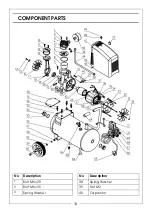

19

4

Cylinder Head

41

Tooth Washer 8

5

O Ring

42

Screw St3.9x12

6

Valve Plate assembly

43

Washer 4

7

Cylinder Seals

44

Discharge Tube

8

Cylinder

45

Elbow Connector

9

Connection Stud

46

Air Filter

10

Screw M5×16

47

Fan Cover

11

Connecting Rod Cover

48

Big Washer 8

12

Piston Ring

49

Screw

13

Connecting Rod

50

Base Board

14

Bolt M6×16

51

Bolt M8×25

15

Big Washer 6

52

Washer 8

16

Fan

53

Flange Nut M8

17

Bolt M4×20

54

Plug

18

Spring Washer 4

55

O Ring

19

Bearing 6005-2RS

56

24L Tank

20

Pin 4 x14

57

Nut M8

21

Crank

58

Spring Washer 8

22

Screw M8×35-left

59

Wheel

23

Crankcase

60

Axle

24

Bearing 6204-RS

61

Check Valve

25

Rotor

62

Drain Valve 1/4 Inch

26

Stator assembly

63

M8 x 30 bolt

27

Bearing 6202

64

Absorber

28

Corrugated Washer

65

Power Cable

29

Motor Bracket

66

Quick Coupler

30

Circlip 14

67

Regulator Valve

31

Fan

68

Pressure Gauge

32

Bolt M5×105

69

Safety Valve

33

Spring Washer

70

Pressure Switch

34

Screw M4×10

71

Release Pipe

35

Spring Washer 4

72

Thermal Protector

36

Tooth Washer 4

37

Screw M3×6

Summary of Contents for 2244030

Page 17: ...17 DECLARATION OF CONFORMITY ...

Page 20: ......