3. Electric System

3-9

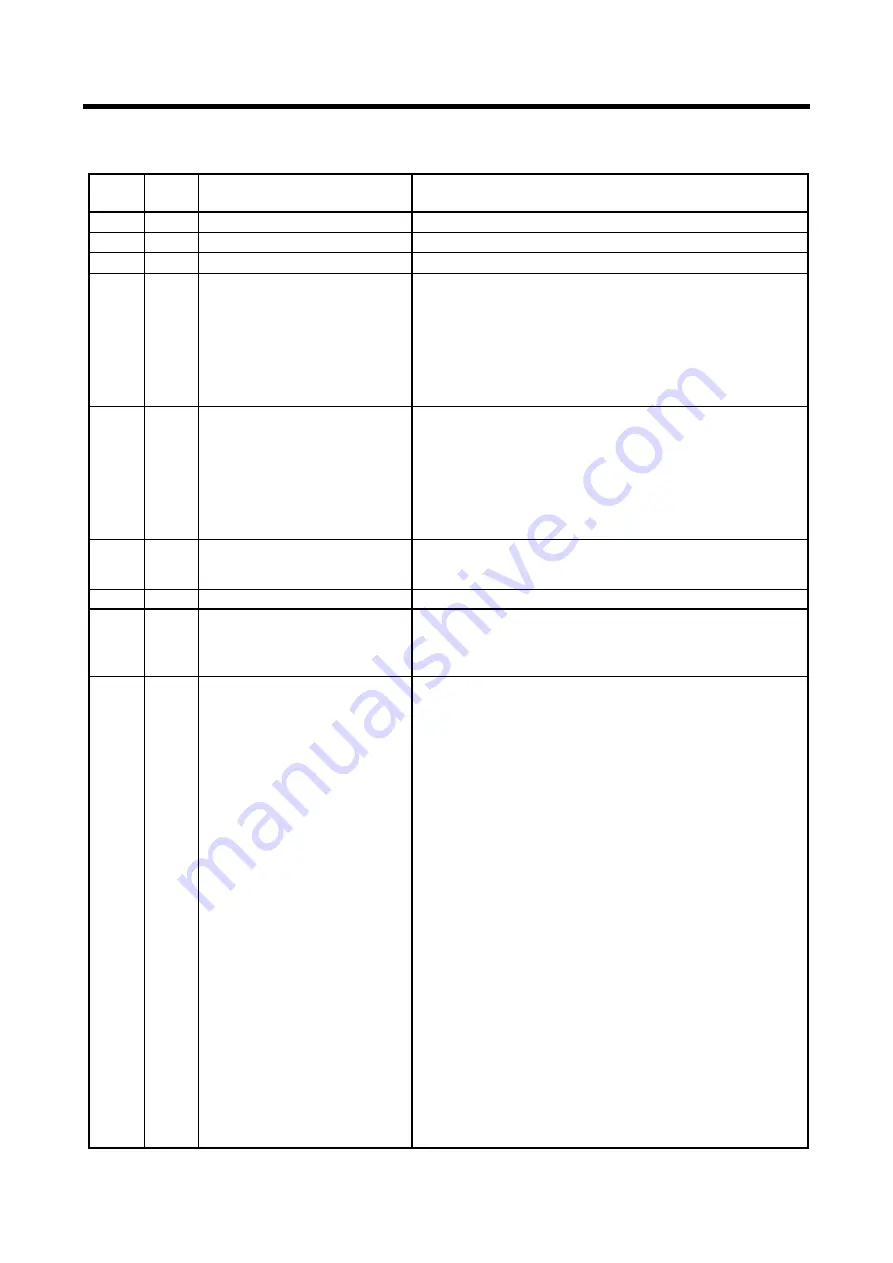

6.List of functions

(1)Connector CN1

Pin No.

Line

color

Connection

Remark

1 B

Earth

2

-

NIL

3 B

Earth

4 W/B

Stop solenoid

[Stop motor relay]

When voltage is applied to CN1-8 terminal by

switching “ON” starter switch, voltage is outputted

from CN1-4 terminal, and it actuates stop solenoid

[stop motor relay].

When starter switch is “OFF” or emergency stop device

functions, interior contact (RY1) between CN1-8 and

CN1-4 terminal gets “OFF” to cut electrical supply and

to cause engine to emergency stop.

5

B/Y Starter relay No.3 terminal

Turn starter switch to “START” and then it gets electrically

connected.

(Starting signal inputted from starter relay No.3 terminal is

sent from CN1-3 terminal to ground connector.)

After starting engine, and when alternator generating signal

is inputted to CN2-17 terminal, interior contact (RY2)

between CN1-5 and CN1-3 terminal gets “OFF” to prevent

overrun of starter motor and plunging of pinion gear.

6

R/Y

[R/W]

10A Fuse

(Through joint connector

No.1 terminal)

Power supply

7

-

NIL

8

R/Y

[R/W]

10A Fuse

(Through joint connector

No.6 terminal)

Power supply for actuation of stop solenoid valve

When starter switch turns “ON”, electricity flows

between CN1-8 and CN1-4 terminal to actuate stop

solenoid valve.

9 L/W

Purge/starting unloader

solenoid valve No.1 terminal

When starter switch is switched “ON” and voltage is

applied to CN1-6 terminal, interior contact (RY3)

between CN1-9 and CN1-3 turns “ON” to get

electrically connected and to open the solenoid valve

when engine starts. Thus it starts starting unloader

operation and makes engine smoothly start at light

load.

When CN2-17 terminal receives alternator generating

signal input after engine starts, controller timer starts

to disengage the contact “OFF” in 10 seconds. Then the

electrical connection is cut to close the valve. This

starting unloader operation of this valve is disengaged

and compressor starts normal operation.

●

When AUTO IDLE (PURGE CONTROL) SWITCH is ON

When pushing AUTO IDLE switch during operation, it

will be switched to purge control operation.

When compressor is transferred to unloaded operation

by reduction of air consumption and intake negative

pressure at secondary aide increases. During operation

of purge control, this sensor detects this negative

pressure and outputs it to controller for operation

control. When the intake valve to controller passes

under the set pressure (standard value: negative

pressure 30%) for a certain time, the interior contact

(RY3) turns “ON”. Thus purge/starting unloader

solenoid valve is electrically connected to open the

valve to reduce the pressure in receiver tank and

switched to purge operation.

The data in [ ] show those of electric apparatus used for PDS185S-6C1R. (IN LINE PUMP type).

Discount-Equipment.com

Summary of Contents for PDS185S-6C1

Page 1: ...D i s c o u n t E q u i p m e n t c o m...

Page 19: ...1 Specification 1 15 1 7 Piping Diagram PC08091E D i s c o u n t E q u i p m e n t c o m...

Page 76: ...5 4 PDS185S 6C1 VE PUMP Type PC08047E D i s c o u n t E q u i p m e n t c o m...

Page 77: ...5 5 PDS185S 6C1R IN LINE PUMP Type PC08048E D i s c o u n t E q u i p m e n t c o m...

Page 78: ...5 6 PDS185S 6C1R IN LINE PUMP Type PC08090E D i s c o u n t E q u i p m e n t c o m...