Page 8

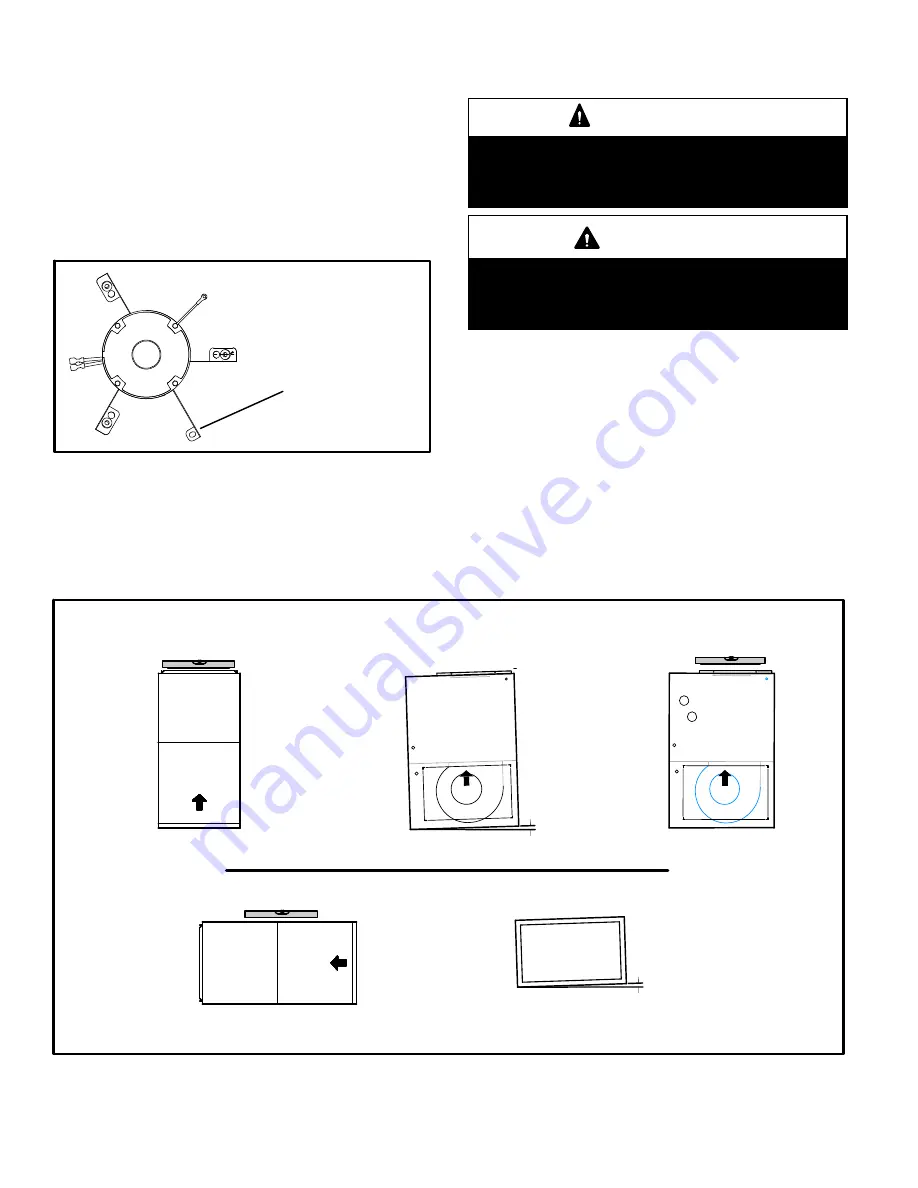

Shipping Bolt Removal

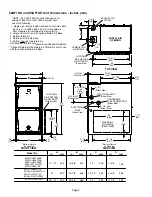

Units with 1/2 hp blower motor are equipped with three flex-

ible legs and one rigid leg. The rigid leg is equipped with a

shipping bolt and a flat white plastic washer (rather than the

rubber mounting grommet used with a flexible mounting

leg). See figure 7.

The bolt and washer must be removed

before the furnace is placed into operation.

After the

bolt and washer have been removed, the rigid leg will not

touch the blower housing.

FIGURE 7

RIGID LEG

(Remove shipping bolt

and washer)

Units with 1/2 HP Blower Motor

92/95AF1UH090P16C &

92AF1UH11016C

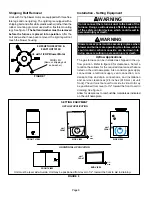

Installation − Setting Equipment

WARNING

Do not connect the return air duct to the back of the

furnace. Doing so will adversely affect the operation

of the safety control devices, which could result in

personal injury or death.

WARNING

Blower access panel must be securely in place when

blower and burners are operating. Gas fumes, which

could contain carbon monoxide, can be drawn into

living space resulting in personal injury or death.

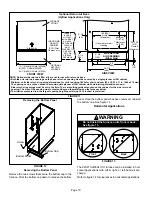

Upflow Applications

The gas furnace can be installed as shipped in the up-

flow position. Refer to figure 9 for clearances. Select a

location that allows for the required clearances that are

listed on the unit nameplate. Also consider gas supply

connections, electrical supply, vent connection, con-

densate trap and drain connections, and installation

and service clearances [24 inches (610 mm) at unit

front].

The unit must be level from side to side.

Unit may

be positioned from level to 1/2" toward the front to aid in

draining

.

See figure 8.

Allow for clearances to combustible materials as indicated

on the unit nameplate.

FIGURE 8

SETTING EQUIPMENT

UPFLOW APPLICATION

HORIZONTAL APPLICATION

FRONT VIEW

SIDE VIEW

FRONT VIEW

END VIEW

UNIT

FRONT

AIR FLOW

UNIT

FRONT

1/2"

max.

1/2"

max.

AIR FLOW

AIR FLOW

SIDE VIEW

UNIT

FRONT

Unit must be level side−to−side. Unit may be positioned from level to 1/2" toward the front to aid in draining.