TURBOCHILL Chillers

Chillers

22

Installation Manual : 6703052 05/2008

Installation Data

GLYCOL DATA

For a given percentage of glycol in the system there are correction factors that need to

be applied, the following tables can be used as a guide.

CAUTION

The source data must be at 100% Water for the correction factors to be valid.

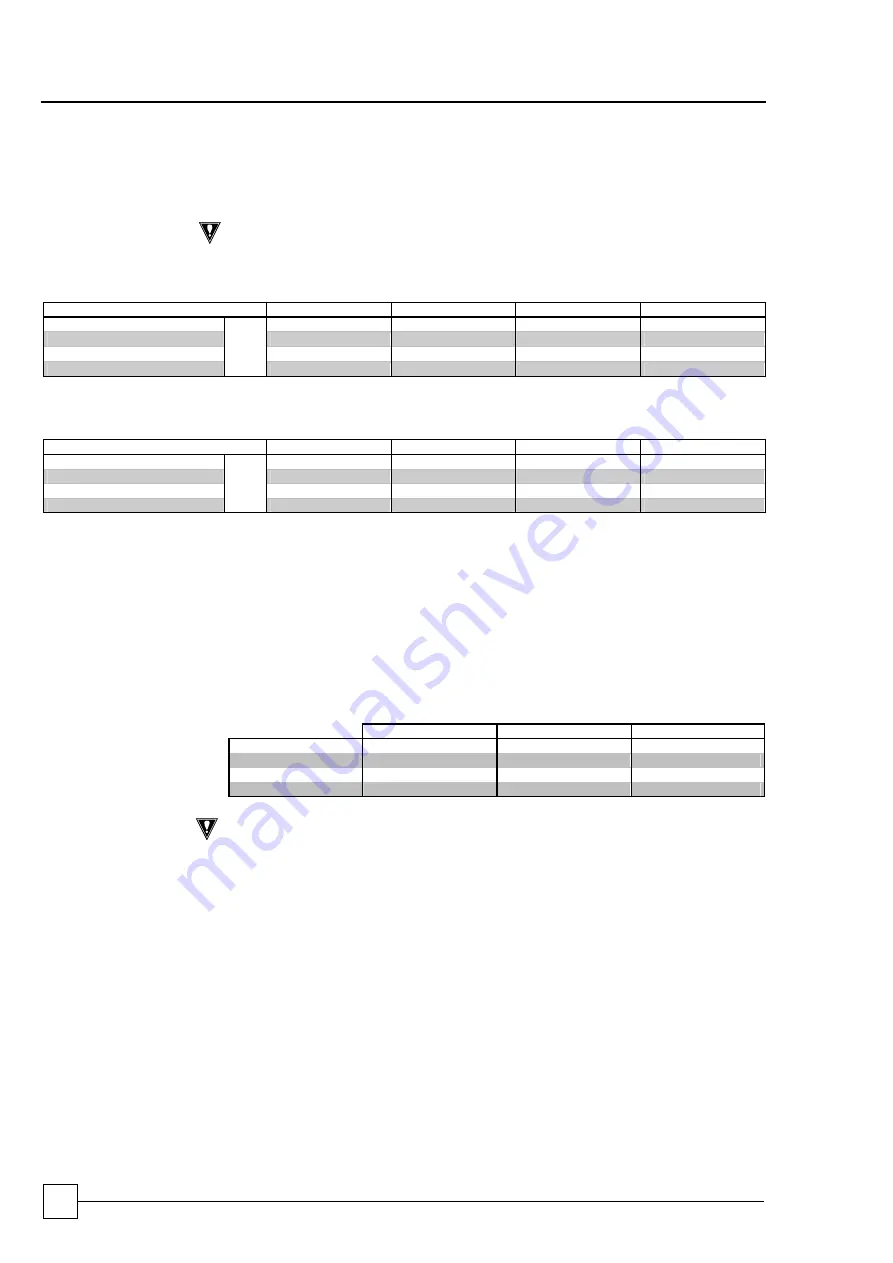

Ethylene Glycol Nominal Correction Factors

Glycol in System / Freezing Point ºC

10% / -4°C

20% / -9°C

30% / -15°C

40% / -23°C

Output (kW)

0.98

0.97

0.95

0.93

Compressor Input (kW)

0.99

0.98

0.96

0.95

Water Flow (l/s)

0.99

1.02

1.04

1.07

Pressure Drop (kPa)

x

1.05

1.20

1.38

1.57

Propylene Glycol Nominal Correction Factors

Glycol in System / Freezing Point ºC

10% / -2°C

20% / -6°C

30% / -12°C

40% / -20°C

Output (kW)

0.97

0.95

0.91

0.88

Compressor Input (kW)

0.99

0.98

0.96

0.95

Water Flow (l/s)

0.98

0.97

0.95

0.95

Pressure Drop (kPa)

x

1.08

1.17

1.31

1.45

Example:

At 100% Water:

Output

= 800 kW

Compressor Input

= 250.5 kW

Flow Rate

= 38.2

Pressure Drop

= 37.5 kPa

Ambient =

35°C

Inlet Fluid Temp.

= 7°C

Outlet Fluid Temp.

= 12°C (

5°C

Δ

T

)

To 20% Ethylene Glycol:

100% Water

Multiplier

Corrected Figures

Output (kW)

800.0

x 0.97

776.0 kW

Compressor Input (kW)

250.5

x 0.98

245.5 kW

Water Flow (l/s)

38.2

x 1.02

38.9 l/s

Pressure Drop (kPa)

37.5

x 1.20

45.0 kPa

Waste glycol needs to be handled responsibly, recycled or turned over to professional

personnel for correct disposal. Most anti-freeze manufacturers recommend that used anti-

freeze be collected and disposed according to Local Legislation. Waste glycol should NOT be

drained onto the ground, rainwater drainage system or natural waters.

If the glycol contains heavy metals or other contaminants from gas or oil, the level of hazard

posed by the glycol is increased and could be characterised as hazardous waste.

STEPS IF GLYCOL IS RELEASED/SPILLED

Small spill - soak up with absorbent material.

CAUTION

Large spill - contain spill and pump to suitable container for disposal.