4.Operation

4

-

9

A070127

4.4.5 Check Fuel

Check fuel level gauge before operation. Replenish enough fuel to prevent fuel shortage

during operation, if the level is low.

Be sure to fasten the fuel tank cap firmly after replenishment. If fuel is spilt, wipe it up

completely.

Do not, under any circumstance, smoke cigarettes or light matches

during fueling.

Fuel is extremely flammable and dangerous. It therefore, could catch

fire should it flame or other sources of ignition be brought near fuel.

Refuel only after stopping the engine, and never leave an open fuel

can near the machine. Do not spill. It could cause a fire. When it is

spilt, wipe it up completely.

Refilling fuel tank should be done in an outdoor well-ventilated place.

Do not fill fuel oil up to the cap level. When fuel tank is filled up

to the cap level, fuel oil will be overfilled due to volume

expansion caused by rise of ambient temperature. Further, fuel

will be possibly spilled from fuel tank due to vibration caused

during movement and/or transportation of machine.

D004

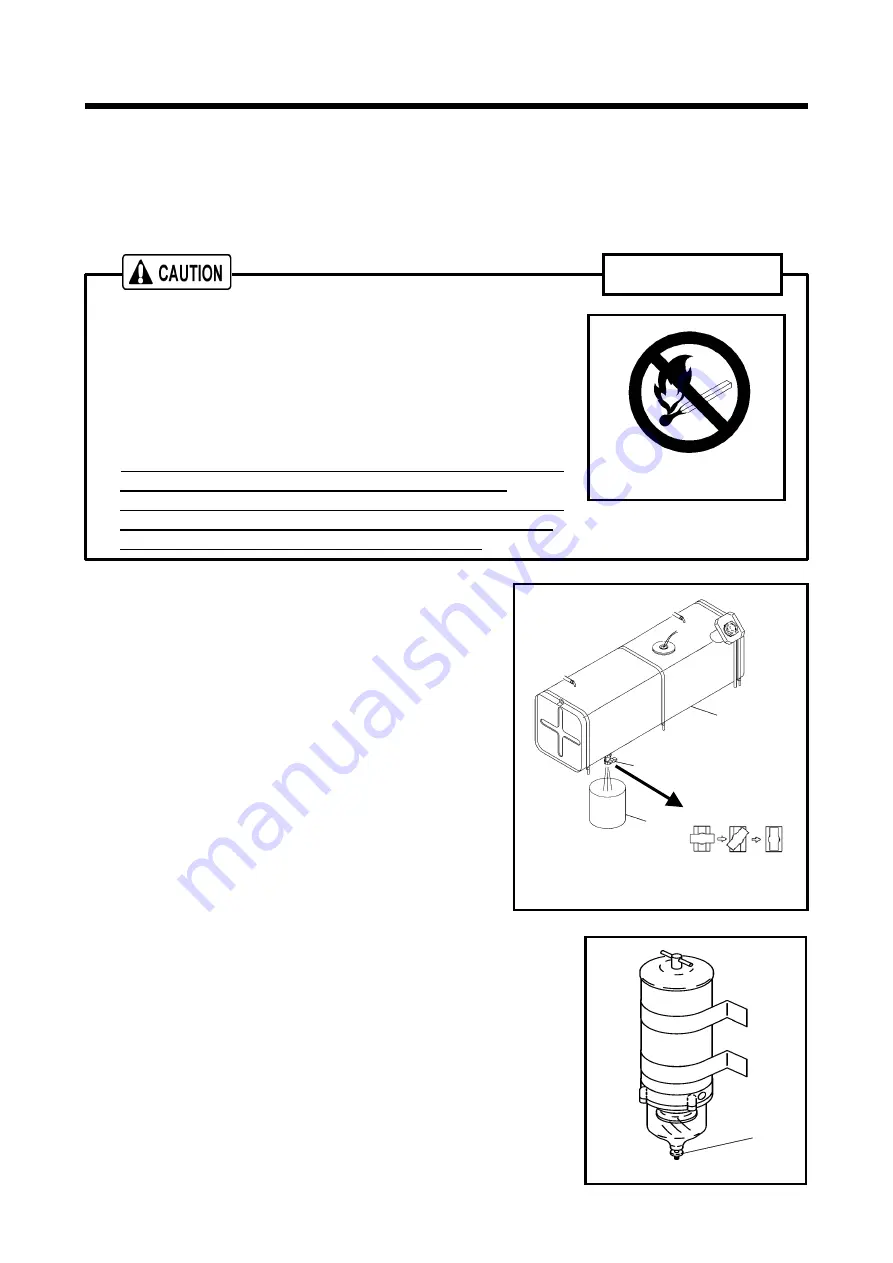

4.4.6 Drain Fuel Tank

Opening the drain valve “2” fitted under the fuel tank

“1”, drain the condensate from the tank.

When completely drained, firmly close the drain valve

“2”.

Drain the condensate in container “3”, and then

dispose of condensate according to the designated

regulations.

4.4.7 Drain check in pre- filter

In case the pre-filter is clogged with condensate, make sure to

drain water from it.

(Draining procedure)

①

Loosen the drain plug “1” and drain out condensed water inside.

②

After draining condensed water, close the drain plug “1” without

fail.

Drain the condensate in container, and then dispose of

condensate according to the designated regulations.

FULLY

OPEN

Fire prevention

CLOSE OPEN

1

2

3

A050441

1

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......