Page 10

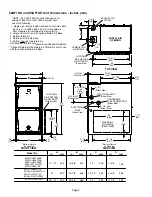

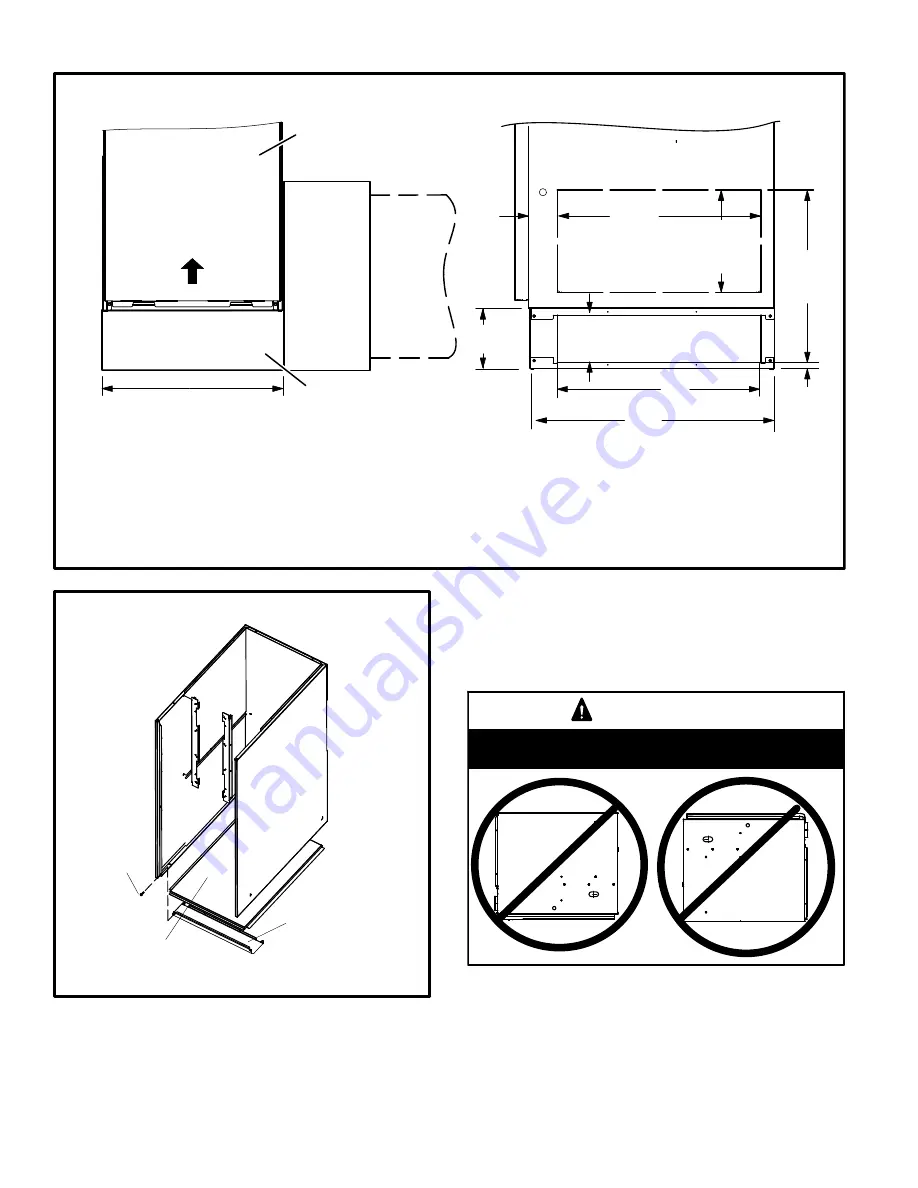

FIGURE 11

Optional Return Air Base

(Upflow Applications Only)

NOTE− Optional side return air filter kits are not for use with return air base.

1

Both the unit return air opening and the base return air opening must be covered by a single plenum or IAQ cabinet.

Minimum unit side return air opening dimensions for units requiring 1800 cfm of air and over (W x H): 23 x 11 in. (584 x 279 mm).

The opening can be cut as needed to accommodate plenum or IAQ cabinet while maintaining dimensions shown.

Side return air openings must be cut in the field. There are cutting guides stenciled on the cabinet for the side return air

opening. The size of the opening must not extend beyond the markings on the furnace cabinet.

2

To minimize pressure drop, the largest opening height possible (up to 14 inches) is preferred.

FRONT VIEW

1

Unit side return air

Opening

SIDE VIEW

3

−

1/4

(83)

1

23 (584)

Overall

(Maximum)

(584)

23

3/4

(19)

1

22

−

7/16

(570)

Overall

(Maximum)

SIDE RETURN

AIR OPENINGS

(Either Side)

5

−

5/8

(143)

1

Minimum

11 (279)

2

Maximum

14 (356)

(683)

26

−

7/8

7

−

1/4

(184)

FURNACE

FRONT

AIR FLOW

IF BASE

IS USED

WITHOUT

IAQ CABINET,

A SINGLE

RETURN AIR

PLENUM

MUST

COVER BOTH

UNIT AND

RETURN

AIR BASE

OPENINGS

INDOOR AIR

QUALITY

CABINET

(PCO, Filter

Cabinet, etc.)

AIR BASE

OPTIONAL

RETURN

17

−

1/2 (446) B Width (50W98)

21 (533) C Width (50W99)

24

−

1/2 (622) D Width (51W00)

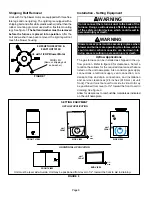

Removing the Bottom Panel

FIGURE 12

Screw

Bottom Panel

Bottom Cap

Removing the Bottom Panel

Remove the two screws that secure the bottom cap to the

furnace. Pivot the bottom cap down to release the bottom

panel. Once the bottom panel has been removed, reinstall

the bottom cap. See figure 12.

Horizontal Applications

FIGURE 13

Front

Back

WARNING

Do not install the furnace on its front or back.

See figure 13.

The 92AF1UH/95AF1UH furnace can be installed in hori-

zontal applications with either right− or left−hand air dis-

charge.

Refer to figure 14 for clearances in horizontal applications.