5.Periodic inspection/Maintenance

5-11

5.5.7

Change compressor oil filter element

At 300 hours for the first change and every 500 hours thereafter

Be sure to use genuine filter element.

<

Procedure

>

1.

Remove the oil filter element [A], using a filter wrench.

2.

Screw in the new oil filter element [A] with the packing

[B] coated slightly with oil.

(For part number, See 5.4)

3.

After the packing touches the sealing face, tighten

another

1/2 to 3/4

turn with a filter wrench.

4.

After installing the oil filter element, check it for any

leak during operation.

Poor quality oil filter elements do not trap dust sufficiently and will cause damage to

the bearings in a short period. Be sure to use genuine parts.

5.5.8

Change air filter element

Every 500 hours

Be sure to use genuine air filter element.

<Procedure>

1.

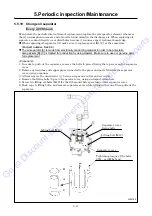

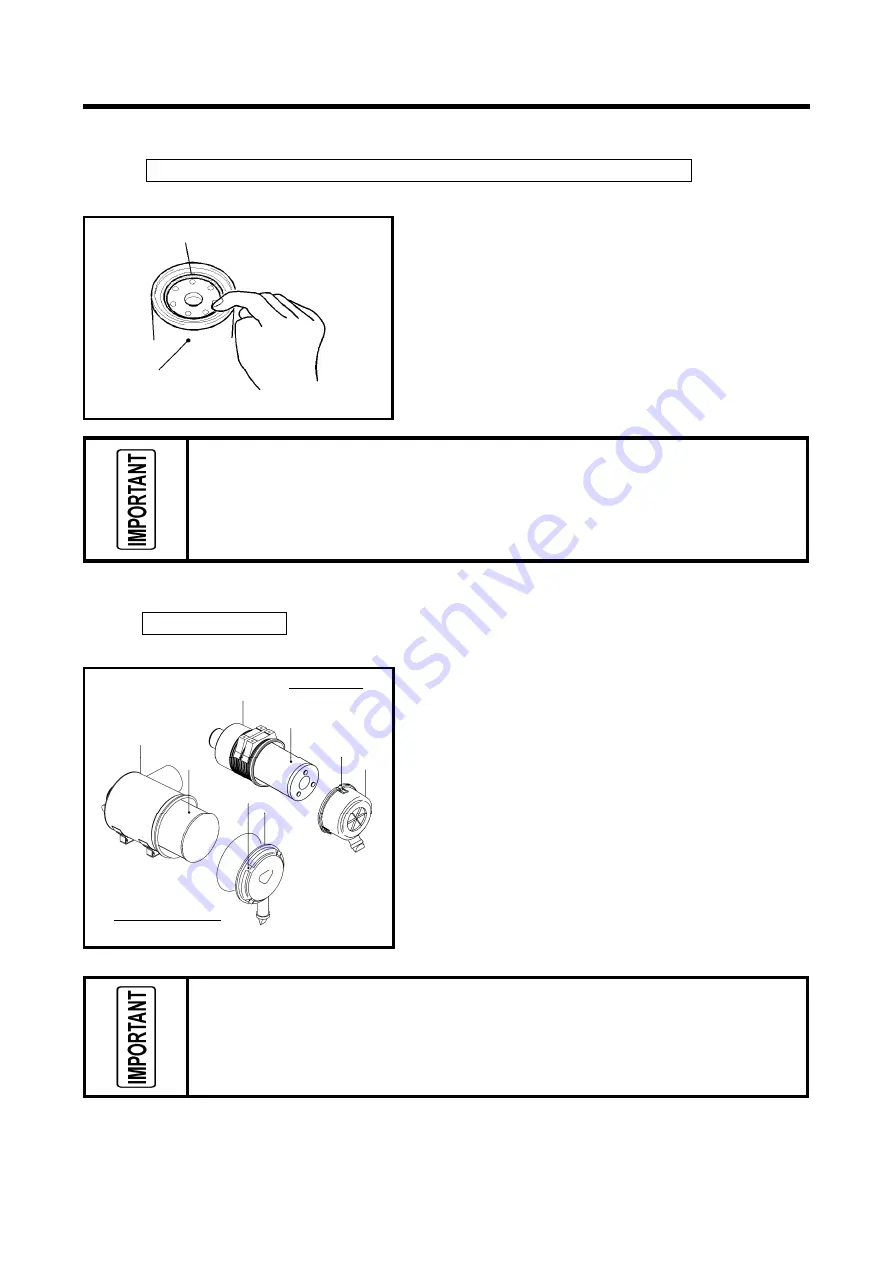

Loosen the cap fix latch [B] at cap [A], then remove cap

and clean inside.

2.

Remove element [C] & [D] and replace it with new one.

(For part number, See 5.4)

3.

When putting cap after replacing, push it into case [E]

with your hand and fasten it after checking the hook of

cap fix latch is set to case.

When used or operated under bad conditions, it is

better to remove all the elements, check them, clean

them and replace them earlier before the intervals

listed in maintenance table, if they are found difficult

to be repaired.

Air filter is an important part which is crucial to machine's performance and life.

Be sure to use genuine parts.

H000049

B

A

A150824

E

For engine

For compressor

D

B

A

E

C

B A

Go

to

Discount-Equipment.com

to

order

your

parts