www.airkinglimited.com

6728076 Rev. Q 3/22

2 of 12

INSTALLATION INSTRUCTIONS

CAUTION:

MAKE SURE POWER IS SWITCHED

OFF AT SERVICE PANEL BEFORE STARTING INSTALLATION.

SECTION 1

Preparing the Fan

1.

Unpack fan from the carton and confirm that all pieces are present. In addition to the fan

you should have:

2 - Collar Assembly (attached)

2 - Mounting Brackets (attached)

1 - Controller (attached) (QFAM Only) 1 - Instruction/Safety Sheet

2. Choose the location for your fan. To ensure the best air and sound performance, it is

recommended that the length of ducting and the number of elbows be kept to a minimum,

the radius of each elbow be as large as possible for the installation, and that insulated hard

ducting be used. This fan will require at least 12” of clearance in the ceiling or wall. The fan

mounts using the provided mounting brackets or can be surface mounted to a wall or ceiling.

NOTE:

The fan must be installed into a location that can be easily accessed once installed.

3.

No additional vibration deadening materials are needed for this fan.

SECTION 2

Mounting the Fan

1.

Confirm the fan is positioned so the air flow is in the correct direction.

2a.

Surface Mounting:

Locate at least one stud or joist. Place the fan in position so that the

mounting bracket is centered on the stud or joist and make the location for the four (4)

holes. Remove the fan and install properly rated wall/ceiling anchors for the holes that do

not go directly into a joist or stud. Position fan in place and secure with screws (not

included)

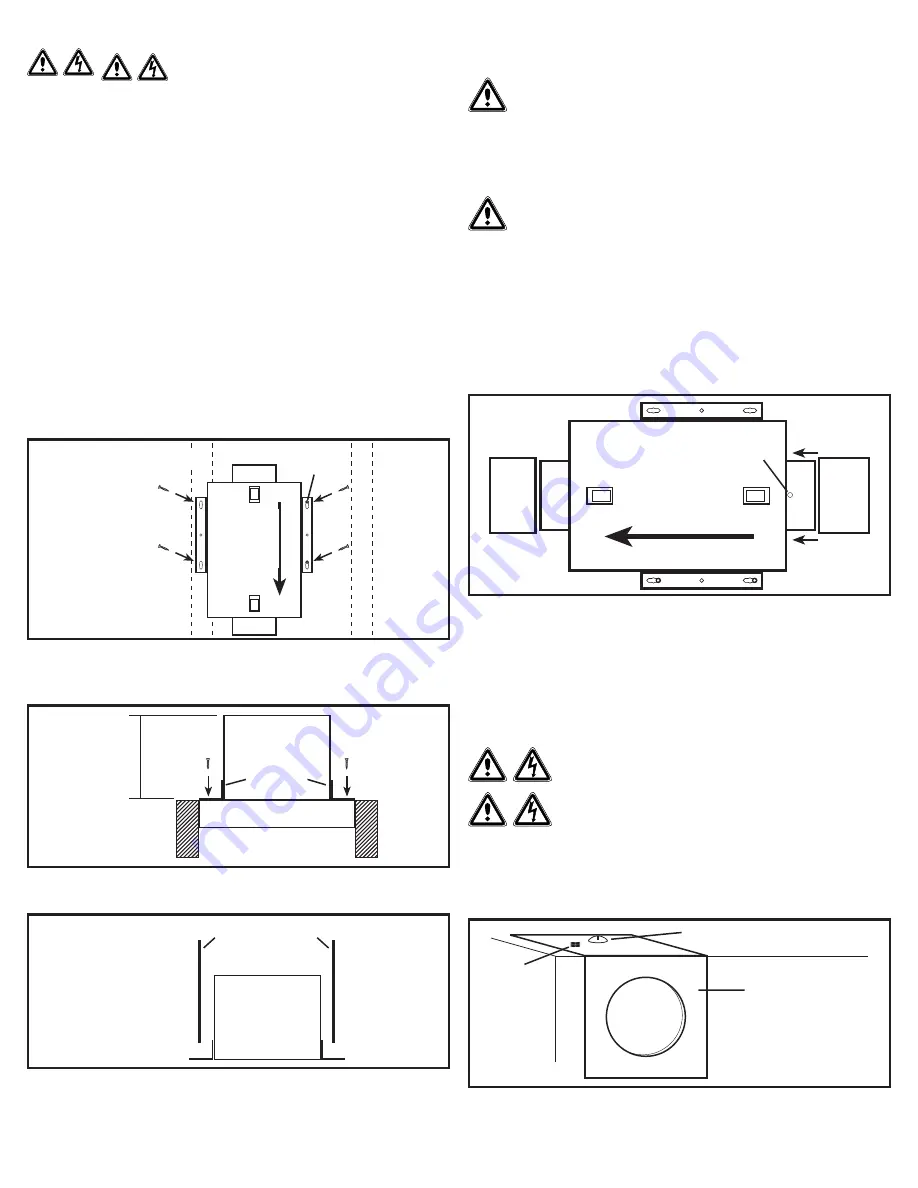

(Figure 1).

2b.

Mounting to a Joist:

Install two - 2 x 4 headers (not included) between the joists. Position

the fan housing on top of the headers and secure the mounting brackets with screws (not

included) to the header

(Figure 2)

.

2c.

Hanging Bar Mounting:

Lift unit up onto the threaded rods and secure in place using

appropriate hardware (not included)

(Figure 3).

Figure 1

Screws

Stud/Joist

Anchor

Air Flo

w

Figure 2

Joist

2 x 4 Header

Bracket

12"

Figure 3

Bracket

Housing

Threaded Rod

SECTION 3

Ducting

NOTE: 6” OR LARGER RIGID DUCT IS RECOMMENDED FOR BEST PERFORMANCE.

CAUTION:

ALL DUCTING MUST COMPLY WITH LOCAL AND NATIONAL

BUILDING CODES.

NOTE:

The ducting from this fan to the outside of the building has a strong effect on the air

flow, noise and energy use of the fan. Use the shortest, straightest duct routing possible for

best performance, and avoid installing the fan with smaller ducts than recommended. Insulation

around the ducts can reduce energy loss and inhibit mold growth. Fans installed with existing

ducts may not achieve their rated air flow.

WARNING:

MAKE SURE THE FRESH AIR INTAKE PORT COMPLIES WITH

ALL LOCAL AND NATIONAL CODES AND IS LOCATED AT LEAST 6 FEET AWAY

FROM SOURCES OF CONTAMINATION SUCH AS BUT NOT LIMITED TO: DRYER,

FURNACE OR CENTRAL VACUUM EXHAUSTS, GAS APPLIANCES SUCH AS BBQ GRILLS,

GARBAGE BINS OR OTHER EXHAUST PORTS.

NOTE:

To ensure quiet operation of in-line and remote fans, each fan shall be installed using sound

attenuation techniques appropriate for the installation. This can typically be achieved by installing

insulated flexible ducting between the exhaust or supply grille(s) and the fan.

1.

Connect the ducting to the fan’s duct collar

(Figure 4).

Seal ducting to housing with

appropriately rated tape. Use screws or suitable clamps to secure in place. Make sure the

fresh air intake is connected to a properly installed intake port that is a suitable weather

hood with insect screen to protect air intake. It is recommended that low restriction

termination fittings be used.

2.

Ensure duct joints and exterior penetrations are sealed with caulk or other similar material

to create an air-tight path to minimize building heat loss or gain and to reduce the potential

for condensation. Place/wrap insulation around duct and/or fan in order to minimize possible

condensation buildup within the duct, as well as building heat loss or gain.

NOTE:

At the base of the duct adapter, there is a small diameter test port hole covered with a

plastic cap. Make sure the test port is not covered up with the ducting so that it can be accessed

for pitot tube testing. To access the port, remove the port cover and insert tube.

SECTION 4

Wiring

CAUTION:

MAKE SURE POWER IS SWITCHED OFF AT SERVICE

PANEL BEFORE STARTING INSTALLATION.

CAUTION:

ALL ELECTRICAL CONNECTIONS MUST BE MADE

IN ACCORDANCE WITH LOCAL CODES, ORDINANCES, OR NATIONAL

ELECTRICAL CODE. IF YOU ARE UNFAMILIAR WITH METHODS OF

INSTALLING ELECTRICAL WIRING, SECURE THE SERVICES OF A

QUALIFIED ELECTRICIAN.

NOTE:

This unit includes a side access panel for wiring that does not require the removal of the

fan’s blower assembly.

1. Remove the wire compartment cover screw and place cover in a secure place

(Figure 5).

Figure 4

Air Flow

Intake Ducting

Outlet Ducting

Test Port

Figure 5

Screw

Wire

Compartment

Cover

Ground

Screw