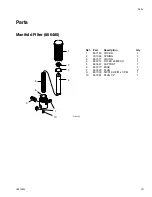

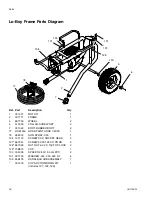

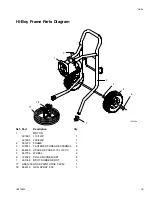

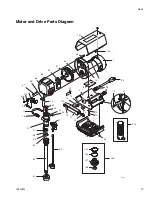

Parts

3A1182G

33

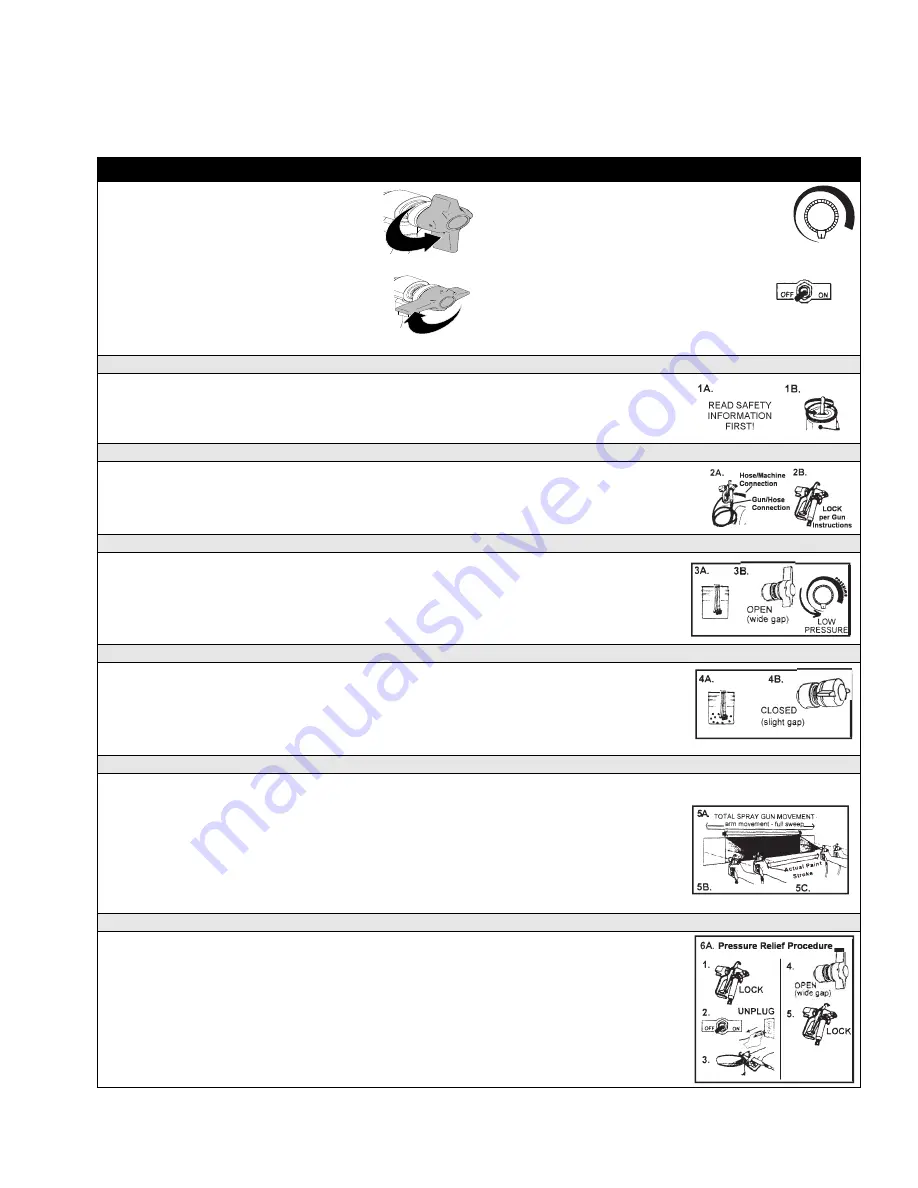

EZ Series Electric Paint Sprayer Quick Reference Guide

Operation

Prime Pressure Relief Valve (Prime-PR Valve)

Used to relieve pressure from gun, hose and tip

and to prime the unit when in OPEN position. (It is

in open position when there is a wider gap between

handle and body).

Pressure Control Knob

Used to adjust pressure only. DOES NOT relieve

pressure from gun and system. Turn clockwise to

increase pressure, counterclockwise to decrease

pressure.

When in the CLOSED position, there is only a very

slight gap between handle and body. When the

prime/pressure relief valve is closed the system is

pressurized.

ON/OFF Toggle Switch

Turns the unit ON and OFF

STEP 1

1A.

Read safety rules! Read & understand all warnings & safety rules before operating equipment. Know

how to lock the gun trigger lock before operating the equipment.

1B.

Stir paint and if necessary strain paint using a paint strainer bag to remove lumps.

STEP 2

2A.

Check gun/hose connections to make sure they are tight.

2B.

Lock gun trigger lock (Airlessco gun shown).

Plug into 3 pronged grounded electrical outlet. Extension cord must be 3 wire, 12 gauge. Do not coil

cord.

STEP 3

3A.

Put pump suction tube into bucket of paint.

3B.

Turn the Prime-Pressure Relief Valve to open position (wide gap between handle and body).

Turn toggle switch ON, and adjust to low pressure on the pressure control knob. The unit will now self

prime.

STEP 4

4A.

Wait about one minute until fluid comes out of the return tube (smaller diameter tube).

4B.

Turn the Prime-Pressure Relief Valve to closed position. (slight gap between handle and body)

The

unit is now pressurized.

STEP 5

Leave the Prime-Pressure Relief Valve fully closed and very carefully unlock the gun trigger safety lock.

5A.

Aim the gun 12” from test surface cardboard and spray out the storage solution. Turn the pressure

control knob clockwise to increase pressure. Increase the pressure enough to atomize the paint and

give a full pattern. Use the lowest pressure possible.

5B.

Always keep the gun perpendicular to the surface. Move the gun at a steady rate. It is important to

“trigger” the gun after gun movement has begun and release trigger before gun movement ends.

5C.

Overlap half the width of each paint stroke.

STEP

6

6A.

Release pressure when you stop spraying and before servicing gun or machine or before changing or

cleaning gun tip by:

1.

Lock the gun trigger lock.

2.

Turn toggle switch to OFF position and

unplug from electrical outlet.

3.

Release gun trigger lock and trigger

gun to relieve residual pressure

4.

Turn Prime/PR Valve to open position.

5.

Relock gun trigger lock

6B.

Submerge gun in water (if using latex) or thinner (oil-base) to prevent from drying in the gun nozzle.

ti14791a

ti16048a

ti14790a

ti16067a

ti16068a

ti16069a

ti16070a

ti16071a

ti16072a

ti16073a

ti16066a