4

Unit is Operating and Blows Evaporator Air, but the Supply Air is not Colder than

Manufacturer’s Warranty – U.S. and Canada only .................................... 51

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

•

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•

Consult the dealer or an experienced radio/TV technician for help.

RSS GEN (English)

This device contains licence-exempt transmitter(s)/receiver(s) that comply with Innovation, Science and Economic

Development Canada’s licence-exempt RSS(s). Operation is subject to the following two conditions:

1.

This device may not cause interference.

2.

This device must accept any interference, including interference that may cause undesired

operation of the device.

RSS GEN (French)

L’émetteur/récepteur exempt de licence contenu dans le présent appareil est conforme aux CNR d’Innovation,

Sciences et Développement économique Canada applicables aux appareils radio exempts de licence. L’exploitation

est autorisée aux deux conditions suivantes :

1.

L’appareil ne doit pas produire de brouillage;

2.

L’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible

d’en compromettre le fonctionnement.

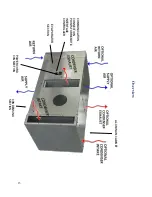

Summary of Contents for WINE GUARDIAN CAB018

Page 14: ...14 CAB018 Cabinet Unit...

Page 15: ...15 CAB018 and CAB25...