2. Maintenance

2-17

④

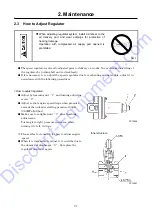

Pull out the suction control valve (SCV).

Note:

・

If it is hard to pull it out due to the resistance on the

O-ring, pull it out while rotating it from side to side.

・

To prevent foreign matter from entering, do not put

gloves on from the next work.

⑤

Remove the O-ring of the suction control valve

(SCV).

Note:

Be careful not to let foreign matter enter the pump

housing at removal.

⑥

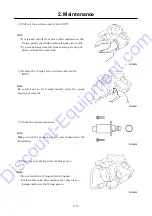

Check the replacement part.

Note:

Make sure that you have got all parts indicated in the

illustration.

⑦

Place the new O-ring in the O-ring groove.

Note:

・

Do not touch the O-ring with dirty hands.

・

Perform this work after making sure there is no

foreign matter in the O-ring groove.

SG09046

SG09047

SG09048

SG09049

Discount-Equipment.com

Summary of Contents for PDS400S-6C3

Page 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m ...

Page 10: ...1 Specification 1 4 PC14064E Unit mm D i s c o u n t E q u i p m e n t c o m ...

Page 19: ...1 Specification 1 13 Aftercooler type A120195E D i s c o u n t E q u i p m e n t c o m ...

Page 20: ...1 Specification 1 14 1 8 Fuel Piping PC13053E D i s c o u n t E q u i p m e n t c o m ...

Page 101: ...5 3 5 2 Engine Wiring Diagram PC13087E PC13088 D i s c o u n t E q u i p m e n t c o m ...