2. Operation

2

-

11

2.6.9 Check V-Belt Tension

Too tight belt tension could damage shaft and shorten bearing life. Too loose belt tension may result in

damaging belt earlier and machine components due to overheat.

Follow the procedure below to adjust tension of fan belt and V-belt for alternator.

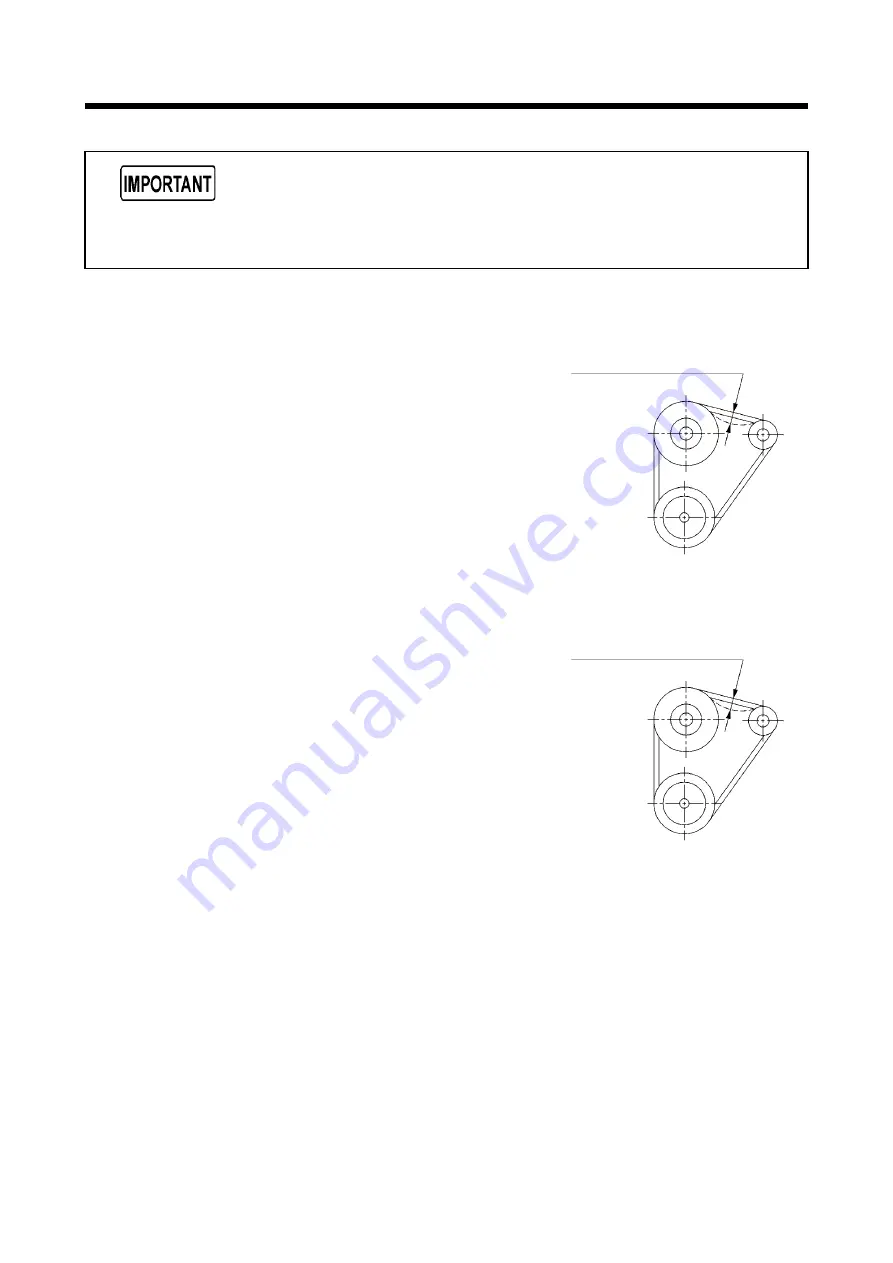

[PDS100S,130S-6B4]

(Procedure)

①

Adjust the tension by gradually loosening the fastening bolt

of the alternator.

②

Visually check if there are any cracks or tears in the belt.

③

Loosen the fastening bolt of the alternator until the play of

the belt reaches 0.2 to 0.3 in. (6.0 to 8.0 mm) when pushed

by fingers, and adjust it.

④

Be careful not to leave any grease or LLC * on a belt while

changing it. If any such material is left, wipe it off

completely.

* Long life coolant

[PDS185S-6B4]

(Procedure)

①

Adjust the tension by gradually loosening the fastening bolt

of the alternator.

②

Visually check if there are any cracks or tears in the belt.

③

Loosen the fastening bolt of the alternator until the play of

the belt reaches 0.32 to 0.45 in. (8.0 to 12.0 mm) when

pushed by fingers, and adjust it.

④

Be careful not to leave any grease or LLC * on a belt while

changing it. If any such material is left, wipe it off

completely.

* Long life coolant

H000041E-2

0.2 to 0.3in.[110bf(49N)]

H000041E-2

0.32 to 0.45in.[22lbf(98.1N)]

Discount-Equipment.com

Summary of Contents for PDS100S-6B4

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m ...

Page 3: ...D i s c o u n t E q u i p m e n t c o m ...

Page 18: ...D i s c o u n t E q u i p m e n t c o m ...

Page 19: ...D i s c o u n t E q u i p m e n t c o m ...

Page 20: ...D i s c o u n t E q u i p m e n t c o m ...

Page 26: ...D i s c o u n t E q u i p m e n t c o m ...

Page 29: ...D i s c o u n t E q u i p m e n t c o m ...

Page 31: ...D i s c o u n t E q u i p m e n t c o m ...

Page 41: ...D i s c o u n t E q u i p m e n t c o m ...

Page 42: ...D i s c o u n t E q u i p m e n t c o m ...

Page 44: ...D i s c o u n t E q u i p m e n t c o m ...

Page 45: ...D i s c o u n t E q u i p m e n t c o m ...

Page 46: ...D i s c o u n t E q u i p m e n t c o m ...

Page 49: ...D i s c o u n t E q u i p m e n t c o m ...

Page 50: ...D i s c o u n t E q u i p m e n t c o m ...

Page 53: ...D i s c o u n t E q u i p m e n t c o m ...

Page 60: ...9 Wiring Diagram 9 1 PDS100S 6B4 PDS130S 6B4 A050044E D i s c o u n t E q u i p m e n t c o m ...

Page 61: ...9 Wiring Diagram 9 2 PDS185S 6B4 A030125 D i s c o u n t E q u i p m e n t c o m ...

Page 62: ...10 Piping Diagram 10 1 PDS100S 6B4 A050211 D i s c o u n t E q u i p m e n t c o m ...

Page 63: ...10 Piping Diagram 10 2 PDS130S 6B4 A050222E 1 D i s c o u n t E q u i p m e n t c o m ...

Page 64: ...10 Piping Diagram 10 3 PDS185S 6B4 A050228 D i s c o u n t E q u i p m e n t c o m ...