Page 37

One line voltage “HUM” 1/4” spade terminal is pro

vided on the furnace integrated control. Any humidifier

rated up to one amp can be connected to this terminal

with the neutral leg of the circuit being connected to

one of the provided neutral terminals. See Figure 56

for control configuration. This terminal is energized in

the heatingmode whenever the combustion air inducer

is operating.

Install the room thermostat according to the instruc

tions provided with the thermostat. If the furnace is be

ing matched with a heat pump, refer to the instruction

packaged with the dual fuel thermostat.

Indoor Blower Speeds

When the thermostat is set to “FAN ON,” the indoor

blower will run continuously at approximately 50% of

the second stage cooling speed when there is no cool

ing or heating demand.

When the unit is running in the heating mode, the in

door blower will run on the heating speed designated

by the positions of DIP switches (A, B, C, D) of the

HEAT jumper. See figure 53.

When the unit is running in the cooling mode, the in

door blower will run on the cooling speed designated

by the positions of DIP switches (A, B, C, D) of the

COOL jumper. See figure 53.

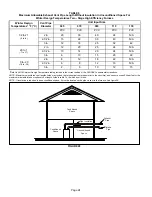

FIGURE 53

Adjust HEAT and COOL Taps on the

integrated Control

Generator Use - Voltage Requirements

The following requirements must be kept in mind when

specifying a generator for use with this equipment:

S

The furnace requires 120 volts (Range: 102 volts to

132 volts)

S

The furnace operates at 60 Hz + 5% (Range: 57 Hz to

63 Hz)

S

The furnace integrated control requires both correct

polarity and proper ground. Both polarity and proper

grounding should be checked before attempting to op

erate the furnace on either permanent or temporary

power

S

Generator should have a wave form distortion of less

than 5% THD (total harmonic distortion)

Electrical Wiring

The furnace must be grounded and wired in accordance

with local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

and/or CSA C22.1 Electrical Code (latest edition) if an ex

ternal electrical source is utilized

.

In all instances, other than wiring for the thermostat, the

wiring to be done and any replacement of wire shall con

form with the temperature limitation for Type T wire –635F

(355C) rise.

Connect a sufficiently sized wire with ground to the fur

nace's line voltage connections and ground wire. Refer to

the furnace rating plate for electrical characteristics to be

used in sizing field supply wiring and overcurrent protec

tion.

The line voltage supply should be routed through a readily

accessible disconnect located within sight of the furnace.

A junction box on the furnace side panel is provided for line

voltage connections. Refer to the furnace wiring diagram

for specific connection information.

Proper polarity of the supply connections (“HOT” and

“NEUTRAL”) must be observed to ensure that safety

controls provide the protection intended.

A connection to the unit's ground wire and actual earth

ground (typically a ground stake or buried steel pipe) must

be maintained for proper operation.

Thermostat Selection

Install a room thermostat according to the instructions fur

nished with it. Select a location on an inside wall that is not

subject to drafts, direct sunshine, or other heat sources.

The initial heat anticipator setting should be equal to the to

tal current draw of the control circuit. Low voltage thermo

stat connections are to be made to the integrated ignition/

blower control board as indicated on the wiring diagram.

Single Stage Thermostat Operation

The automatic heat staging option allows a single stage

thermostat to be used with two stage furnace models. To

activate this option, move the jumper pin (see Figure 54) to

desired setting (5 minutes or 10 minutes). The furnace will

start on 1st stage heat and stay at 1st stage heat for the

duration of the selected time before switching to 2nd stage

heat.