6. Maintenance/Adjustment

6

-

3

6.2 Troubleshooting

Should any trouble occur during operation, do not leave it. Investigate the cause and take appro-

priate measures.

Read the manual carefully and fully understand what to do in case of trouble.

The better you understand the construction and function of the unit, the faster you can find a prob-

lem and solution.

This chapter describes the state, cause and countermeasures of important troubles in detail:

Symptom Cause

Countermeasures

Low starter

revolution speed.

(1) Battery malfunction.

Check battery

→

Charge, change

Starter rotates but engine

does not start.

(1) Fuel filter clogging.

(2) Malfunction of fuel cut sole-

noid.

Disassemble, clean, and

change

Check fuse

Discharge air pressure will

not rise.

(1) Pressure regulator insufficient

adjustment.

(2) Starting unloader valve is left

at its start position.

(3) Manually operated relief valve

is kept open.

Re-adjust (Fasten)

Place it at “RUN” position

Check/ Re-adjust

Engine does not reach its

maximum speed.

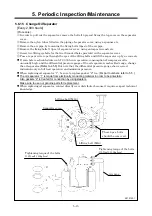

(1) Improper length in speed

regulator rod.

(2) Faulty speed regulator.

(3) Fuel filter clogging.

(4) Engine trouble.

(5) Unloader orifice clogging.

Re-adjust

(

longer length

)

Disassemble/Check

Disassemble/Change

Call your nearest dealer

Disassemble/Clean

While the discharge pressure

will not rise up to the speci-

fied one, RPM will drop.

(1) Pressure regulator insufficient

adjustment.

(2) Trouble of pressure regulator.

Re-adjust (Fasten)

Change

Engine does not reach mini-

mum revolution at

unload.

(1) Improper length in speed

regulator rod.

(2) Faulty speed regulator.

Re-adjust( Shorter length

makes the speed drop/longer

length makes it rise.)

Disassemble/Check

Safety valve

relieves at unload.

(1) Pressure regulator insufficient

adjustment.

(2) Unloader regulator insufficient

adjustment.

(3) Unloader valve damaged and

seat malfunction.

(4) Faulty safety valve.

Re-adjust(loosen)

Re-adjust

Change

Change

Oil mixes in Air.

(Poor oil separation)

(1) Scavenging orifice strainer

clogging.

(2) Low discharge pressure.

(3) Oil separator deteriorated.

Disassemble/Clean

Disassemble/pressure

control valve/check

Change

Insufficient free air delivery.

(1) Air filter element clogging.

(2) Unloader valve cannot fully

open.

(3) Engine does not reach rated

speed.

Clean element or change

Call your nearest dealer

Summary of Contents for PDSE900S-4B1

Page 1: ......

Page 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

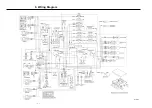

Page 61: ...9 Wiring Diagram 9 1 A090360E...

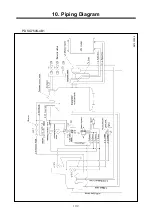

Page 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Page 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Page 67: ......