5. Periodic Inspection/Maintenance

5

-

15

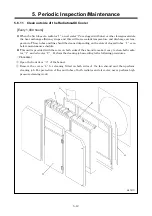

5.6.15 Change Oil Separator

[Every 2,000 hours]

(Procedure)

①

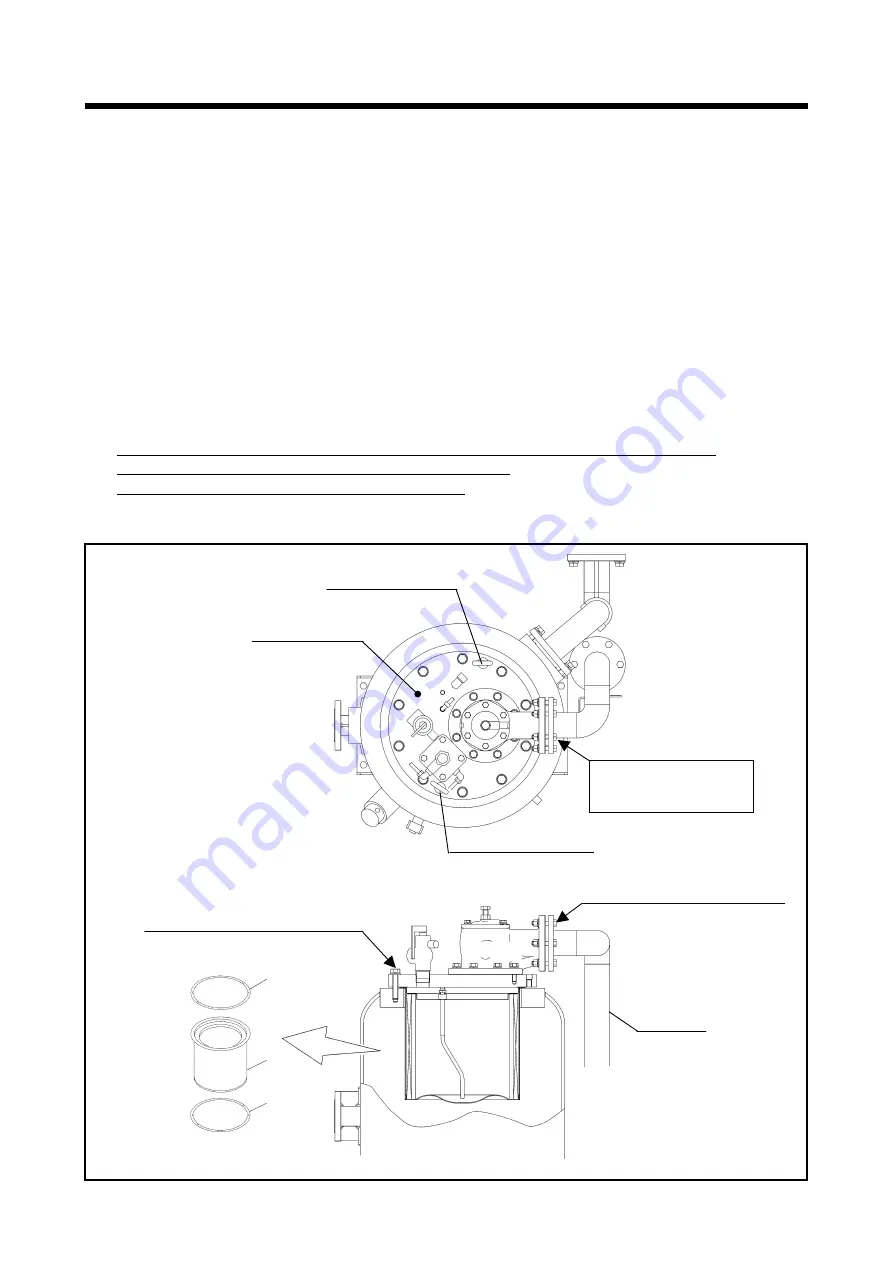

In order to pull out the separator, remove the bolts (14 pieces) fixing the top cover on the separator

cover.

②

Remove the nylon tubes fitted on the piping of separator cover, using a spanner etc.

③

Remove the air pipe, by loosening the fixing bolts (6pcs) of the air pipe.

④

Remove the fixing bolts (10pcs.) of separator cover, using an impact wrench etc.

⑤

Screw two lifting eyebolts for the two threaded holes provided on the separator cover.

⑥

Pass a rope or wire rope through the eyes of the lifting bolts and lift the separator up by a crane etc.

If even before scheduled interval of 2,000 hours operation, consumption of compressor oil is

unusually high. and the differential pressure gauge of the oil separator reaches Red range, change

the oil separator

.(Refer to 4.5.6)

But note that the differential pressure gauge shows correct

indication only in full load operation and minimum pressure.

When replacing oil separator “1”, be sure to replace gasket “2” too.

(For part numbers, refer to 5.5.)

The oil separator “1” is made from electrically conducting material in order to be anti-static.

Also gaskets “2” is treated for conduction by using staplers.

Make sure to use our genuine parts for replacement.

When replacing oil separator, contact directly us or distributor because it requires expert technical

knowledge.

2

1

2

Tightening torque of the bolts

115N-m(1,150kgf-cm)

Lifting bolt (M16)

Separator cover

These 6pcs. bolts

should be removed.

Lifting bolt (M16)

A070130-1

Air pipe

Tightening torque of the bolts

115N-m(1,150kgf-cm)

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

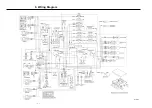

Page 61: ...9 Wiring Diagram 9 1 A090360E...

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......