15

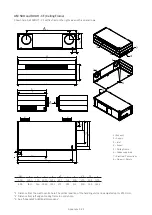

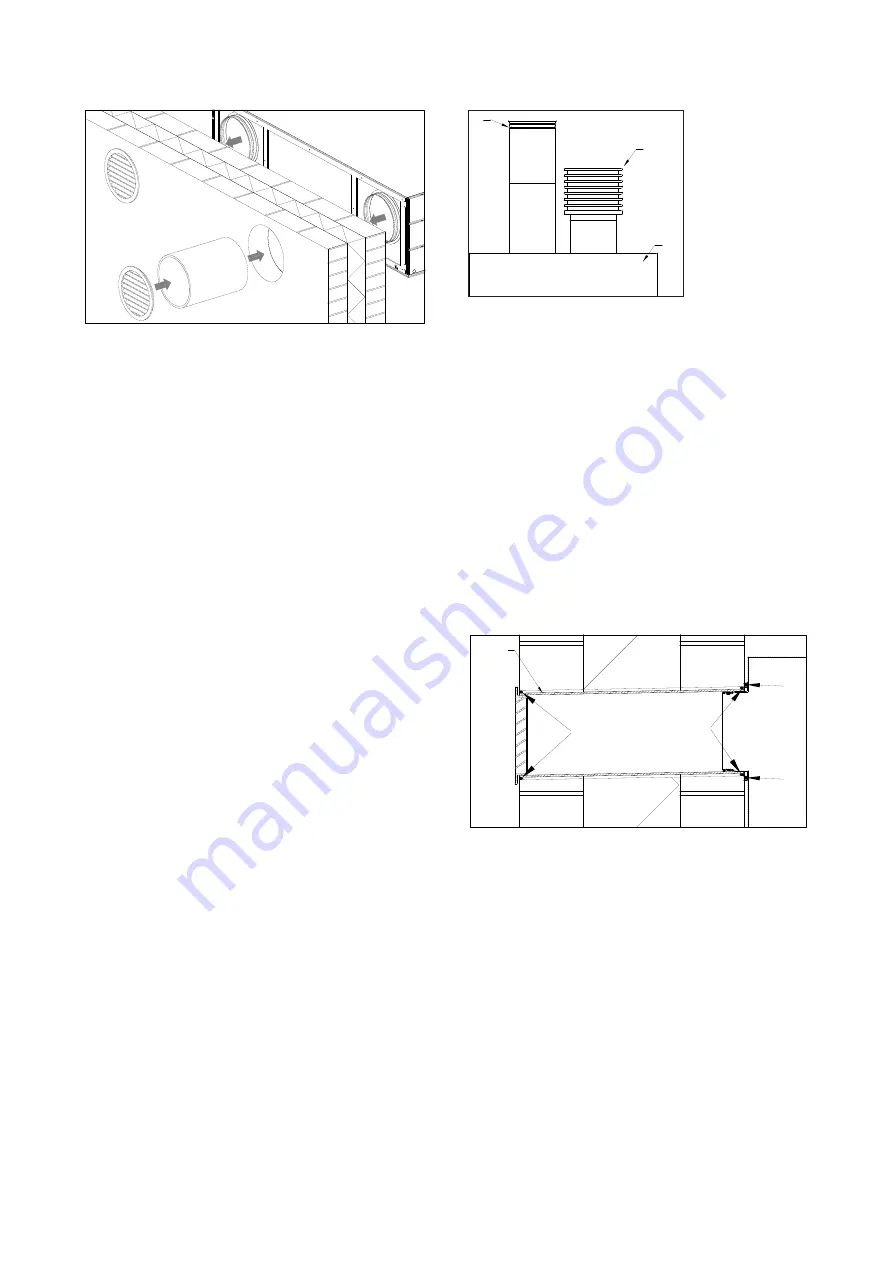

3.7. Ducts and Grilles

The materials needed and method of fitting the ducting

depend on the unit, the options chosen and the customer’s

order. For this reason, we can provide only general instruc-

tions for fitting the ducts.

The length of the ducting is calculated on the basis of the

thickness of the wall/dimensions of the roof.

Please note that the duct holes in the wall must have an

outward downward gradient of 1-2% to prevent heavy rain

from entering the unit.

Exhaust air ducts and supply air ducts must be insulated

against condensation on the ducts, if they are within the

building envelope. The extract air ducts and inlet air ducts

must be insulated against temperature loss and condensa-

tion forming inside the ducts if they are mounted outside

the building envelope, or run through an unheated room.

Condensation and heat insulation should be performed

according to standards and rules in effect.

Fire requirements according to standards and rules in

effect must be observed.

The installation of ventilation ducts should be performed

according to standards and rules in effect.

Exhaust air ducts and supply air ducts must be insulated

against noise if they are visible.

Finally, fit a suitable circular grille with the slats pointing

downwards on the outside of the outer wall or a roof cap

up on the roof.

To avoid an increase in noise level, it is important that the

ducts should not get twisted or compressed against the

exhaust air spigot and supply air spigot of the unit.

Remember to seal around the penetrations. See section

“Sealing the Gaps Around Ducts”.

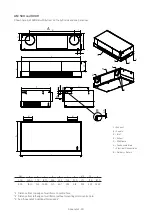

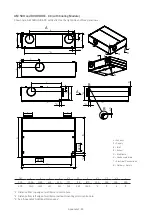

3.8. Roof Cap

2

3

1

Fit roof caps on the roof to finish off the installation of

exhaust and supply through a roof. Installation will depend

on the roof construction (3). The illustration shows which

roof caps are for exhaust (1) and intake (2).

Fire requirements for the installation of multiple systems

must be observed according to the standards and rules

in effect.

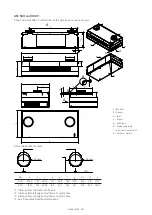

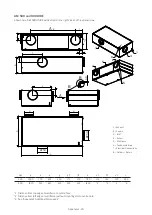

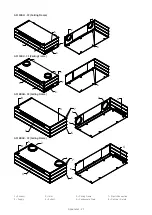

3.9. Sealing the Gaps Around Ducts

Sealing of the gaps around ducts is performed as shown in

the sectional drawing below.

1

2

3

5

2

5

4

4

Application of a seal (shown here on a model with wall ducts)

is important at the ducts (3) indside and the outside edges

(4) in order to prevent draughts between the unit (1) and

the wall/roof (2) as well as between the ducts (3) and the

wall/roof (2).

Sealing on the inside between the pipes (3) and the wall/

ceiling (2) can also be performed between the air handling

unit (1) and the wall/roof (2) at position (5) before fitting the

air handling unit.

Depending on the condition of the wall/ceiling and the

dimensions of the air handling unit, a sealant that retains

elasticity over the long term or expanding sealing tape

can be used to obtain a flexible seal. This material is to be

applied to the rear of the unit around the air connection

fittings, or at the side of the duct holes on the wall to even

out irregularities on the wall/ceiling.