3. Electric System

3-35

3.16.4

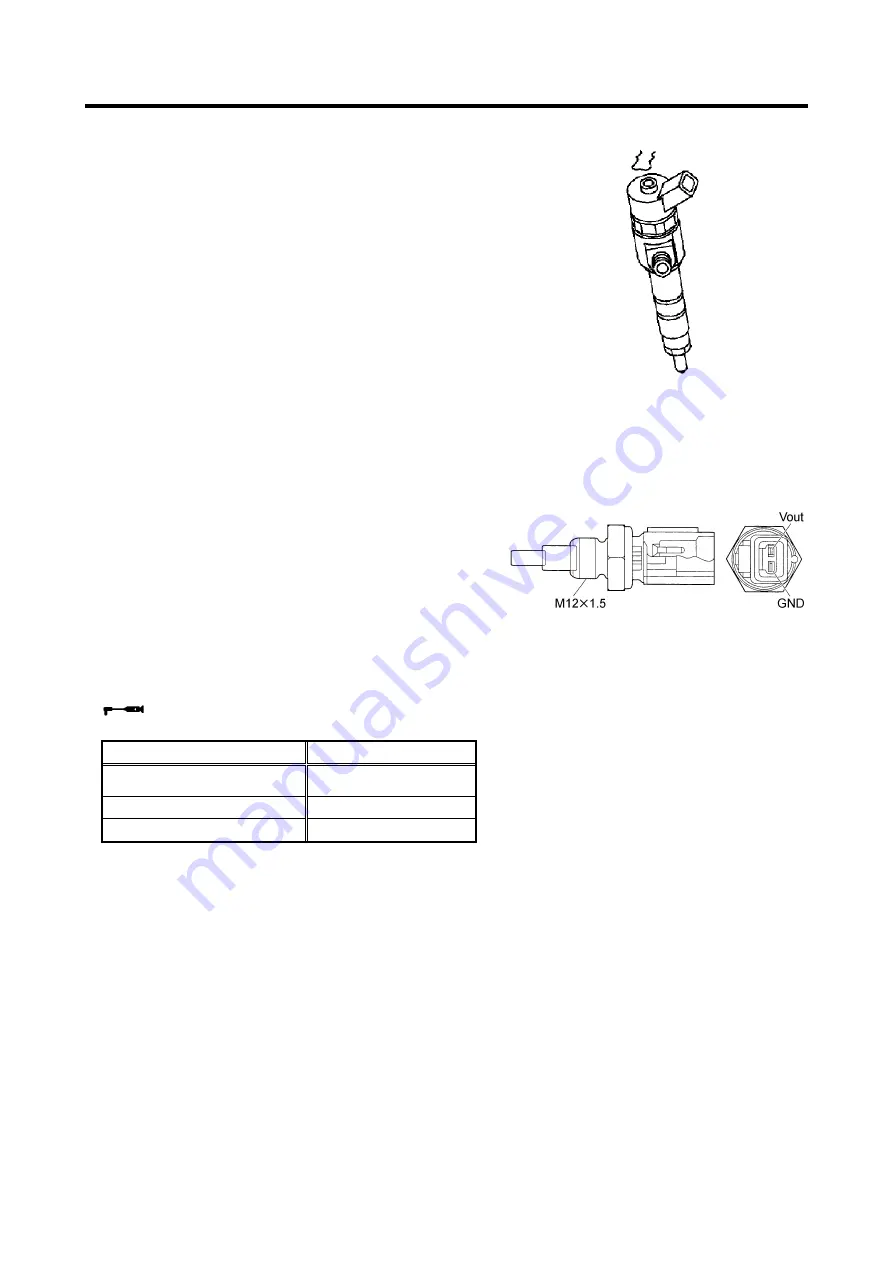

Injector

The ECU controls the injector to maintain optimum

injection volume and injection timing and injects the

high pressure fuel accumulated in the rail into the

cylinder.

Each piece of injector has its correction data for

improvement of injection volume accuracy. The

correction data are printed at the top of each injector,

and are written in ECU. The injection volume is

corrected based on the data. Therefore, it is necessary to

write the data again when injector and ECU are

replaced. Further, take care not to touch any cable at

key on because high volt current flows to injector.

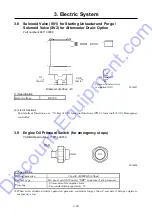

3.16.5

Water temperature sensor (ECU)

Allows the CSD (Cold start device) and EGR (Exhaust

gas recirculation) to be controlled in engine cold-start

conditions. Make sure to use genuine parts and never

use it for other equipment.

YANMAR part number:129927-44900

Installation

:

194.7

±

17.7lbf

・

in. (22

±

2N

・

m) [224

±

20kgf

・

cm]

Coolant temperature °F(

℃

) Resistance value (k

Ω

)

68( 20)

2.45

+

0.14

-

0.13

176( 80)

0.318

±

0.008

212(100) (0.1836)

3.16.6

Water temperature sensor (Gauge)

See 3.11 Discharge Temperature Sensor / Water Temperature Sensor.

3.16.7

Engine oil pressure switch

See 3.9 Engine Oil Pressure Switch.

PC14034

PC14035

Discount-Equipment.com

Summary of Contents for PDS185S-6E1

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m...

Page 10: ...1 Specification 1 4 Unit mm A131025 D i s c o u n t E q u i p m e n t c o m...

Page 18: ...1 Specification 1 12 1 7 Piping Diagram PC14063E D i s c o u n t E q u i p m e n t c o m...

Page 19: ...1 Specification 1 13 1 8 Fuel Piping PC14001 D i s c o u n t E q u i p m e n t c o m...