2. Maintenance

2-7

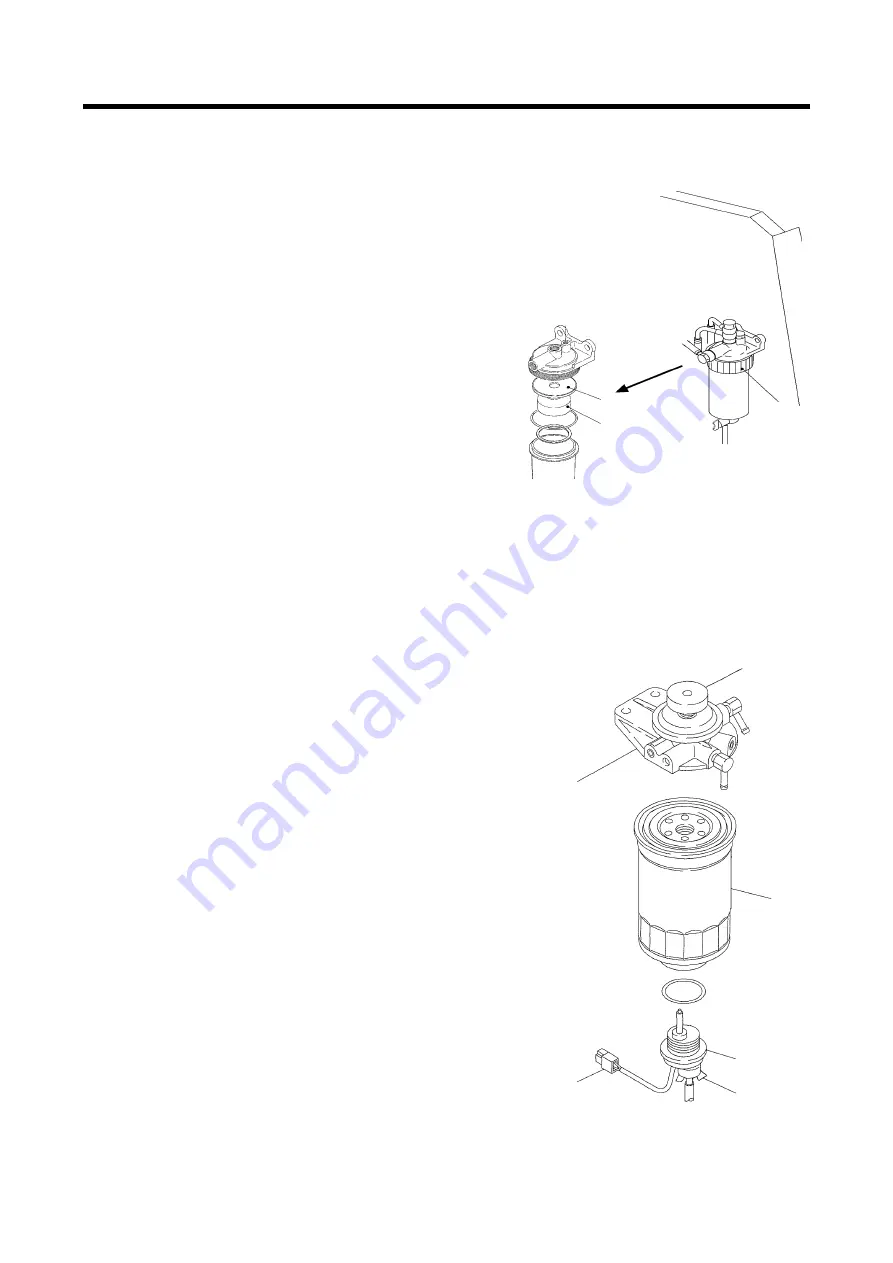

A070305

2.5

Clean the strainer provided inside the sedimenter

(PDS185S-6C1R IN LINE PUMP Type only)

Regularly take off the strainer

“

1

”

in the sedimenter

and wash it.

<

Procedure

>

①

Remove the sedimentor cup

“

2

”

.

②

Turning the bracket

“

3

”

, remove the strainer

“

1

”

.

③

After washing the strainer

“

1

”

with diesel oil, remove

foreign matter by blowing with high pressure air.

④

After finishing cleaning, install all the disassembled

parts in reverse order.

2.6

Change fuel filter (sedimenter built-in type)

(PDS185S-6C1 VE PUMP Type only)

<

Procedure

>

①

Separate the sensor connector

“

1

”

(provided at the lower

part of fuel filter) from the main wiring portion.

②

Loosen the drain valve

“

2

”

and then drain condensate and

residual fuel staying inside the filter into a container etc.

③

Remove the cartridge

“

4

”

from the cover

“

3

”

, using a filter

wrench.

④

Remove the sensor assembly

“

5

”

from the cartridge

“

4

”

.

⑤

Install the sensor assembly

“

5

”

to the new cartridge

“

4

”

.

⑥

New cartridge

“

4

”

please bind tight using a filter wrench.

⑦

After finishing the installation, install the removed

connector

“

1

”

to where it was.

⑧

Finally, press the priming pump

“

6

”

up and down a few

times for air bleeding in fuel line. Continue it till the

pump moves heavily.

6

3

4

5

2

1

2

1

3

Discount-Equipment.com

Summary of Contents for PDS185S-6C1

Page 1: ...D i s c o u n t E q u i p m e n t c o m...

Page 19: ...1 Specification 1 15 1 7 Piping Diagram PC08091E D i s c o u n t E q u i p m e n t c o m...

Page 76: ...5 4 PDS185S 6C1 VE PUMP Type PC08047E D i s c o u n t E q u i p m e n t c o m...

Page 77: ...5 5 PDS185S 6C1R IN LINE PUMP Type PC08048E D i s c o u n t E q u i p m e n t c o m...

Page 78: ...5 6 PDS185S 6C1R IN LINE PUMP Type PC08090E D i s c o u n t E q u i p m e n t c o m...