R410A 17.5 SEER Inverter Split System Technical Manual

2. Vacuum Dry and Leakage Checking

2.1 Vacuum Dry:

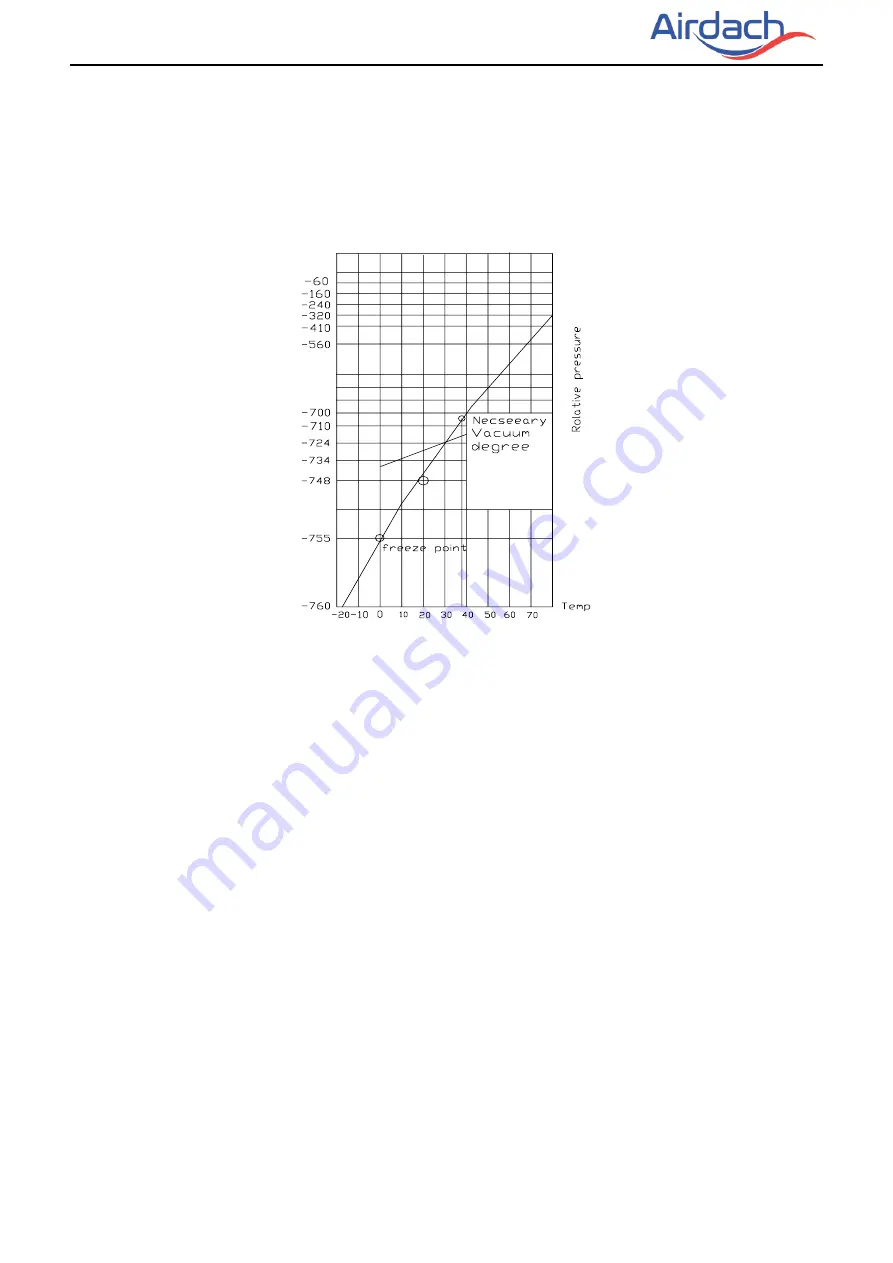

use vacuum pump to change the moisture (liquid) into steam (gas) in the pipe and

discharge it out of the pipe to make the pipe dry. Under one atmospheric pressure, the boiling point of

water (steam temperature) is 212°F. Use vacuum pump to make the pressure in the pipe near vacuum

state, the boiling point of water falls relatively. When it falls under outdoor temperature, the moisture in

the pipe will be vaporized.

2.2 Vacuum dry procedure

There are two methods of vacuum dry due to different construction environment: common vacuum dry,

special vacuum dry.

①

. Common vacuum dry procedure

⚫

Vacuum dry (for the first time)---connect the all-purpose detector to the inlet of liquid pipe and gas pipe,

and run the vacuum pump more than two hours (the vacuum pump should be below -755mmHg)

⚫

If the pump can’t achieve below -755mmHg after pumping 2 hours, moisture or leakage point will still

exist in the pipe. At this time, it should be pumped 1 hour more.

⚫

If the pump can’t achieve -755mmHg after pumping 3 hours, please check if there are some leakage

points.

⚫

Vacuum placement test: place 1 hour when it achieves -755mmHg, pass if the vacuum watch shows no

rising. If it rises, it shows there’s moisture or leakage point.

⚫

Vacuuming from liquid pipe and gas pipe at the same time.

⚫

Sketch map of common vacuum dry procedure.

Summary of Contents for ACTH2418VG1-D

Page 1: ...R410A Inverter Split System 17 5 SEER Technical Manual January 2021 Version A TM 18SS 01...

Page 4: ...R410A 17 5 SEER Inverter Split System Technical Manual 1 Nomenclature 1 1 Indoor unit...

Page 5: ...R410A 17 5 SEER Inverter Split System Technical Manual 1 2 Outdoor unit...

Page 22: ...R410A 17 5 SEER Inverter Split System Technical Manual 4 Service Space...