3.Operation

3-12

3.4

Operating Procedure

For proper cooling and airflow, make sure that all enclosure doors are closed before starting.

3.4.1

Procedure to start the unit

Start-up procedure.

During the warm-up operation, examine the different parts of the equipment for any looseness,

leakage of water, oil, fuel, and other irregularities.

Also, make sure that diagnosis lamp is off.

<Procedure>

1.

Close fully service valve.

2.

Set the “CONTROL POWER” switch to

from

.

3.

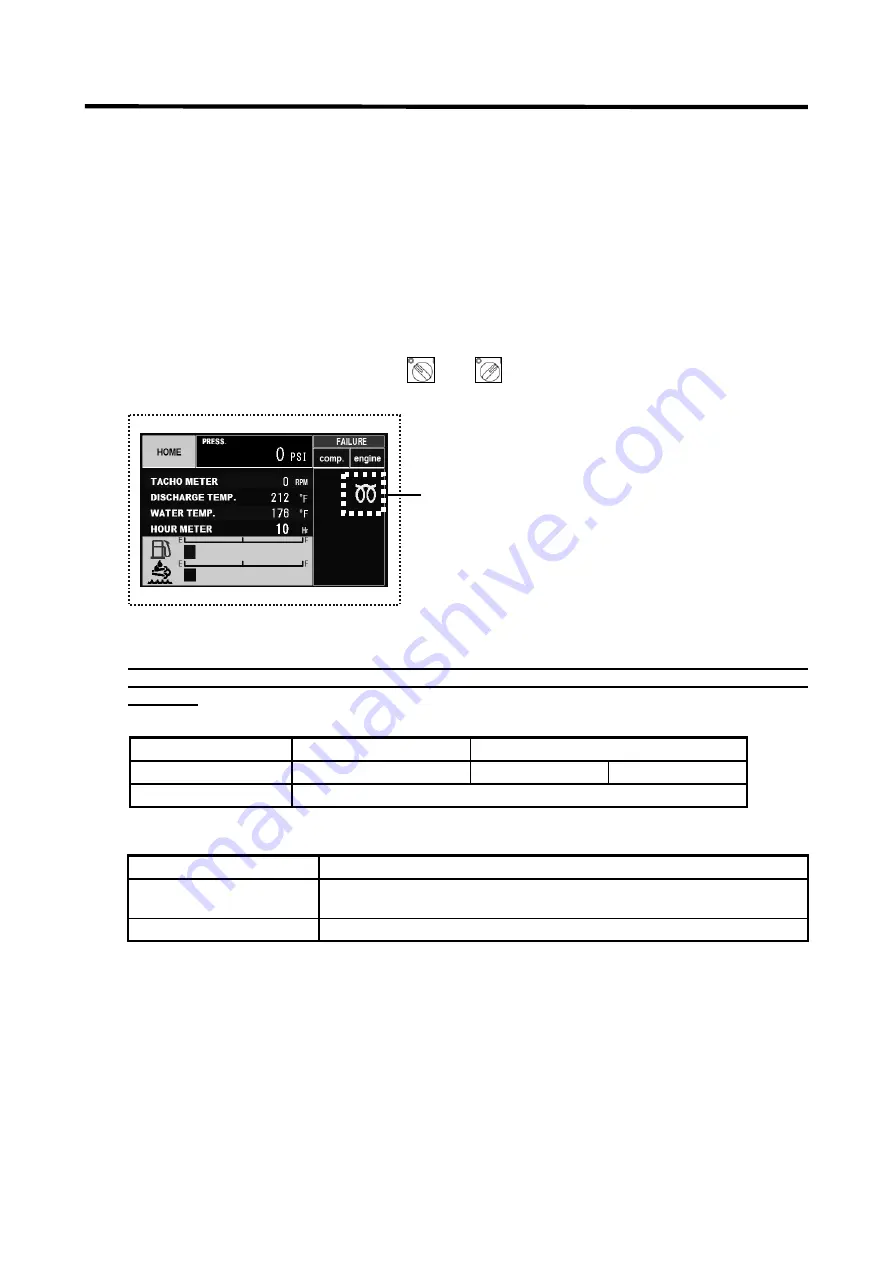

Make sure that the pressure reading [PRESS.] on the home screen indicates [0] PSI.

4.

Once the glow lamp [A] is extinguished, press the [START] button for 1 second or longer to start

the engine.

The starter switch will stop itself automatically after 15 seconds. Wait at least one minute for

any subsequent starting operation; otherwise, the starter motor may overheat and become

damaged.

(See 3.4.8)

See the table below for starting unloader operation. It varies according engine speed.

The time of starting unloader operation changes according to the discharge air temperature as

mentioned in the following table.

Discharge air temperature

Required time for starting unloader operation

Lower than

140°F(60

℃

)

It exceeds 120 seconds or 30 seconds or certain seconds until discharge air

temperature becomes

140°F(60

℃

)

or more degrees which comes first.

Higher than

140°F(60

℃

)

30 seconds

PDS400S,SC-6E1

PDSF330DP,DPC-6E1

Usage pressure

100PSI

150PSI

100PSI

Engine speed

About 1,450rpm

A

Go

to

Discount-Equipment.com

to

order

your

parts