SmartCool

TM

- D

Precision Air Conditioning

20

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

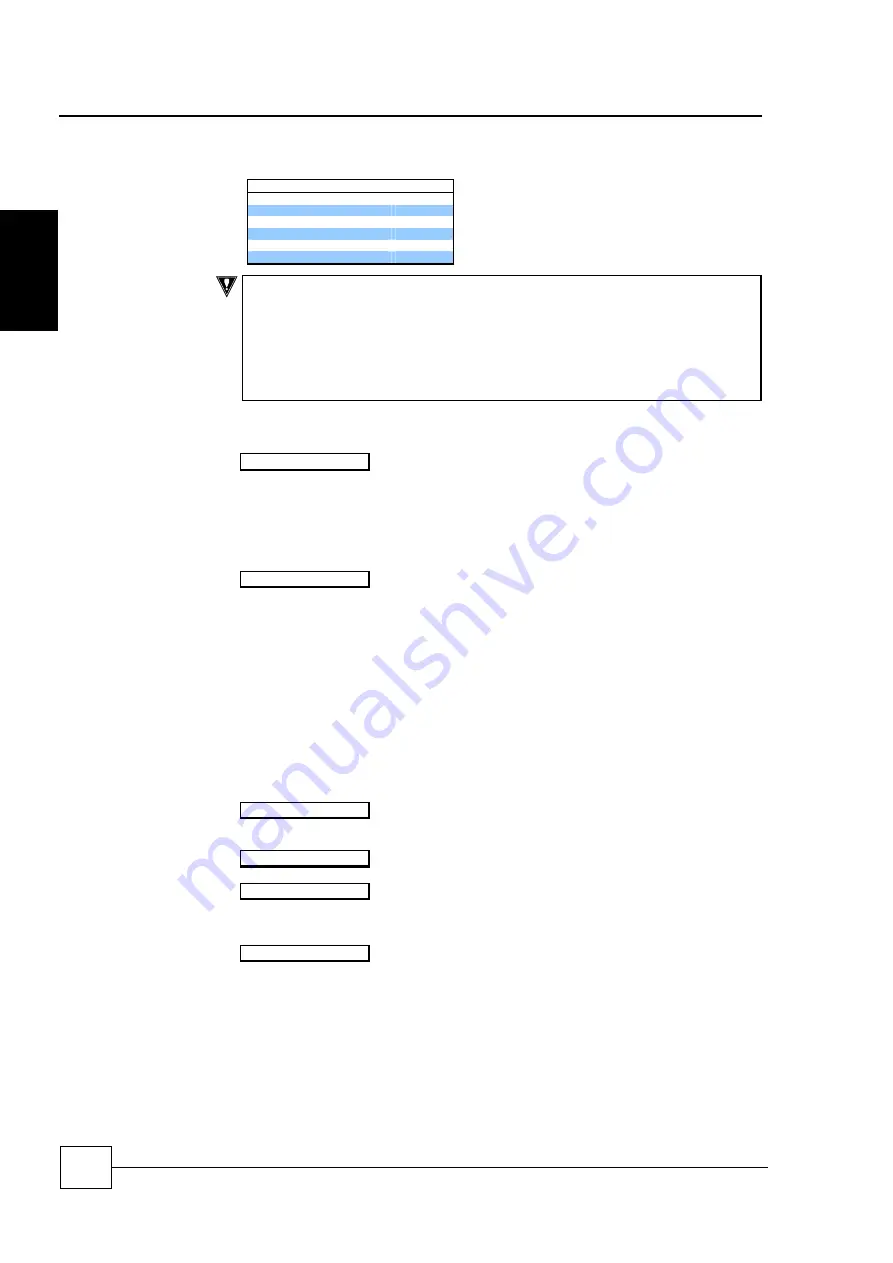

Liquid Line Refrigerant

Charge (kg/m)

The following table shows the refrigerant charge / metre for the liquid line, using R410A

and assuming a liquid line temperature of 40°C.

Liquid Line (m)

kg/m

3/8”

0.05

1/2”

0.09

5/8”

0.15

3/4”

0.21

7/8”

0.30

1 1/8”

0.53

IMPORTANT

The pipe sizes/refrigerant charges quoted are for guidance only. It is the responsibility of

the installing contractor/site engineer to check the pipe sizes/refrigerant charges are correct

for each system installation and application. Excess pressure drop on a system may require

additional refrigerant charges to ensure correct unit operation.

Split systems may require additional oil which should be added to the low side of

each compressor.

Design should be in accordance with accepted refrigeration practice to ensure good oil

return to the compressor(s) under all normal operating conditions.

Calculation of Liquid Line

Refrigerant Charge (kg)

The liquid line refrigerant charge can be calculated using the following equation:

LR = L x m

Where:

LR = Total Liquid Line Refrigerant charge (kg)

L

= Length of Interconnecting pipework (metres)

m

= Liquid Line Refrigerant charge / metre. Refer to

Liquid Line Refrigerant

Charge (kg/m), above.

Calculation of System

Refrigerant Charge (kg)

The system refrigerant charge can be calculated using the following equation:

SR = LR + IR + OR

Where:

SR = Total System Refrigerant charge (kg)

LR = Total Liquid Line Refrigerant charge. (As calculated from above)

IR

= Indoor Unit Refrigerant Charge.

OR = Outdoor Unit Refrigerant Charge.

Example

Indoor Unit Model Ref.

= SC19D055-X2X2-0

Outdoor Unit Model Ref.

= CR50 Condenser

Interconnecting Pipework

= 10 metres

Selecting The Liquid Line Size

From the

Refrigerant Pipe Sizing Guide

, the liquid line size given for pipework length of 10 metres

is:

Liquid Line Size

= 5/8”

Liquid Line Refrigerant

Charge

LR = L x m

Where:

L

= 10 metres

m

= 0.15 kg/m

LR = 10 x 0.15

Liquid Line Charge = 1.5 kg

System Refrigerant Charge

SR = LR + IR + OR

Where:

LR

= 1.5 kg. (As calculated from above)

IR

= 4.41 kg

OR = 4.9 kg

SR = 1.5 + 5.57 + 4.9

System Refrigerant Charge = 10.81kg / Circuit

Ins

ta

ll

a

ti

on