Ultima Compact™

Chillers

19

Ultima Compact 30-150kW Technical Manual 9690553 V1.2.0_10_2019

Design Features & Information

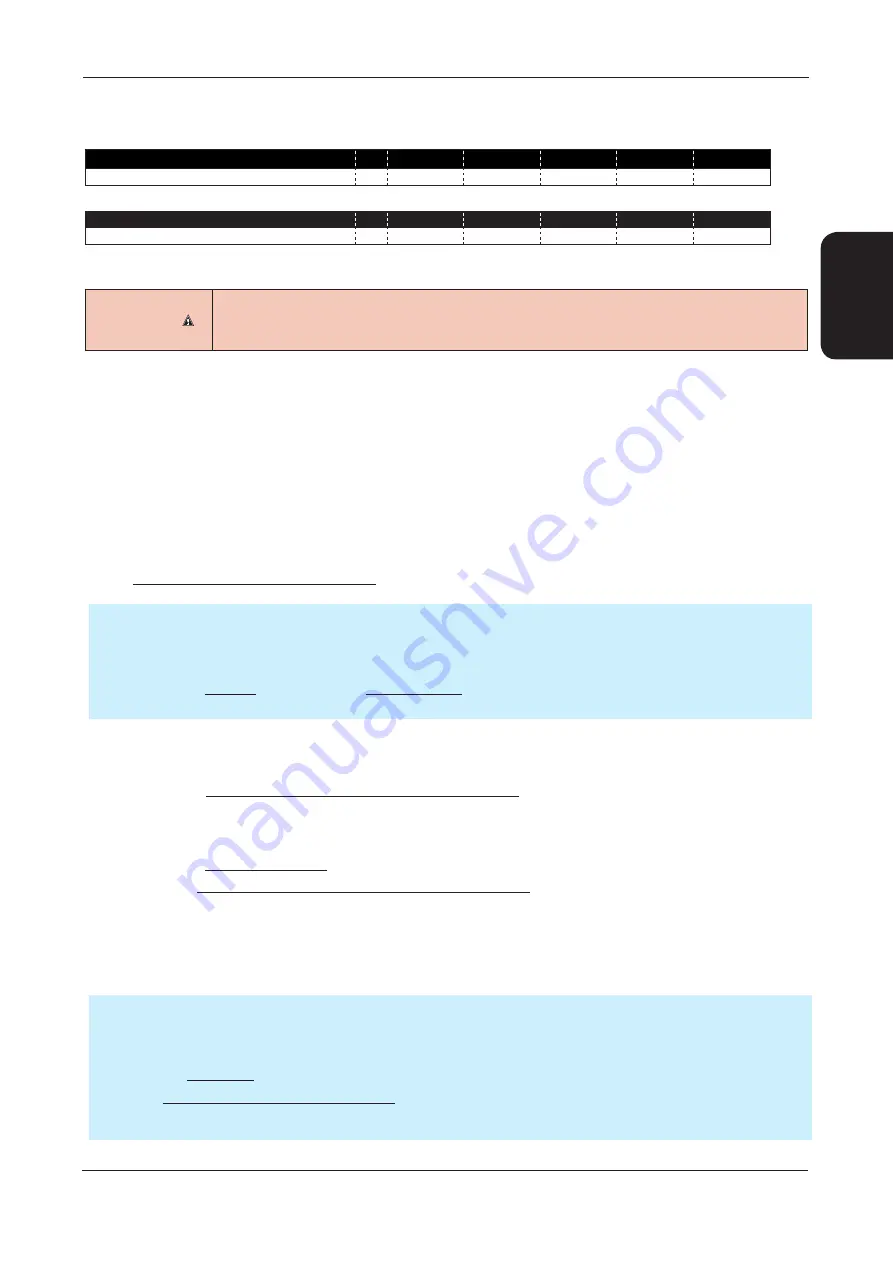

Specific Heat Capacity (SHC)

% Ethylene Glycol Concentration

0%

10%

20%

30%

40%

Specific Heat Capacity (kJ/kgK)

(1)

4.190

4.115

3.901

3.686

3.474

% Propylene Glycol Concentration

0%

10%

20%

30%

40%

Specific Heat Capacity (kJ/kgK)

(1)

4.190

4.139

4.033

3.903

3.749

(1) Data quoted for water/glycol solutions at a nominal temperature of 10°C.

Only use the SHC data when calculating fluid volume. Use figure for 0% concentration (100%

water). When calculating volumes of glycol solutions, refer to glycol data correction factors and

convert the water volume.

CAUTION

Minimum System Water Volume Calculations

METHOD 1

(Preferred Method)

Where the system permanent heat load is known, the minimum water volume in litres

V

min

is:

V

min

=

Water Flow Rate (litres/min) x

Minimum Compressor Run Time (min) x

Chiller Loading Factor (CLF)

Example: 150kW Cooling Duty at 35°C Ambient and 7/12°C Water

Minimum Turndown =

0.25 (25% : 4 Compressors)

150 x 3600

x 0.25 x 1.2

= 773.3 Litres

4.19 x 5

10

Where

V

min

is the minimum water volume in litres

Minimum Compressor Run Time is

6 minutes

CLF = Minimum Turndown x Cooling Duty x 1.2

Permanent Heat Load

METHOD 2

Where the system permanent heat load is unknown:

V

min

=

Cooling Duty x 3600

Cp x

Δt

x Min Turndown

x 1.2

Maximum number of Compressor starts(per hour)

V

min

=

Water Flow Rate (litres/hour) x Min. Turndown x 1.2

Maximum number of Compressor starts(per hour)

Please refer to Mechanical Data for information for Minimum Turndown for each model.

V

min

=

150 x 60

x 6

x

0.25 x 150 x 1.2

=

1546.5 Litres

4.19 x 5

75

Example: 150kW Cooling Duty at 35°C Ambient and 7/12°C Water

Permanent Heat Load:

75kW

Minimum Turndown =

0.25 (4 Compressors = 25%)

Ins

ta

lla

tio

n