Summary of Contents for ACTH2418VG1-D

Page 1: ...R410A Inverter Split System 17 5 SEER Technical Manual January 2021 Version A TM 18SS 01...

Page 4: ...R410A 17 5 SEER Inverter Split System Technical Manual 1 Nomenclature 1 1 Indoor unit...

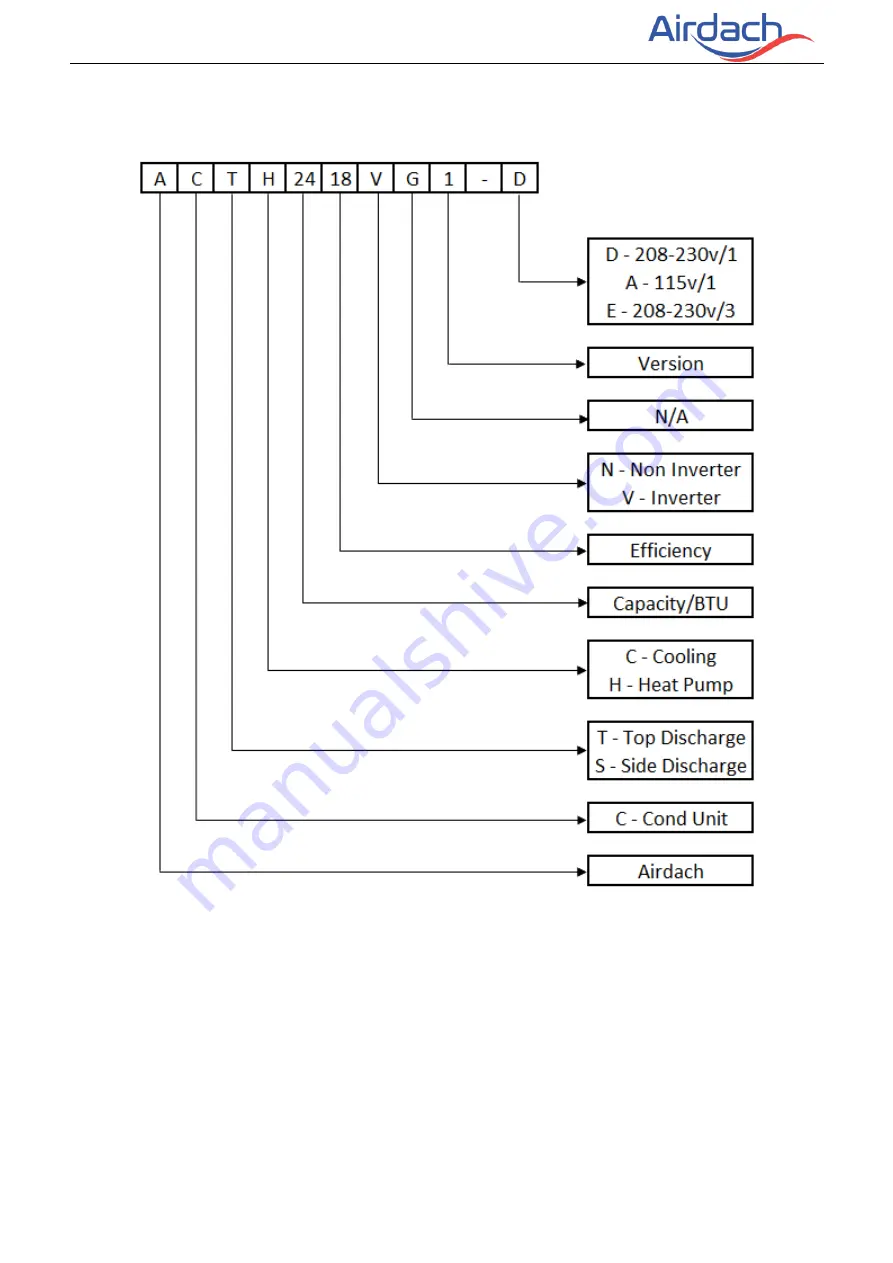

Page 5: ...R410A 17 5 SEER Inverter Split System Technical Manual 1 2 Outdoor unit...

Page 22: ...R410A 17 5 SEER Inverter Split System Technical Manual 4 Service Space...