3.Operation

3-10

3.3.8

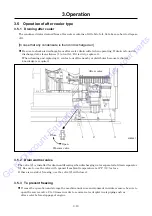

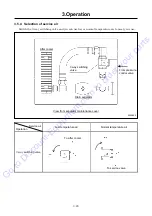

Check sedimenter for condensate

When red float [B] under element [A] in fuel filter is raised up to upper level, drain water.

<Procedure>

1.

Turn fuel selector valve [C] to “OFF”position.

2.

Loosen the drain valve [D] and drain out condensed

water inside.

3.

Make sure to tighten the drain valve [D] securely,

after draining the condensate.

Drain the condensate in container [E] and then

dispose of condensate according to the designated

regulations.

When checking, do not use alcoholic parts cleaner for cleaning. If it sticks to plastic

parts, which might causes cracks and less visual recognition for fuel level. In worst

case, which might causes cracks and fuel leaks.

3.3.9

Check wiring of each part

Check each wiring for any loose connection, damage to insulating sheathed portion, disconnection,

and short-circuit.

3.3.10

Check piping of each part

Check each piping for any loose connection and also check each hose and pipe for any tear and

leaks.

3.3.11

Check in the machine

Periodically check the inside of the machine for dust and flammables.

Be sure to wear protector such as helmet, protective glasses, earplug, safety shoes,

gloves and dust protective mask for safety operation conforming with details of work.

Temperature of muffler and exhaust valve will become high. Be sure to remove

combustibles such woodchip, dead leaf,

waste paper nearby it.

Just in case for fire, be sure to set fire extinguisher nearby machine.

It is helpful to keep emergency contact numbers for urgent visit clinic, ambulance and

firehouse.

A130567-2

E

A

B

D

OFF

ON

C

Loosen

Go

to

Discount-Equipment.com

to

order

your

parts