Operation

8

3A1182G

Fill the Packing Nut/Wet Cup

1. Fill the Packing Nut/Wet Cup with 5 drops of Air-

lessco Throat Seal Oil (TSO).

Flush the Sprayer

1. Flush the sprayer. See

Flushing Procedure

on

page

Prime and Flush Storage Fluid

Before beginning a new spraying project you need to

prime the sprayer and flush the storage fluid out of the

sprayer.

Oil- or Water-based Materials

•

When changing from water-based

material to oil

based material, flush with soapy water and then

mineral spirits solvent (also called white spirit).

•

When changing from oil based material to water

base material, flush with mineral spirits solvent (also

called white spirit), followed by soapy water, then a

clean water flush.

•

When flushing with solvents, ground pail and gun.

•

Flush before changing colors, before fluid can dry in

the equipment, at the end of the day, before storing,

and before repairing equipment.

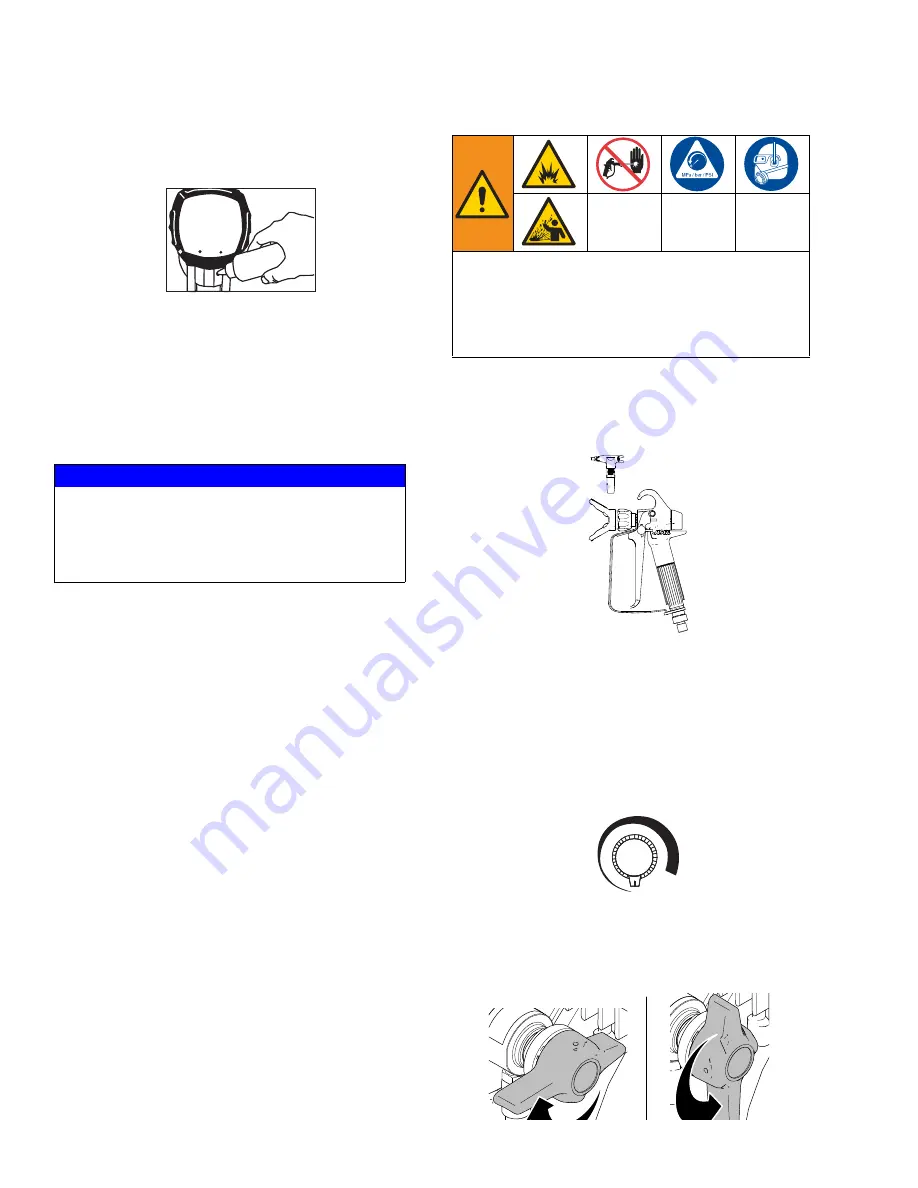

Flushing

1. Make sure the gun trigger lock in engaged and there

is no spray tip in the gun. Refer to the separate

instruction manual provided with gun for safety fea-

tures and how to engage the trigger lock.

2. Pour enough clean, compatible solvent into a large,

empty metal pail to fill the pump and hoses.

3. Place the suction tube into the pail or place the pail

under the pump.

4. Turn Pressure Control Knob to low.

5. Open the prime/pressure relief valve to the open -

“Priming Position”. This will allow an easy start.

NOTICE

The equipment was tested with lightweight oil, which

is left in the fluid passages to protect parts. To avoid

contaminating your fluid with oil, flush the equipment

with a compatible solvent before using the equipment

for the first time.

M

M

•

To reduce the risk of static sparking, which can

cause fire or explosion, always hold a metal part

of the gun firmly against the metal pail when flush-

ing. This also reduces splashing.

•

To reduce risk of injection, always remove the

spray tip before flushing.

ti16028a

ti16048a

HIGH PRESSURE

Closed (Pressure)

Open

(Priming and Pressure Relief)

ti14791a

ti16049a