þ

þ

þ

energy

bulbs

.co.uk

Mon-Fri:

8:30am - 6:30pm

| Sat & Sun:

11am - 5pm

08

00 0

43 8

97

8

or 0121 250 2180

Quick

O

rder Hotline

G

uaranteed Low Prices

Huge Stock Available

Airflow Stockist

4.0 Electrical connection

All work must be carried out with the equipment fully isolated from the power supply. The electrical connection

is to be carried out in accordance with the relevant wiring diagram and are only to be done by a certified

electrician. The fans may not be operated with transformer controllers.

All relevant safety regulation, national standards and norms are to be adhered to.

4.1 Electronic control board

The electronic control board allows the operation with 2 speeds (75/90 m

3

hr) for QT100T and (150/170 m

3

hr) for

QT120T. The control board is fitted into a splash-proof casing.

EMV regulation

Important indication for the electromagnetic compatibility

Interference resistance according to DIN EN 55014-2 depending upon impulse form and energy rate of 1000 V to

4000 V. With operation with fluorescent tubes, switch power supplies, electronically regulated halogen bulbs etc. these

values can be exceeded.

In this case additional suppression shielding activities are necessary (L -, C or RC elements, protection diodes,

resistors).

5.0 Cleaning and maintenance

- Before cleaning, ensure that the fan is isolated from the power supply.

- Prevent unintentional restart !

- Clean device only with a damp cloth.

- The device is maintenance-free.

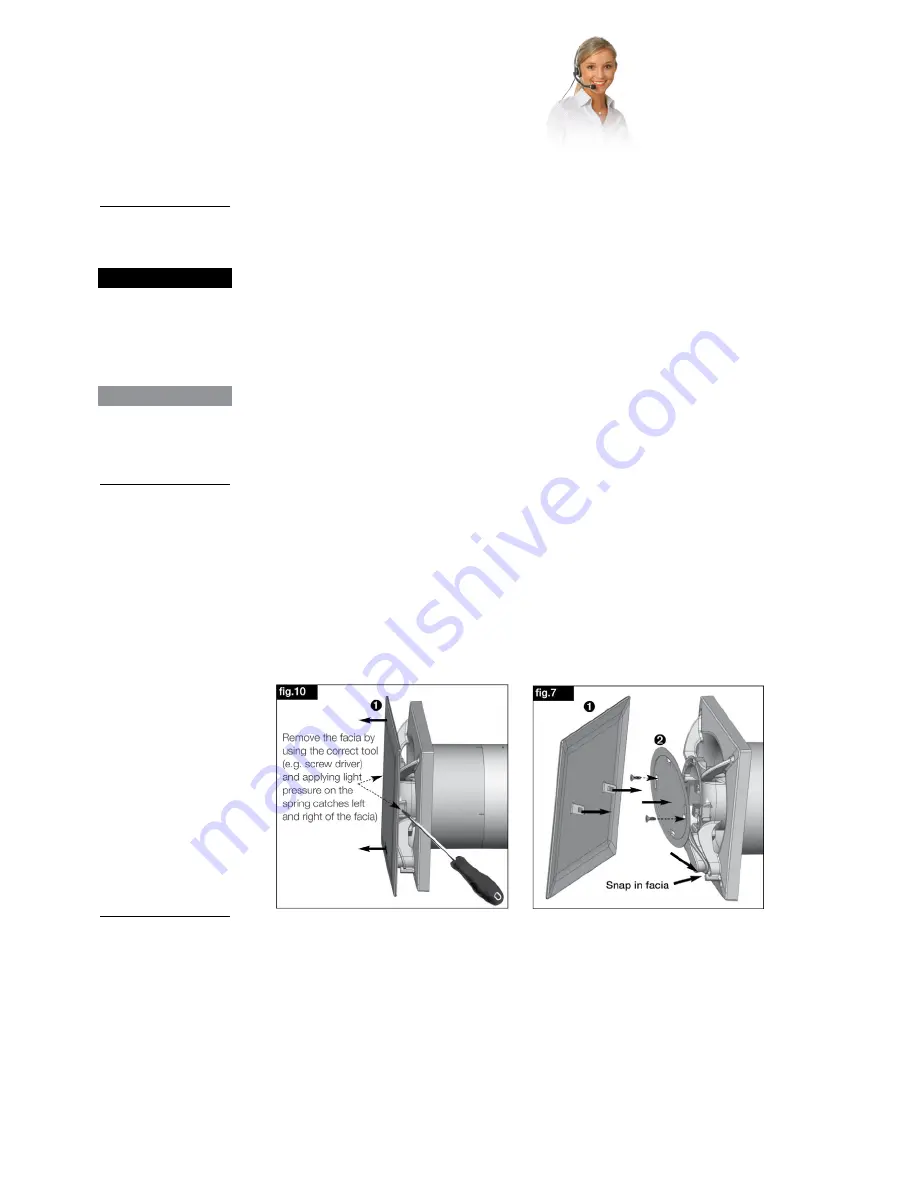

5.1 Dismantling of fascia

Procedure:

1. Isolate the device from the power supply and prevent unintentional restart!

2. Remove the fascia (1) by using the correct tool (e.g. screw driver) and applying light pressure on the spring catches

left and right of the fascia (Fig.10).

3. Unfasten the screws of the control board cover (2) (Fig.11).

6.0 Troubleshooting

- If the thermal protection trips this could be the result of dirt build-up, a hard running impeller and/or bearings.

Too high winding temperature through insufficient motor cooling, or too high air flow temperature could be the cause

of disturbance.

- Abnormal noises can mean worn out bearings.

- Vibrations can originate from an unbalanced or dirty impeller or due to the installation.

- Extreme performance reduction can occur if the fan must work against too high resistance of the ventilation system

or if there is a lack of sufficient supply air (causing also higher sound level).

5

Installation and Operation Instructions

4

Installation and Operation Instructions

WARNING

NOTE

CHAPTER 4

ELECTRICAL

CONNECTION

CHAPTER 5

CLEANING AND

MAINTENANCE

CHAPTER 6

TROUBLESHOOTING

5

Wiring diagram overview

QT100T - 75(90)m

3

/hr

QT120T - 150(170)m

3

/hr

Electrical connection:

- Terminal N / L:

The supply voltage of 230 V is connected permanently to

terminal N/L

- Terminal 1:

The time functions are activated via terminal 1.

The following functions are implemented:

1. Start delay (0 sec, 45 sec, 90 sec, 120 sec)

DIP-switch S1-2

(see wiring diagram SS-920.2)

After switching on terminal 1, the fan starts first after the adjusted

delayed time. Thus a room can be entered for a short time (via

two-pole switch) e.g. during combined on/off switching with the

light without the fan being started for operation. Factory setting

approx. 120 sec.

2. Operation with push-button switch

During start delay the fan can be switched on via terminal 1 with a

push-button switch at deactivated start delay (sampling pulse min.

0,5 sec.).

3. Run on time (6 min., 10 min., 15 min., 21 min.)

DIP-switch S3+4

(see wiring diagram SS-920.2)

After switching off terminal 1, the fan keeps running and switches

off after the adjusted time automatically. Factory setting approx.

15 min.

4. Interval operation (0 hrs., 8 hrs., 12 hrs., 24 hrs.)

DIP-switch S5+6

(see wiring diagram SS-920.2)

The fan can be put in adjustable time intervals into operation auto-

matically. After the adjusted run on time the fan switches off auto-

matically. The interval time starts after the last switch off process

on terminal 1 (time input), also with manual operation in the mean-

time (terminal 2). The manual operation does not have influence on

the interval operation. The turn-on time in the interval operation

corresponds to the adjusted run on time. Factory setting approx. 0

hrs.

In delivered condition the interval operation is deactivated. The DIP

switches have to be adjusted according to the table for a desired

interval.

5. Changing the factory setting

DIP-switch (see wiring diagram SS-920.2). Isolate the unit from the

mains electric supply !

- Terminal 2:

The continuous operation is activated via terminal 2 (see wiring

diagram SS-917). With activated time function, the manual stage

(terminal 2) is inactive.

Room lighting

In connection with the room lighting (terminal 1 or 2), a two-pole

switch must be used.

SS-931

M1/... N

SS-917

1

2

a) Zeitfunktion

b) manuell Ein

1 2

L

N

N

L

b)

a)

M1/... NC

Important: Wiring in parallel

Wiring in parallel of several fans is not permitted.

- Jumper

Depending on the jumper setting, the fan QT100T runs with 75 or 90 m³/h or rather the fan

QT120T with 150 or 170 m³/h.

Jumper 1 (see wiring diagram SS-931)

QT100T / QT 120T

Position A – Factory setting

Kl. 1 = 75 m³/h / 150 m³/h, activation via time function

Kl.2 = 90 m³/h / 170 m³/h, manual on

Position B

Kl.1 = 90 m³/h / 170 m³/h, activation via time function

Kl.2 = 75 m³/h / 150 m³/h, manual on

Operation test – Test mode:

When applying the supply voltage the fan is in the test mode for 1 minute.

(Requirement: Factory setting of DIP-switch, see wiring diagram SS-920.2)

In this case the delayed start and the overrun function is deactivated within the first

minute, or for a switching cycle.

Internal functional principle / Jumper position

Connection client

WARNING

S

SS-920.2

Adjustment of DIP-switchs

a) time function

b) manual on

M1~

L

N

1

2

Kl.1=

Jumper 1

A / B

A

B

Zeit-Eingang

Manueller-Eingang

1 2

L

N

Kl.2=

Kl.1=

Kl.2=

time function/- input

manual input

S1

1 2

L

N

QT ... T

Einschaltv erzöger ung

Dela yed star t

Démarrage tempor isé

Nachlauf /

Einschaltz eit

Intervallzeit,

Einschaltdauer =

Nachlauf ze it

1

2

3

4

55

off

on

off

off

on

off

off

on

on

on

off

off

on

off

off

on

on

on

0 sec

45 sec

6 min

10 min

15 min

21 min

0 Std

8 Std

12 Std

24 Std

DIP-Schalter

/

Switch / Commutateur

Run on time /

Running time

Temporisation /

Durée de f onctionnement

Interval time

Running time = Run on time

Durée inter valle

Durée de f onctionnement =

Temporisation

off

on

1 2 3 4 5 6

6

off

on

90 sec

120 sec

off

off

on

on

9041551_Model_QT_100_120T 30/06/2010 11:29 Page 3

energybulbs

.co.uk

energybulbs

.co.uk