4.Operation

4

-

10

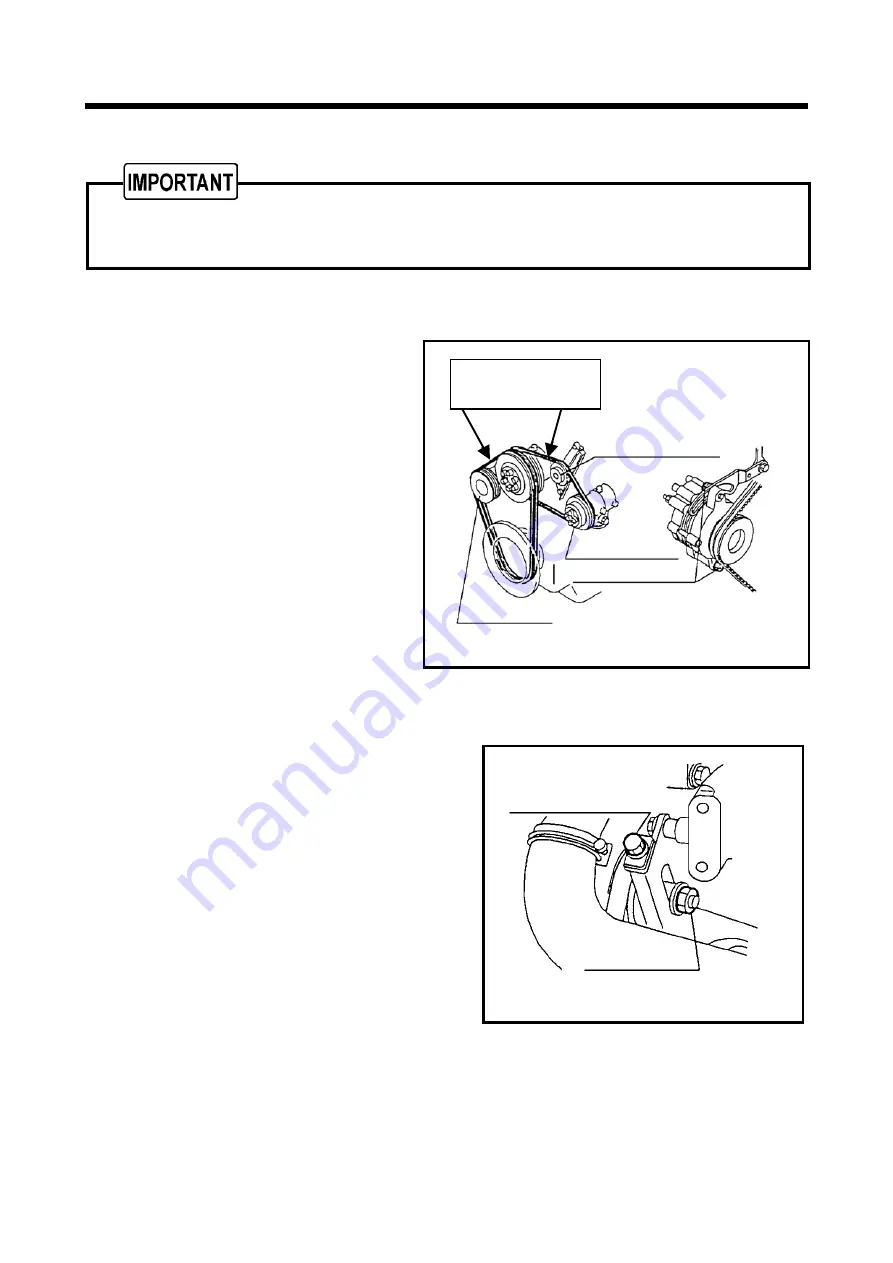

4.4.8 Check Belt Tension

Too tight belt tension could damage shaft and shorten bearing life. Too loose belt tension may result in

damaging belt earlier and machine components due to overheat.

1.

Check the alternator belt of cooling fan

(Procedure)

①

Adjust the tension by gradually

loosening the fastening bolt of the

alternator.

②

Visually check if there are any cracks or

tears in the belt.

③

Loosen the fastening bolt of the

alternator until the play of the belt

reaches 10 to 15mm[98N(10kgf)] when

pushed by fingers, and adjust it.

④

Be careful not to leave any grease or

LLC on a belt while changing it. If any

such material is left, wipe it off

completely.

2.

Check the water pump belt

(Procedure)

①

After loosening the nut fixing the tension pulley,

adjust the belt by moving the pulley with the

adjusting bolt.

②

While adjusting the belt tension, check it for

any crack or wear, and if any fault is found,

replace it.

③

Be careful not to leave any grease or LLC on a

belt while changing it. If any such material is

left, wipe it off completely.

Then check the deflection of

the belt and make sure that

it shall be 10 to 15mm.

Depress the middle of

The belt with a finger

Tension pulley

Alternator

Water pump

Adjusting bolt

TR0426

TR0427

Adjust the belts

Attachment nut

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......