4.Operation

4

-

13

4.5.2 Operating Procedures when Engine Fails to Start up on First Attempt

When the engine fails to start up even after performing the startup procedures

①

to

⑤

,

do not

keep the starter running, but set the starter switch back to

“

STOP

”

and wait about 30 seconds.

Then, repeat the startup procedure once again.

If the repeated procedure does not allow the engine to run, the following causes are suspected.

Therefore, check the following:

No fuel

Clogging of fuel filter

Clogging of gauze filter at the inlet of fuel feed pump.

Clogging of fuel pre-filter

Discharge of battery (Low cranking speed)

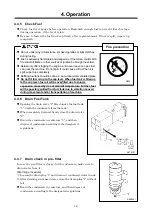

4.5.3 How to Start the Unit at Low Temperature

Use SAE10W-30 (CD class) for the engine oil.

Use LLC (antifreeze). Use correct amount to provide freeze protection, according to the ambient tem-

perature.

Battery should always be kept fully charged.

When temperature is very low and it is difficult to start engine, follow the procedure shown below

to start the unit.

(Procedure)

①

Full open the service valve, and also fully open only

relief valve

“

2

”

on the separator receiver tank

“

1

”

.

②

Follow the regular starting procedure to start the engine.

By watching how the engine rotates, gradually close the

relief valve

“

2

”

as the engine speeds up. When the valve

is completely closed, keep the unit running in this way

for a while for warming-up.

FULLY

OPEN

CLOSE

Operation under Cold Weather Conditions below -5°C

A070198

1

2

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......