13

Pre-fi lters

Pre-fi lters should be checked each month. In most cases, they should be changed every 1 to 3

months. Prefi lter replacement is required when discoloration of the prefi lter occurs or when the low

airfl ow alarm comes on. See the “PRE-FILTER CHECK/REPLACEMENT” section of this manual

for complete instructions.

HEPA Filters

The HEPA fi lter must be changed atlease every two years

must be changed atlease every two years. See the “FILTER REPLACEMENT”

section of this manual for complete instructions.

The HEPA fi lter must be changed every two years or whenever it is clogged. The frequency with

which the fi lter must be changed depends upon usage. OSHA and the American Conference of

Government Industrial Hygienists (ACGIH) have published guidelines for Threshold Limit Values

(TLV’s) of exposure to chemicals and particulate. Local regulations may also contain specifi c

TLV’s. It is the express responsibility of the user to follow these regulations.

If the level of the substance being used exceeds the published TLV’s prior to the annual change

date, the HEPA fi lter must be changed. If the fi lter is changed prior to the annual date, it should be

changed every two years from this new date.

Pre-fi lter Check / Replacement

A. To check the Pre-fi lter:

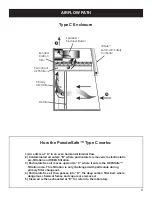

1. Look through the sash to the inside of your unit. The pre-fi lter and pre-fi lter grid are located at the back of

the unit.

2. Look through the slats on the pre-fi lter grid. If the prefi lter is discolored (the original color is green),

replacement is needed.

B. To replace the Pre-fi lter:

1. Don the proper PPE for handling the substance that have been used inside the hood (refer to the MSDS

sheets).

2. Turn the unit on and make sure that the blower is running.

3. Place an appropriate poly bag on the base of the enclosure. You will place the saturated pre-fi lter inside

the bag and seal it before removing it from the hood.

4. Remove the 4 black knobs or 6 polypropylene clips that hold the prefi lter grid in place. This will expose

the clogged pre-fi lter. Do not remove the pre-fi lter from the hood!

5. Remove the pre-fi lter from the pre-fi lter grid and place it inside the poly bag. Wipe any residue off of the

pre-fi lter grid and base of the enclosure. Place the rag inside the bag with the pre-fi lter and seal the bag.

Dispose of the pre-fi lter in accordance with your local guidelines for the substances that have been used

inside the hood.

6. Inspect the HEPA fi lter for blockage. If replacement is needed, refer to the “FILTER REPLACEMENT”

Type B, sub-section of this manual for complete instructions.

7. Place the new pre-fi lter into the pre-fi lter grid and secure into place with the 4 black knobs or 6

polypropylene clips.

8. Dispose of your PPE in accordance with your local guidelines for the substances that have been used

inside the hood.

MAINTENANCE