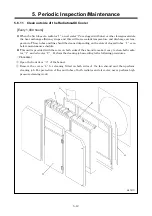

5. Periodic Inspection/Maintenance

5

-

1

5.1 Important Items at Periodic Inspection and Maintenance or after

Maintenance

The manual shows proper interval for periodic inspection and maintenance under normally op-

erating conditions. Inspection and maintenance should be performed more often under ex-

tremely harsh conditions.

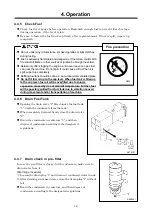

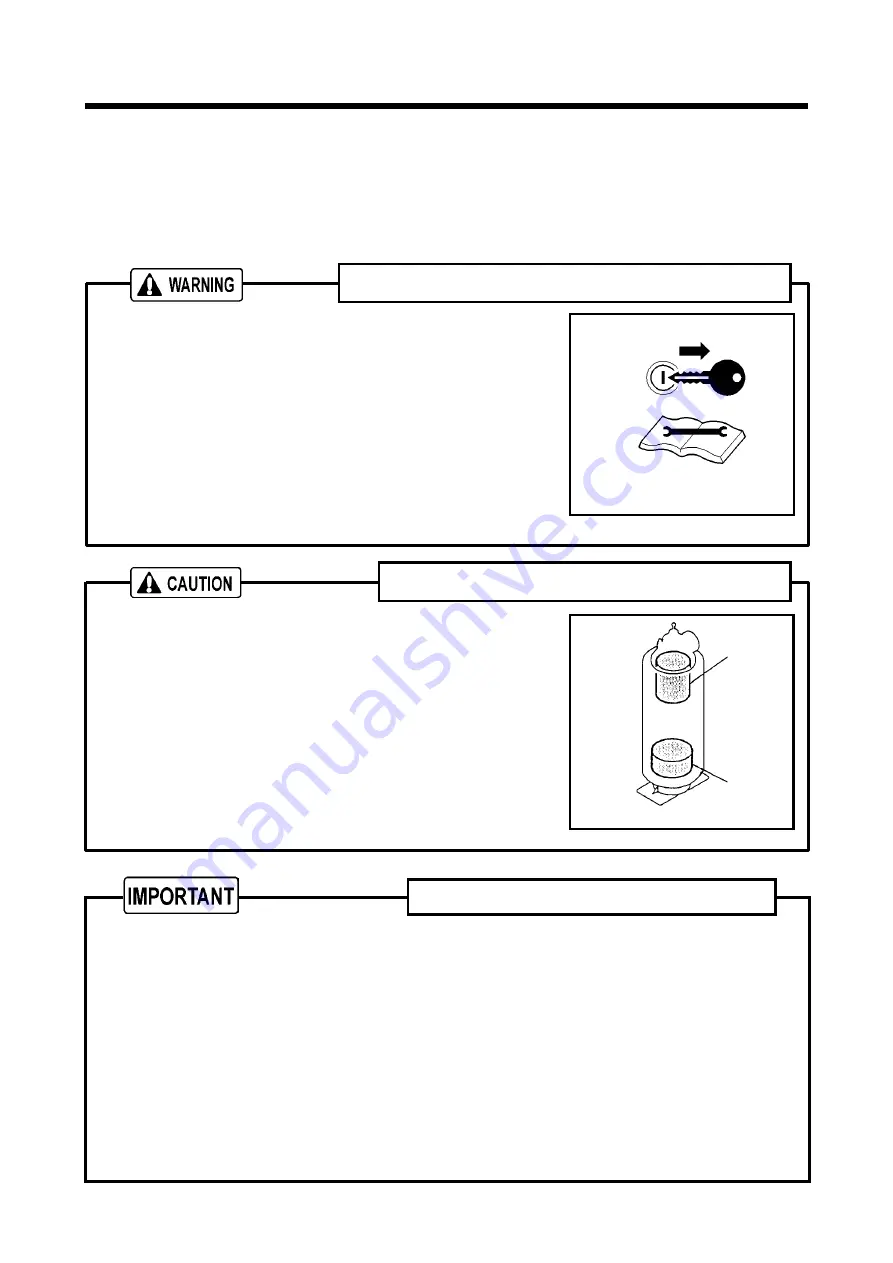

Hang a “Now Checking and under Maintenance” tag

Remove the starter key from the starter switch before starting

inspection, and hang up a “Now Checking and under Mainte-

nance” tag where it can be easily seen. The checker must keep

the key during checking and maintenance.

Remove the negative (–) side cable from the battery.

If the above procedure is neglected, and another person starts

operating the machine during check or maintenance, it could

cause serious injury.

Use tools appropriate for the inspection and maintenance. Any

makeshift or improper tools could cause unexpectedly injury by

their slippage.

SY001

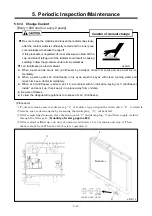

Prevention of oil separator from catching fire

Be sure to perform oil change basically according to the speci-

fied interval. But if such oil is found much more contaminated

before the interval, change the oil even before the specified pe-

riod comes. In doing so, replace the oil completely and use our

recommended oil.

Be sure to perform following periodic inspection and mainte-

nance:

1. Check and change compressor oil

2. Change oil separator

Never mix the oil of different brands, or the mixed oil may dete-

riorate the oil quality.

Be sure to use recommended fuel, oil, grease, and antifreeze.

Do not disassemble or adjust engine, compressor or part(s) for which inspection or maintenance is not

referred to in this manual.

Use genuine parts for replacement.

Any breakdown, caused by using unapproved parts or by wrong handling, will be out of the scope of

“WARRANTY”.

Keep the electrical components away from water or steam.

Waste from machines contains harmful material. Do not dispose of such harmful fluids to the ground,

rivers, lakes or ponds, and sea. It contaminates the environment.

When draining waste fluid from machines, use leakproof containers to hold such fluids from machine.

Be sure to follow the designated regulations when disposing of oil, fuel, coolant, filters, battery and other

harmful things.

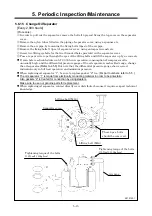

2

1

TR0423

Precautions for check and maintenance

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......