þ

þ

þ

energy

bulbs

.co.uk

Mon-Fri:

8:30am - 6:30pm

| Sat & Sun:

11am - 5pm

08

00 0

43 8

97

8

or 0121 250 2180

Quick

O

rder Hotline

G

uaranteed Low Prices

Huge Stock Available

Airflow Stockist

1.10 Electrical connection

All work must be carried out with the equipment fully isolated from the power supply. The electrical connection

are to be carried out in accordance with the relevant wiring diagram and are only to be done by a certified elec-

trician. The electrical connection must be fully isolated from the supply up to the final assembly !

All relevant safety regulation, national standards and norms are to be adhered to. An appliance is required for cut off

from the supply with a minimum of 3 mm contact opening of each pole.

The rated voltage and frequency must correspond with the data on the type plate. The insertion of mains supply cable

is carried out via a cable grommet which is included in the delivery. Never lead cable over sharp edges. The equipment

corresponds to protection IPX5 (jet water-protected).

In addition, they correspond to the safety class II.

1.11 Overview of type.

QuietAir 100T

with timer overrun and interval operation

QuietAir 120T

with timer overrun and interval operation

1.12 Accessories (optional)

Wall switch 0-1-2

Ref:no. 71523101

2.0 Scope of delivery / packing unit

Leave the fan in its box until installation. Check that the fan is in good condition and has not been damaged in transit.

3.0 Preparation for wall or ceiling installation (surface mounted)

The assembly and start-up of the fan unit should be carried out first after finishing all other work and after the final

cleaning in order to avoid damage and contamination of the fan unit.

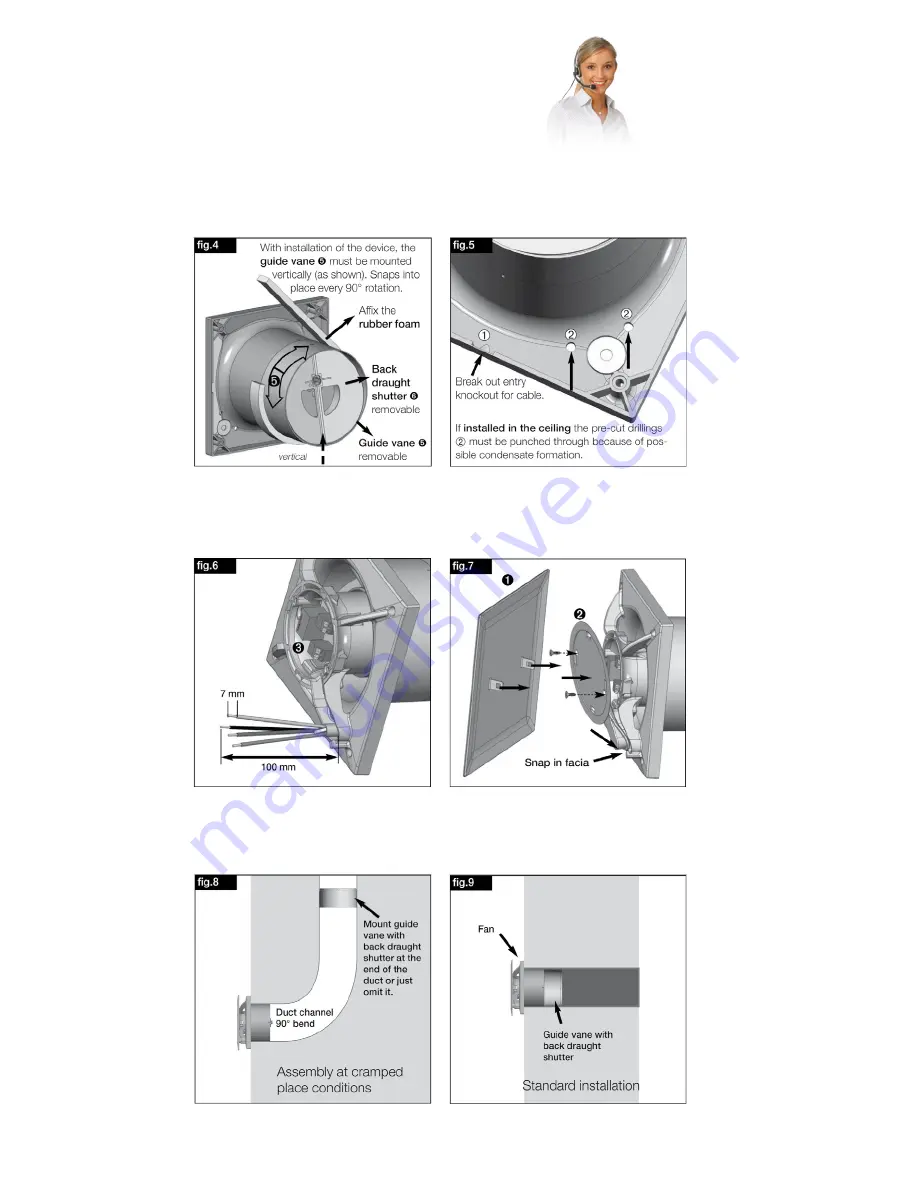

The position of the cable exit is variable (see fig.2/3).

3.1 Cable exit from the wall

- Distance to the duct centre depending on cable exit 58/68 mm with a variable position under the casing.

- For a simple assembly an exit is recommended as shown (turnable by 90° in each case).

The optimal position is 45° each if the cable exit is directly at the position of the cable grommet.

- Duct inside diameter QT100T =100mm / QT120T =120mm and distance to room corners: at least 90 mm

- Mounting hole radius QT100T = 58mm / QT120T = 68mm

3.2 Drill holes

- Set casing against the wall, mark the holes and drill. Fasten with at least 2 screws and plugs. For surface installation

the casing is provided with a side entry knockout (Fig.5, Pos.1) for the cable ! The mains supply cable is to be kept in

such a way that no ingress of moisture is made possible along the cable.

2

Installation and Operation Instructions

CHAPTER 2

SCOPE OF DELIVERY AND

ASSEMBLY

1.

Fascia

2.

Cover of control board

including 2 x fastening screws

3.

Electronic control board

4.

Casing

with impeller

5.

Guide vane

removable at reduced installation depth

6.

Removable back draught shutter

7.

Cable grommet

8.

Assembly kit

2 x screws with plugs for wall mounting

3

Installation and Operation Instructions

3.3 Wall or ceiling installation

3.4 Cable connections

1.

Pull cable through grommet, don’t cut open!

2.

Cut cable at least to length 180 mm and remove cable jacket at least 100 mm in length.

3.

Connect fan according to wiring diagram (see page 5).

4.

Run cable in the conduit. Ensure cable / grommett is sealed to maintain IP45.

WARNING

NOTE

1. Press cover of control board (2) on casing and

fasten with screws.

2. Snap in fascia. (1)

- Length of single conductor 100 mm

- Length of stripped insulation 7 mm

- Strip plastic-sheathed cable flush with conduit.

NOTE

fig.1

9041551_Model_QT_100_120T 30/06/2010 11:29 Page 1

energybulbs

.co.uk

energybulbs

.co.uk