Page 27

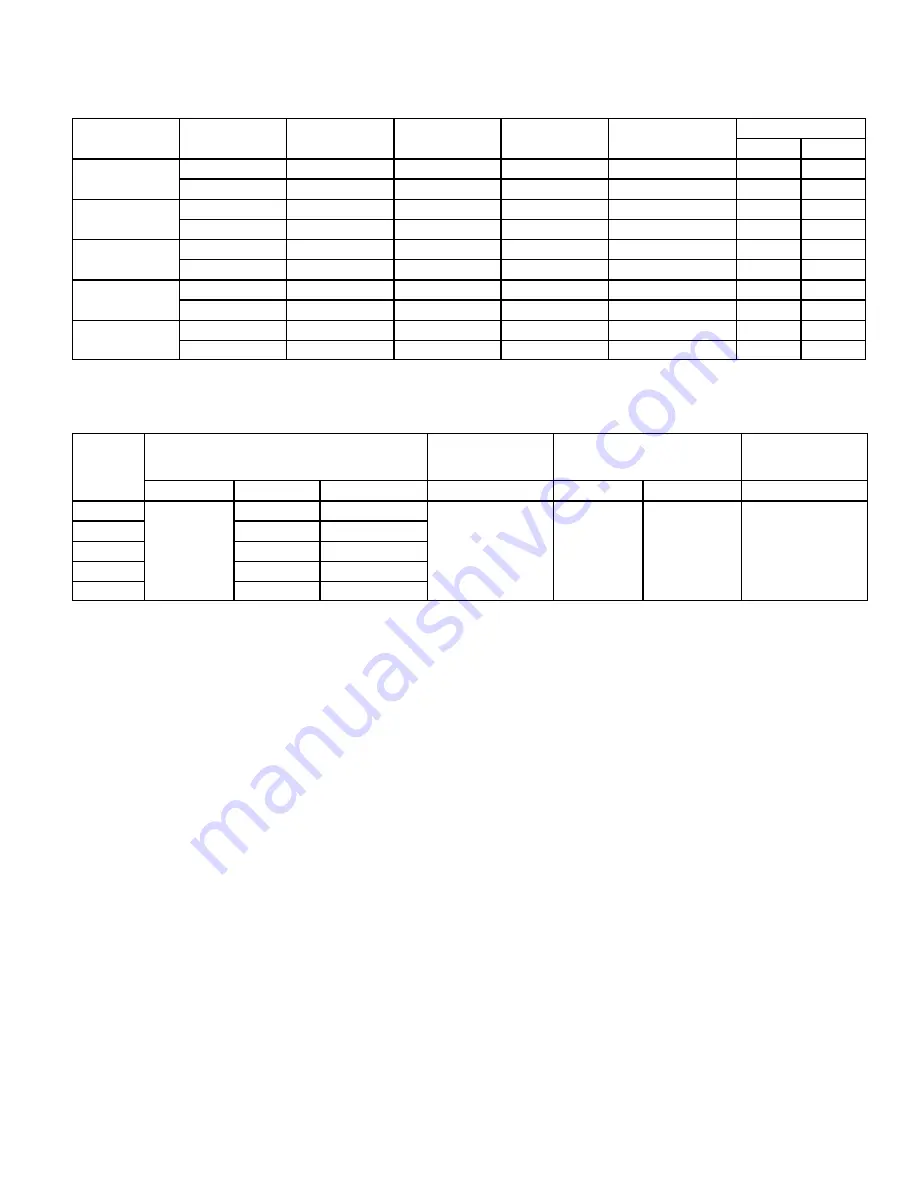

TABLE 9

Manifold Pressure Settings at all Altitudes

Model

Input Size

Gas

0-2000 ft

2105-4500 ft.

4501-7500 ft

7501 - 10,000 ft

Line Pressure in.wg.

Min

Max

045

Nat

3.5

3.2

3.0

3.5

4.5

13.0

LP/propane

10.5

10.0

10.0

3.5

11.0

13.0

070

Nat

3.5

3.2

2.8

3.5

4.5

13.0

LP/propane

10.0

10.0

10.0

3.5

11.0

13.0

090

Nat

3.5

3.2

2.7

3.5

4.5

13.0

LP/propane

10.0

10

9.6

3.5

11.0

13.0

110

Nat

3.5

3.5

3.0

3.5

4.5

13.0

LP/propane

10.0

10.0

9.6

3.5

11.0

13.0

135

Nat

3.5

3.5

2.9

3.5

4.5

13.0

LP/propane

10.0

10.0

9.6

3.5

11.0

13.0

TABLE 10

Pressure Switch and Gas Conversion Kits at all Altitudes

Model

Input Size

High Altitude Pressure Switch Kit

High Altitude

Natural Gas Burner

Orifice Kit

Natural Gas to LP/Propane

Burner Orifice Kit

LP/Propane to

Natural Gas Burner

Orifice Kit

0-4500 ft

4501-7500 ft

7501 - 10,000 ft

7501 - 10,000 ft

0 - 7500 ft

7501 - 10,000 ft

0 - 7500 ft

045

No Change

80W52

80W51

73W37

70W89

76W15

73W81

070

80W52

80W51

090

80W52

80W51

110

80W57

80W52

135

80W52

80W51

NOTE -

A natural to L.P. propane gas changeover kit is necessary to convert this unit. Refer to the changeover kit installation instruction for the conversion

procedure.

Other Unit Adjustments

Primary and Secondary Limits

The primary limit is located on the heating compartment

vestibule panel. The secondary limits (if equipped) are lo

cated in the blower compartment, attached to the back side

of the blower. These auto reset limits are factory-set and re

quire no adjustment.

Flame Rollout Switches

This manually reset switches are located on the top of the

burner box.

Pressure Switch

The pressure switch is located in the heating compartment

adjacent to the combustion air inducer. The switch checks

for proper combustion air inducer operation before allow

ing ignition trial. The switch is factory-set and requires no

adjustment.

Temperature Rise

After the furnace has been started, and supply and return

air temperatures have been allowed to stabilize, check the

temperature rise. If necessary, adjust the blower speed to

maintain the temperature rise within the range shown on

the unit nameplate. Increase the blower speed to decrease

the temperature. Decrease the blower speed to increase

the temperature rise. Failure to adjust the temperature rise

may cause erratic limit operation.

Fan Control

The fan-on time of 30 seconds is not adjustable. The heat

fan-off delay (amount of time that the blower operates after

the heat demand has been satisfied) may be adjusted by

changing the jumper position across the five pins on the in

tegrated control. The unit is shipped with a factory fan-off

delay setting of 120 seconds. The fan-off delay affects

comfort and is adjustable to satisfy individual applications.

Adjust the fan-off delay to achieve a supply air temperature

between 90° and 110°F at the moment that the blower is

de-energized. Longer off delay settings provide lower re

turn air temperatures; shorter settings provide higher re

turn air temperatures. See figure 32.