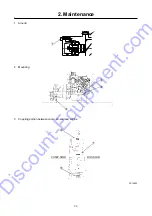

2. Maintenance

2-12

A130986

2.8

Maintenance and Adjustment of Pressure Control Valve

<Procedure>

①

If the discharge pressure drops lower than

51psi(0.35MPa)[3.5bar] during operation, replace

the spring

“

3

”

of pressure control valve. After

confirming that the compressed air in the pipes is

completely relieved, disassemble the valve.

②

When O-ring

“

1

”

and

“

2

”

are found deteriorated

and/or hardened, replace them even before

periodical interval of replacement.

③

When the piston

“

4

”

is found worn or damaged,

replace it.

After replacement, run the machine to check its

function, air-leak or any disorder.

Setting pressure:

58.2 psi(0.4

MPa)[4 bar]

④

When the indicator shows excessively higher

pressure, you will find that the piston does not move

smoothly due to foreign material and rust stuck

inside valve. In such a case, disassemble the

component for checking and cleaning.

When reinstalling it, check and confirm that there are no foreign matters and dust in

O-ring groove and on the O-ring. Then, coat O-ring with grease slightly.

Use CALTEX MULTIFAK EP1 grease or equivalent. Grease of poor quality will

deteriorate the material.

1

2

3

4

+14.6 +0.1

+1

-

1.5

-

0.05

-

0.5

Discount-Equipment.com

Summary of Contents for PDS185S-6E1

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m...

Page 10: ...1 Specification 1 4 Unit mm A131025 D i s c o u n t E q u i p m e n t c o m...

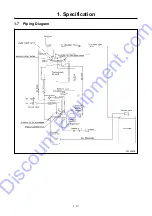

Page 18: ...1 Specification 1 12 1 7 Piping Diagram PC14063E D i s c o u n t E q u i p m e n t c o m...

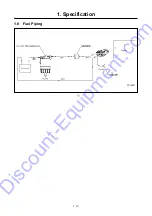

Page 19: ...1 Specification 1 13 1 8 Fuel Piping PC14001 D i s c o u n t E q u i p m e n t c o m...