2. Maintenance

2-9

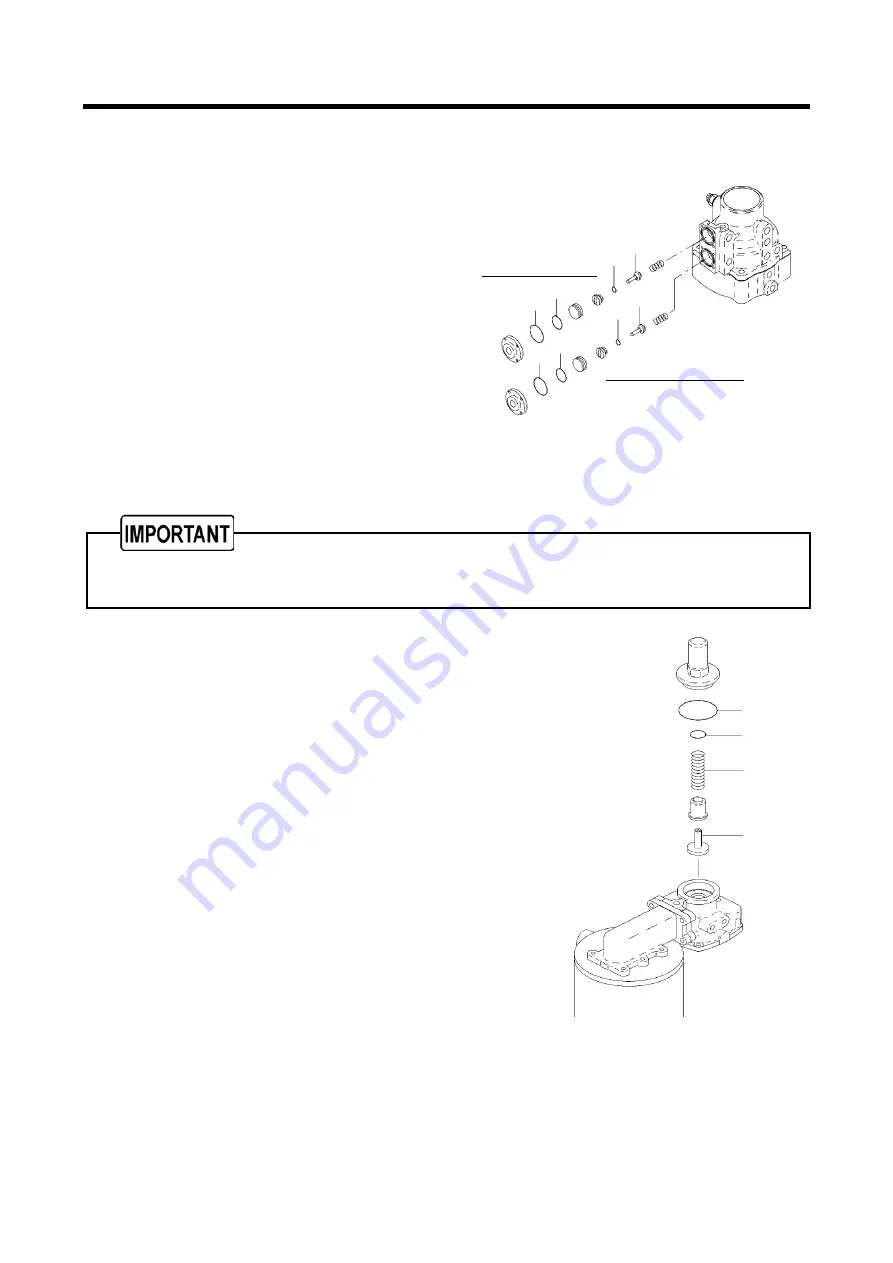

PC08057

Auto-relief valve

2.9

Check O-ring and Needle valve of Auto-relief valve and Vacuum

relief valve

●

Disassemble and clean the component, and check

O-ring

“

1

”

,

“

2

”

,

“

3

”

and needle valve

“

4

”

. Then,

replace O-ring

“

1

”

,

“

2

”

,

“

3

”

and rubber on the

needle valve

“

4

”

, if hardened.

2.10

Performance check of Pressure control valve

When reassembling, apply sufficient grease to O-ring Slot/O-ring and sliding surface.

Use CALTEX MULTIFAK EP1 grease or equivalent. Grease of poor quality will deteriorate the material.

<Procedure>

①

When closing stop valve and fully opening service

valve while the machine is running, make sure that

the discharge pressure gauge shows the figure

between 49-68psi (0.34-0.47MPa).

②

When the pressure is lower than 49psi (0.34MPa),

replace spring

“

3

”

with a new one.

③

When the indicator shows excessively higher

pressure, you will find that the piston does not move

smoothly due to foreign material and rust stuck

inside valve. In such a case, disassemble the

component for checking and cleaning.

2.11

Check Pressure Control Valve O-Ring and Piston

●

Disassemble and clean the component, and check O-ring

“

1

”

,

“

2

”

and the piston

“

4

”

shown in 2.9

then, replace it, if they are hardened.

●

After replacement, run the machine to check its function, air-leak or any disorder.

1

2

3

4

1

2

3

4

Vacuum relief valve

A070338

1

2

3

4

Discount-Equipment.com

Summary of Contents for PDS185S-6C1

Page 1: ...D i s c o u n t E q u i p m e n t c o m...

Page 19: ...1 Specification 1 15 1 7 Piping Diagram PC08091E D i s c o u n t E q u i p m e n t c o m...

Page 76: ...5 4 PDS185S 6C1 VE PUMP Type PC08047E D i s c o u n t E q u i p m e n t c o m...

Page 77: ...5 5 PDS185S 6C1R IN LINE PUMP Type PC08048E D i s c o u n t E q u i p m e n t c o m...

Page 78: ...5 6 PDS185S 6C1R IN LINE PUMP Type PC08090E D i s c o u n t E q u i p m e n t c o m...