3.Operation

3-17

3.4.6

Displays during operation

Be sure to check at times to see if screen indicates or each component of the unit are properly

working, or if there is any air-leak, oil-leak, water-leak or fuel-leak etc.

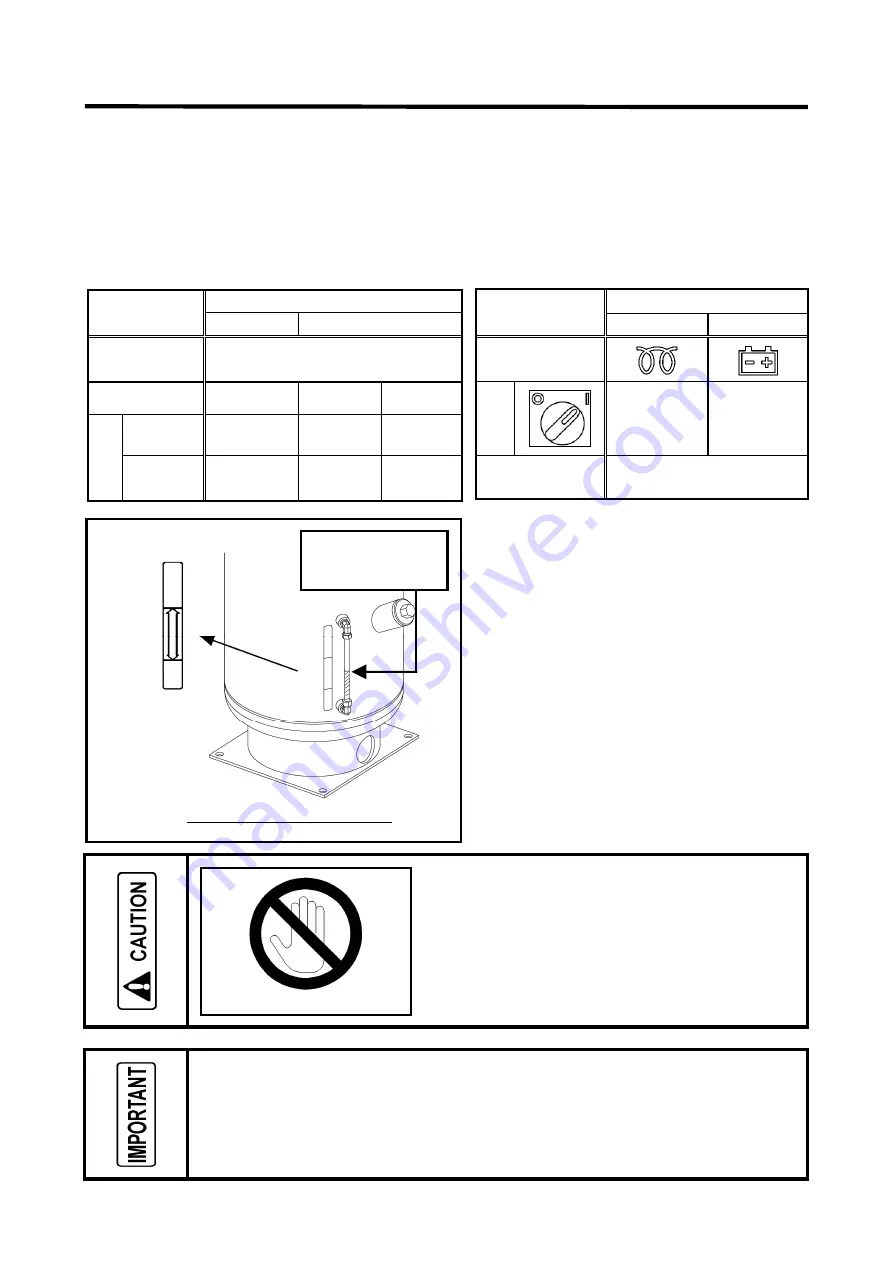

During normal operation, each indication of instruments is shown in the table below. Refer to the

table for daily checks.

The above table gives standard values. They may vary slightly depending on the operating

conditions and other factors.

When the machine is in operation under load,

check to see that the compressor's oil level

falls within the range between the lower limit

and upper limit of the level gauge if the level

is found to be insufficient, replenish the oil.

※

Keep the operation log to record constant

inspection of each component, so that trouble of

the machine can be easily discovered and

preventive measures can be taken.

Do not open the valves below listed when operating.

Separator receiver tank drain valve

Coolant drain valve

Engine oil drain valve

Oil cooler drain valve

Fuel tank drain valve

Make sure that discharge pressure always reads at least

58PSI

during operation.

If you keep operating with less than

58PSI

, it will causes less separation of lubricating

oil at oil separator, or baking caused by overheat of compressor body.

Discharge pressure

PDS400S,SC-6E1

PDSF330DP,DPC-6E1

Starting unloaded

operation

About 15 to 29PSI

Usage pressure

100PSI 150PSI 100PSI

In op

eratio

n

No load

(Unload)

100 to 131PSI 150 to 174PSI 100 to 131PSI

Full load

58 to 100PSI 58 to 150PSI 58 to 100PSI

Oil quantity during operation

A160698

Upper limit

Lower limit

Protection device

Indicator

GLOW CHARGE

Monitor

Befo

re

st

ar

tu

p

-

ON

In operation

OFF

PK0028

Proper oil level

when the machine

is in operation.

Go

to

Discount-Equipment.com

to

order

your

parts