Chillers

DeltaChill™ Air Cooled and FreeCool

Introduction

5

Chiller Technical Manual 7267818 V1.13.0_01_2018

Specifiers Guide

9

Nomenclature 9

Introduction 9

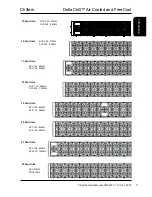

Range Layout

10

Unit Overview

12

Construction

14

Refrigeration

14

Compressor 14

Refrigeration Pipework Components

14

Electronic Expansion Valves (EEV)

15

Condenser Coils

16

Corrosion Resistant Coated Coils

16

Evaporator 16

Electrical

17

Phase Rotation Protection

18

Single Point Isolation

18

Electronic Soft Start

18

Control Panel Light

19

Mains Cable Entry

19

R410A Leak Detection

19

Condenser Fans

20

Condenser Fan and Motor - AC

20

Energy saving Electronically Commutated (EC) Fan Motor

20

High Airflow EC Fans

20

Waterside

21

Free Cooling Coil

21

Water Flow Switch

21

Water Connections

21

Waterside Options

23

Controls

24

General Description

24

Monitoring 25

Alarm Handling

26

Compressor Fast Start

26

Displays hours run of each pump.

27

Chiller Sequence Manager

27

Energy Manager

27

Mechanical

28

Lifting Lugs

28

Extended Discharge Air Plenum - Condenser Fan

28

Anti Vibration Mounts (Spring Type)

28

Anti Vibration Mounts (Pad Type)

28

Contents

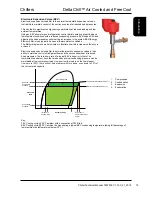

Environmental Considerations

Units with supply water temperatures below +5°C

●

Glycol is recommended when a supply water temperature of +5°C or below is required or when static water can

be exposed to freezing temperatures.

Units subject to ambient temperatures lower than 0°C

●

Glycol of an appropriate concentration (1) must be used within the system to ensure adequate freeze protection.

Please ensure that the concentration is capable of protection to at least 3K lower than ambient.

●

Water / glycol solution should be constantly circulated through all waterside pipework and coils to avoid static

water from freezing.

●

Ensure that pumps are started and running even during shut down periods, when the ambient is within 3K of the

solution freeze point (1) (i.e. if the solution freezes at 0°C, the pump must be operating at 3°C ambient).

●

Additional trace heating is provided for interconnecting pipework.

(1) Refer to your glycol supplier for details.

Environmental Policy

It is our policy to:

●

Take a proactive approach to resolve environmental issues and ensure compliance with regulatory requirements.

●

Train personnel in sound environmental practices.

●

Pursue opportunities to conserve resources, prevent pollution and eliminate waste.

●

Manufacture products in a responsible manner with minimum impact on the environment.

●

Reduce our use of chemicals and minimise their release to the environment.

●

Measure, control and verify environmental performance through internal and external audits.

●

Continually improve our environmental performance.

CE Directive

Airedale certify that the equipment detailed in this manual conforms with the following EC Directives:

Electromagnetic Compatibility Directive (EMC)

2014/30/EU

Machinery Directive (MD)

89/392/EEC version 2006/42/EC

Pressure Equipment Directive (PED)

2014/68/EU

Ecodesign

2009/125/EC

To comply with these directives appropriate national & harmonised standards have been applied. These are listed on the

Declaration of Conformity, supplied with each product.