2. Maintenance

2-10

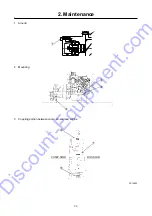

③

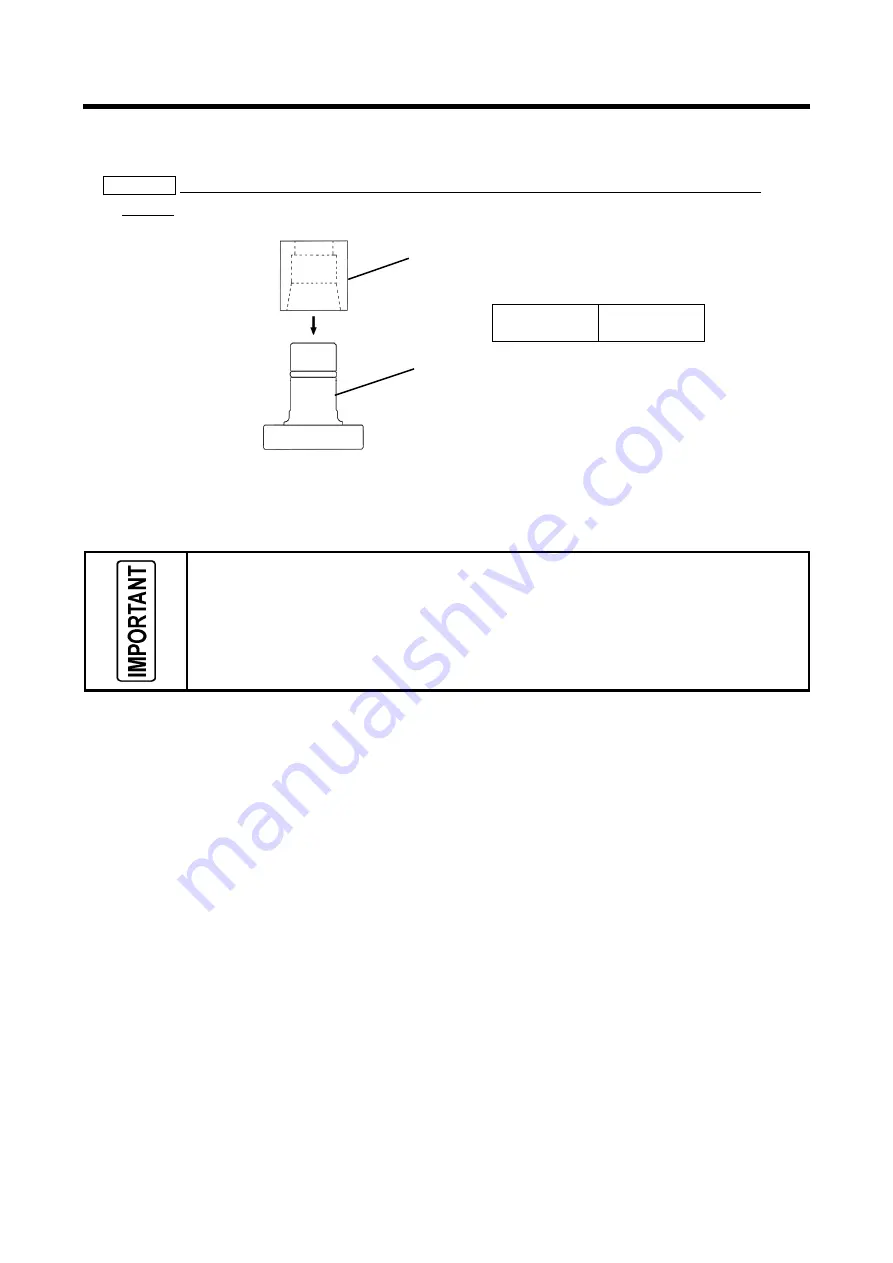

Slightly coat inner circumference portion of the correction tool with grease and insert it into the

piston

“

5

”

and then correct the resin ring.

IMPORTANT

Insert the ring gradually to the piston, correcting it and paying attention not to get

caught.

④

After having inserted it, pull out the correction tool and check and confirm that the resin ring is

properly installed. If deformed, repair it and correct it.

When reinstalling it, check and confirm that there are no foreign matters and dust in

O-ring groove and on the O-ring. Then, coat O-ring with grease slightly.

Use CALTEX MULTIFAK EP1 grease or equivalent. Grease of poor quality will

deteriorate the material.

PC13128

Correction tool

5

Part number

of the tool

00817 00194

Discount-Equipment.com

Summary of Contents for PDS185S-6E1

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m...

Page 10: ...1 Specification 1 4 Unit mm A131025 D i s c o u n t E q u i p m e n t c o m...

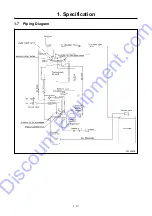

Page 18: ...1 Specification 1 12 1 7 Piping Diagram PC14063E D i s c o u n t E q u i p m e n t c o m...

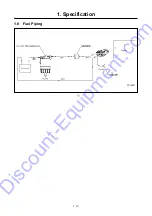

Page 19: ...1 Specification 1 13 1 8 Fuel Piping PC14001 D i s c o u n t E q u i p m e n t c o m...