5. Periodic Inspection/Maintenance

5

-

4

◎

Refer to engine operation manual for inspection and maintenance of an engine.

(Unit:Hour)

Maintenance

Daily

50 250

500

1,000 2,000 3,000 6,000 Page

Check fuel

○

4-9

Drain fuel tank

○

4-9

Drain check in pre- filter

○

4-9

Check engine oil level.

○

4-6

Check coolant level.

○

4-7

Check looseness in pipe connectors, terminals

and tear in wiring.

○

4-11

Check belt tension.

○

4-10

Change engine oil.

※○

○

5-5

Change engine oil filter.

※○

○

5-6

Check battery

electrolyte.

○

5-6

Clean and change air filter element.

○

○

5-7

Change fuel filter.

○

5-11

Change filter of Pre-filter

○

5-11

Clean outside of radiator.

○

5-12

Change coolant.

☆○

5-14

Clean the strainer provided inside the engine

feed pump.

○

5-13

Check fuel hose.

☆●

5-16

Clean inside of radiator.

●

Clean inside of fuel tank.

●

Change radiator hoses.

☆●

Eng

ine

Change wiring harness.

●

The items or parts marked

※

show that they should be replaced primarily.

The items or parts marked

☆

should be replaced every two years even if they are not in disorder within their

periodical maintenance interval because their materials will change or become degraded as time passes.

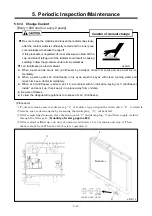

5.5 Periodic Replacement of Parts

Part Name

Part Number

Quantity

Element kit for engine oil filter

(For Main/By-pass)

MITSUBISHI ME180514

1

Compressor oil filter

37438 05400

1

32143 15900 (inner cyl.)

“

1

”

2

Air filter element (engine

・

compressor)

32143 16000 (outer cyl.)

“

2

”

2

Fuel filter

43541 00900

1

Separator

“

1

”

34220 10502

1

Oil separator

Gasket

“

2

”

34235 06700

2

Fuel feed pump gasket

43531 00700

3

Element for fuel pre-filter

43541 01400

1

Clean

Change

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......