30

the cooling system, producing operating noise. Even

when the compressor cuts out, noises caused by

changes

in

temperature

and

pressure

are

unavoidable. Operating noise will be most audible

immediately after the compressor cuts in. It

becomes quieter as the operating period continues.

The following noises are normal and occur from time

to time:

- Gurgling sound, caused by the refrigerant flowing

through the appliance’s coils,

- Humming noise made by the motor compressor.

This noise can get louder for brief periods when

the motor is switching on.

- Cracking/popping sounds, resulting from the

materials contraction and expansion due to

temperature variations,

- Fan operating sound, to circulate the air within

the wine cabinet.

Unusual noise is normally the result of improper

installation. Under no circumstances must tubing

come into contact with a wall, other furniture or with

other tubing.

Where the unit is installed in open-plan kitchen or in

partition walls, the level of operating noise will be

heard more acutely. However, this is due to the

surrounding architecture and not to the unit.

An individua

l’s perception of noise is directly linked

to the environment in which the unit is located, as

well the specific type of models. Our appliances are

in line with international standards for such

appliance and in line with the latest technical

developments. But please remember that the noise

of the compressor and the coolant circulating in the

system is unavoidable.

DEFROSTING

/

HYGROMETRY

/

VENTILATION

Your unit is designed with an automatic defrost

system. During the

“Off-cycle” the evaporator behind

the rear wall of the unit defrosts automatically. The

condensate collects in the drain trough behind the

rear wall of the unit, and part of it flows through the

drainage hole into the drip tray by/above the

compressor. The heat is transferred from the

discharge pipe or compressor and evaporates any

condensation that has collected in the tray. Part of

the remaining water is collected within the unit for

humidity purposes.

This system enables the creation of the correct

humidity level inside your unit required by the

natural cork to maintain a long lasting seal.

The appliance is not totally sealed: fresh air

admission is permitted through the drainpipe. Air is

circulated through the unit by means of a fan / fans

and the hollow shelves.

NOTE:

Frost may be accumulated on the

evaporator if the unit is repeatedly opened in a high

heat or high humidity location. If this frost pattern

does not clear within 24 hours, your unit will require

manual defrosting.

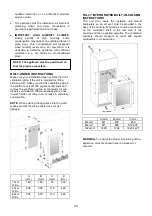

BOTTLE STORAGE

Many bottles may differ in size and dimensions. As

such the actual number of bottles you may be able

to store may vary.

Bottle capacities are approximate maximums when

storing traditional Bordeaux 750 ML bottles and

include bulk storage.

You may load your wine bottles in single row or by

stacking while taking note of the following: if you do

not have enough bottles to fill your wine cellar, it is

better to distribute the load throughout the wine

cellar so as to avoid “all on top” or “all below” type

loads.

-

Do remove or relocate adjustable wooden

shelves to accommodate larger type of bottles

or increase the capacity of the cellar by

stacking the bottles up when necessary. (See

removing shelves)

-

Keep small gaps between the walls and the

bottles to allow air circulation. Like an

underground cellar air circulation is important

to

prevent

mould

and

for

a

better

homogeneous temperature within the cellar.

-

Do not over load your wine cellar to facilitate

air circulation.

-

Avoid obstructing the internal fans (located

inside on the back panel of the wine cellar).

-

Do not try to slide the shelves outwards

beyond the fixed position to prevent the bottles

from falling.

-

Do not pull out more than one loaded shelf at

a time as this may cause the wine cellar to tilt

forward if not properly installed.

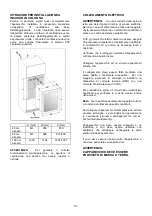

WINE SERVING TEMPERATURE CHART

All wines mature at the same temperature, which is

a constant temperature set between 11ºC to 14ºC.