3. Installation

3

-

1

3.1 Transportation

When loading and unloading unit, be sure to use the lifting bail provided on the center of the unit top.

Never get under the unit which is suspended, because it is very dangerous.

When unit is transferred or moved from working site, be sure to place it on truck bed, and fasten it by

ropes at the front and rear hooks.

Be sure to put one set of chocks to fix its wheels firmly on the truck bed.Never lift unit which is still in

operation, or it could cause critical damage to each component or lead to serious accident.

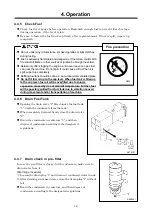

3.1.1

Lifting up

①

Before lifting the unit up, make sure to check the lifting

bail

2 for any crack and loosened bolts.

②

Connect the hook 1 of the crane or shackle with lifting bail

2 eye fitted at the top center of the unit, and make sure

that there is no person standing around the unit. Then

perform hoisting operation.

③

Use auxiliary ropes 3 to prevent the unit from swinging

and/or twisting, giving signs and signals each other.

④

Select a truck or a crane with capacity sufficient for weight

and size of the unit by referring to the values shown in

Chapter 8 “Specifications“ of the manual.

⑤

Never lift the unit while it is running, or this could cause

a serious accident.

3.1.2

Mounting the unit on the truck bed

Be sure to fasten the unit with ropes 1 as shown in the

figure right, and securely fix it on the truck bed.

Be sure to put one set of chocks 2 to the wheels.pull the

parking brake lever it firmly after the unit is loaded on the

truck bed.

A030117

A010190

3

1

3

2

1 2 2 1

Transportation

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......