Rec. Hose

Size

(in.)

Air Inlet

(in.)

1076-XL

9,000

9/16

3/8

1650

550

2.5

4.25

8

3/8

1/4

9,000

9/16

1650

550

2.5

4.25

8

3/8

1/4

1056-XL

1/2