1. Specification

1-9

1.6

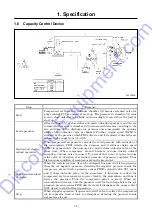

Capacity Control Device

A131023E

Step Response

Start

Compressed air flows into unloader chamber (A) because solenoid valve for

purge control SV1 is opened at start-up. The pressure in chamber (A) rises

soon to close unloader valve fully and accordingly it can reduce the load at

start-up.

Load operation

After starting, SV1 is closed after automatic unloaded operation, and the air

volume which is sent to chamber (A) increases and decreases according to the

rise and drop of the discharge air pressure and consequently the opening

width of the unloader valve is changed. Further, engine speed (RPM) is

changed by the pressure which PRS1

detects, and it steplessly controls the air

volume in the range from 0 to 100%.

Suction port closing

unload operation

When compressed air pressure exceeds the rated pressure with reduction of

air consumption, PRS1 detects the pressure and it reduces engine speed

(RPM) in proportion to the pressure rise, and it closes unloader valve at the

same time. When compressor air-end becomes vacuum during unload

operation, vacuum noise is caused. To prevent this noise, it opens vacuum

relief valve by detection of secondary pressure of pressure regulator. Thus

high vacuum condition of compressor air-end is prevented.

Purge control unload

operation

When the certain set time (it can be changed.) has passed at lower pressure

than the set negative pressure, detecting the negative pressure inside the

compressor air-end with a pressure sensor PRS2, solenoid valve SV1 opens

and it closes unloader valve. At the same time, it functions to relieve the

compressed air from separator receiver tank to the atmosphere and thus it

lowers the pressure. Thus the compressor power is saved. When air

consumption increases, and the pressure used for load drops below the set

pressure, pressure sensor PRS3 detects it and it disengages the purge control

(SV1 closes) to start full load operation.

Stop

When stopping operation, it opens auto-relief valve to relieve the compressed

air in separator receiver tank to atmosphere, detecting the pressure inside

compressor air-end.

Discount-Equipment.com

Summary of Contents for PDS185S-6E1

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m...

Page 10: ...1 Specification 1 4 Unit mm A131025 D i s c o u n t E q u i p m e n t c o m...

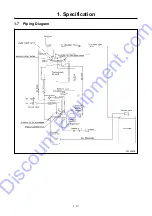

Page 18: ...1 Specification 1 12 1 7 Piping Diagram PC14063E D i s c o u n t E q u i p m e n t c o m...

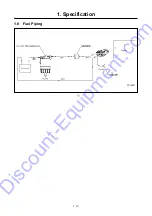

Page 19: ...1 Specification 1 13 1 8 Fuel Piping PC14001 D i s c o u n t E q u i p m e n t c o m...