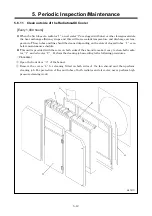

5. Periodic Inspection/Maintenance

5

-

3

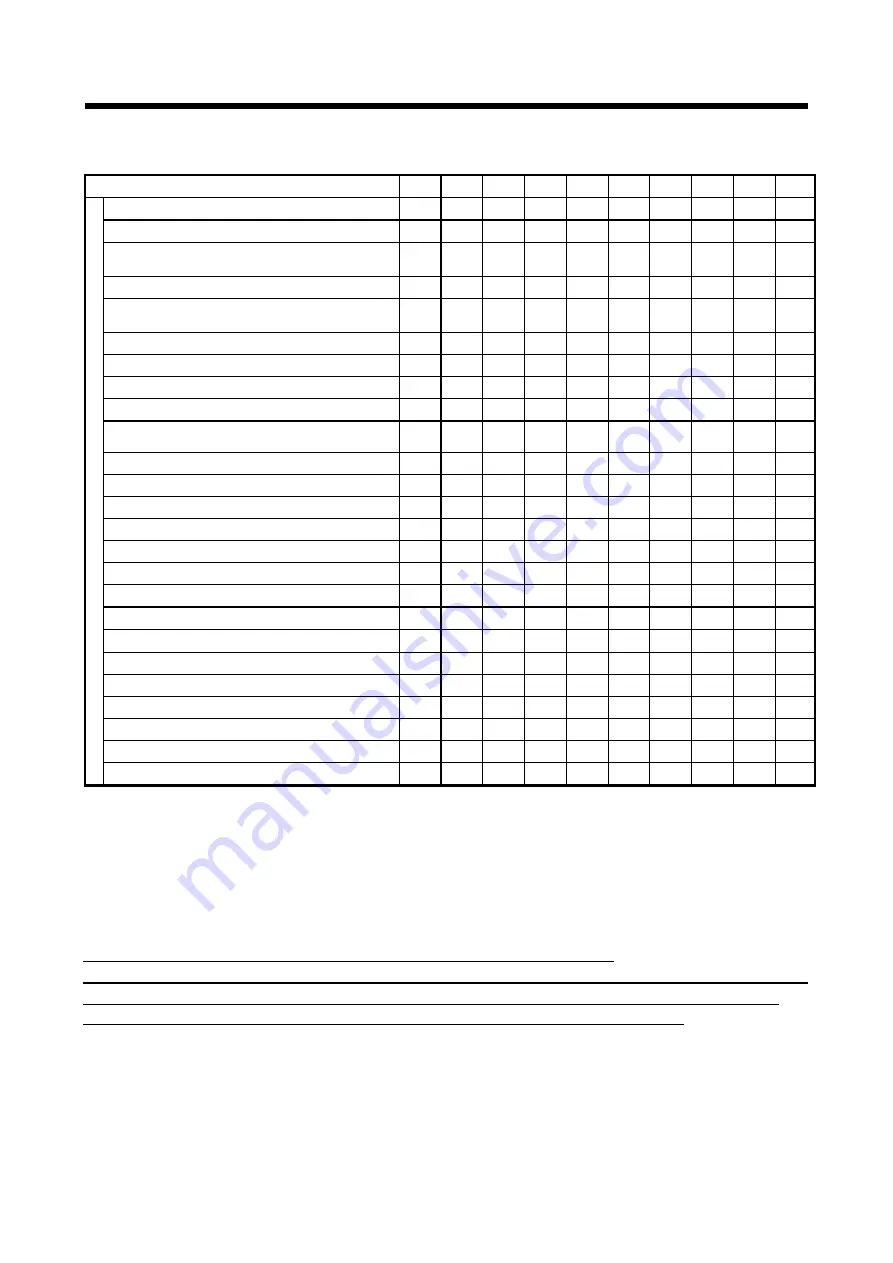

5.4 Periodic Inspection List

(Unit:Hour)

Maintenance

Daily

250

300

500

1,000 2,000 3,000 6,000 12,000 Page

Check compressor oil level.

○

4-8

Drain separator receiver tank.

○

4-8

Check looseness in pipe connecting part, and

wear and tear of pipe.

○

4-11

Check oil, water, fuel and air leak.

○

4-14

Check performance of gauge and indication

lamps.

○

4-14

Performance Check of Safety Valve.

○

4-15

Change compressor oil.

※○

○

5-8

Change compressor oil filter.

※○

○

5-9

Clean strainer in the scavenging orifice.

○

5-10

Clean and change air filter element.

○

○

5-7

Clean outside of the oil cooler.

○

5-12

Supply grease to trailer spring pin

○

5-13

Change pressure regulator diaphragm.

☆●

Change oil separator.

●

5-15

Change nylon tubes.

☆●

Change rubber hoses.

★●

O-ring change of a piping terminal area

★●

Check diaphragm of auto-relief valve.

★●

Check o-ring of auto-relief valve.

★●

Clean butterfly valve (unloader)

●

Change diaphragm of vacuum-relief valve

★●

Change o-ring of vacuum-relief valve

●

Change o-ring of pressure control valve

●

Change rubber coupling.

●

Com

pres

so

r

Change oil seal/bearing

●

Such items marked

○

shall be carried out by customers.

For the following items or clauses marked

●

, contact us directly or our distributors because they require

expert technical knowledge on them.

The following table shows the inspection and maintenance intervals under normal operation

conditions. In case the unit is operated under harsh environmental conditions and operation

conditions, the intervals should be shortened.

The items or parts marked

※

1 show that they should be replaced primarily.

The items or parts marked

☆

should be replaced every two years even if they are not in disorder within their

periodical maintenance interval because their materials will change or become degraded as time passes.

Also for the same reason, the parts marked

★

should be replaced every three years.

Clean

Change

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......